Recycled concrete produced from construction wastes and production method thereof

A technology for recycling concrete and construction waste, applied in the field of building wall materials, can solve the problems of fluctuation in the performance of recycled concrete, incompatibility with the design of the proportion of recycled coarse aggregate from waste bricks, high water absorption, etc., so as to enhance work performance and increase resources. The effect of recycling utilization and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

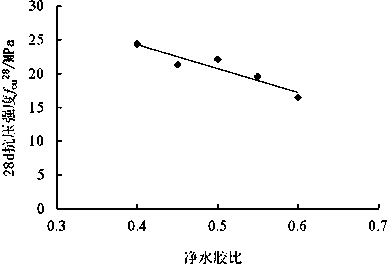

[0046] A kind of recycled concrete produced with construction waste as raw material. The concrete with strength grade of C10-C20 is made by mixing recycled coarse aggregate, recycled fine aggregate, cementitious material and water. The recycled concrete described per cubic meter The content of each component is: recycled coarse aggregate 650~770kg / m 3 ;Regenerated fine aggregate 576~764kg / m 3 ;Cementitious material 267~400kg / m 3 ;Water 255~345kg / m 3 , the sand rate of the recycled concrete is 43%-51%, and the recycled concrete is used for the manufacture of wall panels or walls that do not require high strength.

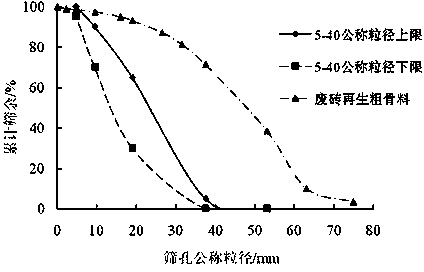

[0047] Regenerated coarse aggregate is made from waste bricks after slight crushing and screening, the particle size is 5-80mm, and the apparent density of the regenerated coarse aggregate is 1550-1700kg / m 3 , The bulk density is 750~800kg / m 3 , The porosity is 45-55%, the water absorption is 15-17%, and the crushing index is 35-45%.

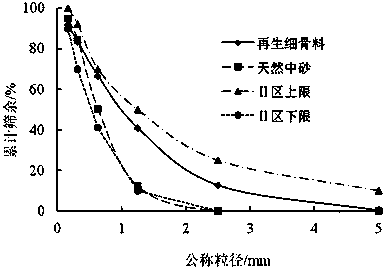

[0048] Regenerated fine ag...

Embodiment 2

[0085] It is the recycled concrete of C10 that preparation is used for the strength class of prefabricated wall board board core, repeats embodiment one, has following difference:

[0086] The content of each component per cubic meter is as shown in Table 7,

[0087] Table 7

[0088]

[0089] Mix and stir according to the content of each component per cubic meter described in Table 7. The mixing and stirring method adopts the mixing process of adding additional water to the recycled coarse aggregate in advance and stirring twice in stages. The prepared phase strength grade is C10 recycled concrete.

[0090] The elastic modulus of the recycled concrete with strength grade C10 is 0.970×10 4 MPa, the compressive strength of the 28d cube is 12.83MPa, which meets the strength performance requirements of the prefabricated wallboard core.

Embodiment 3

[0092] It is the recycled concrete of C15 that preparation is used for the strength class of prefabricated wall board board core, repeats embodiment one, has following difference:

[0093] The content of each component per cubic meter is as shown in Table 8,

[0094] Table 8

[0095]

[0096] Mix and stir according to the content of each component per cubic meter described in Table 8. The mixing and stirring method adopts the mixing process of adding additional water to the recycled coarse aggregate in advance and stirring twice in stages. The strength level of the prepared phase is C15 recycled concrete.

[0097] The elastic modulus of the recycled concrete with strength grade C15 is 1.219×10 4 MPa, the compressive strength of the 28d cube is 17.21MPa, which meets the strength performance requirements of the prefabricated wallboard core.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com