Organic waste gas desorption process

An organic waste gas and desorption technology, which is applied in the petroleum industry, combustible gas purification, combustible gas purification/transformation, etc., can solve the problems of high acid content in discharge water, reduced service life of materials, and great corrosion of equipment, etc., to achieve Improve the efficiency of adsorption and desorption, improve the service life of equipment, and solve the effect of acid corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

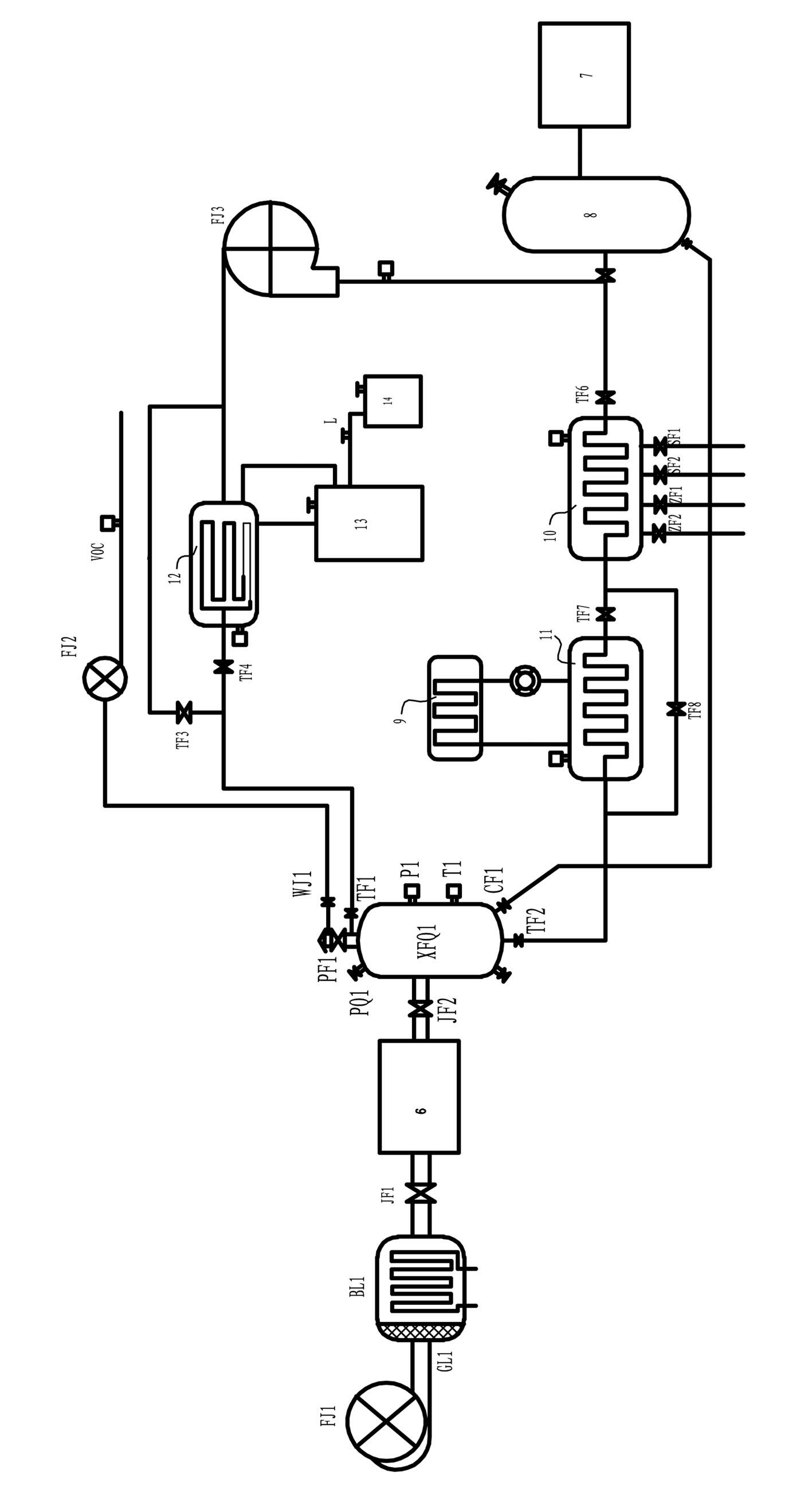

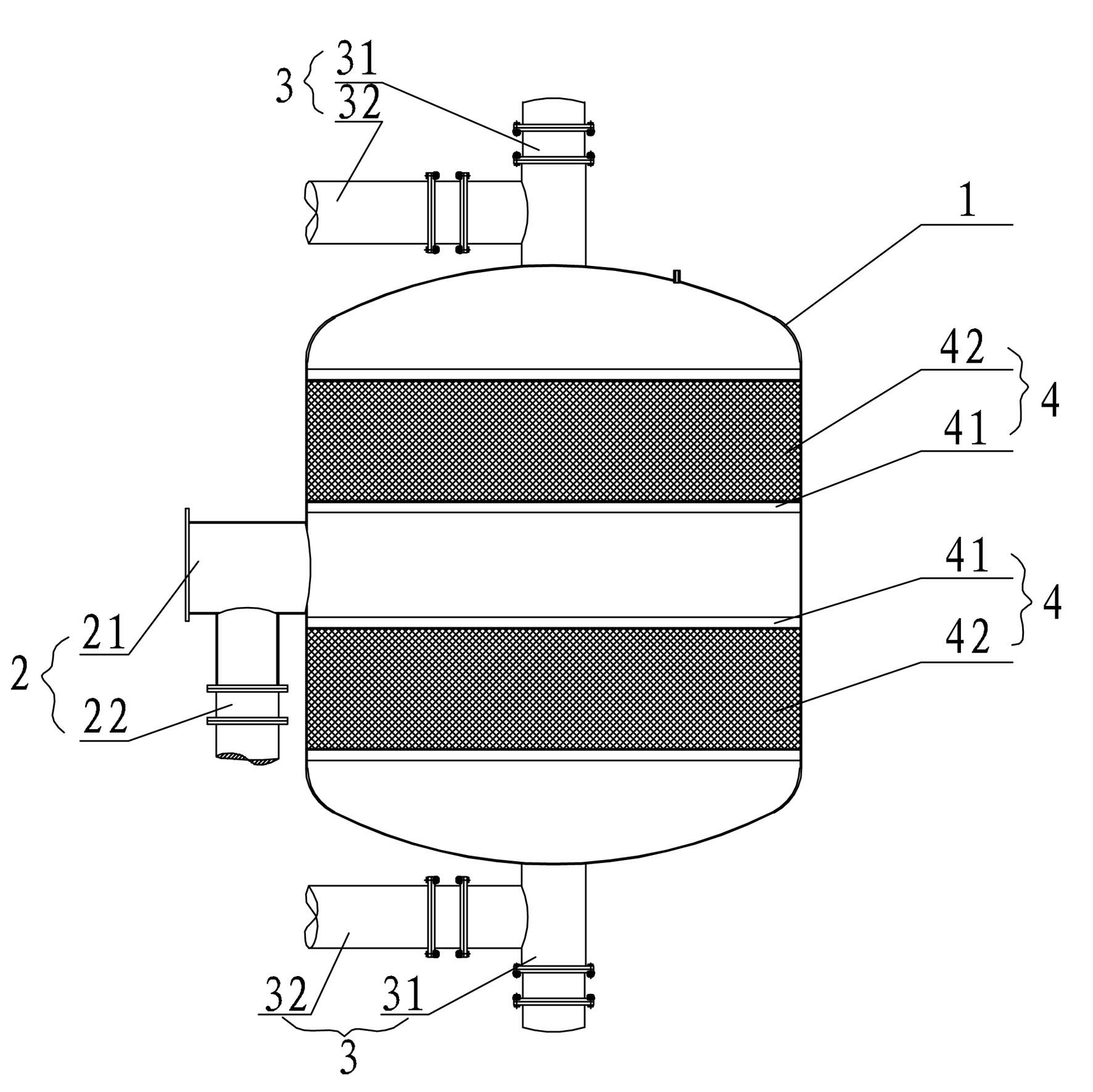

[0019] The process of nitrogen desorption, such as figure 1 The adsorption and desorption method of "one inlet and two outlets" is adopted as shown. Among them, the so-called "one inlet and two outlets" adsorption and desorption method mainly means that the adsorber XFQ1 adopts the structure of one inlet and two outlets, such as figure 2 As shown, the adsorber includes a hollow tank body 1, an air intake pipe 2 and an exhaust pipe 3 communicating with the inside of the tank body 1, wherein the air intake pipe 2 consists of a waste gas intake pipe 21 and a desorbed gas intake pipe that can be opened and closed. 22. For example, valves are provided on the exhaust gas inlet pipe 21 and the desorbed gas inlet pipe 22 to realize the on-off control of the exhaust gas inlet pipe 21 and the desorbed gas inlet pipe 22. In order to make the overall structure compact, the exhaust gas The intake pipe 21 and the desorbed gas intake pipe 22 can be connected by a three-way valve; there are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com