Method for preparing 2,6-dichlorotoluene by catalyzing o-chlorotoluene with ionic liquid

An ionic liquid, dichlorotoluene technology, applied in chemical instruments and methods, halogenated hydrocarbon preparation, organic chemistry and other directions, can solve the problems of difficult separation and purification of products, difficulty in selecting chlorination, low comprehensive yield, etc., and achieves good industrial performance. Application value, easy product separation, high conversion rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: A preparation of 2,6 by selective chlorination of o-chlorotoluene – The method of dichlorotoluene comprises the following steps:

[0025] 1) Ionic liquid [BMIM]Cl-2AlCl 3 Preparation of N 2 Under protection, 0.65 mol of 1 – Methylimidazole and 0.7 mol of chlorobutane were stirred and mixed in a 250 mL three-necked flask with a condenser, and the temperature was raised to 80 °C for 48 h under reflux. The product was separated by a separatory funnel, the unreacted liquid was removed, and then washed 3 times with 20 mL of ethyl acetate. The crude product was evaporated under vacuum at 60 °C to remove residual ethyl acetate, and dried in vacuum at 70 °C for 24 h. The obtained light yellow liquid was [BMIM]Cl ionic liquid intermediate, which was stored in dry N 2 Reserve under atmosphere.

[0026] 2) N 2 In the atmosphere, at 120 °C, 34.92 g (0.2 mol) of the intermediate prepared above and 53.6 g (0.2 mol) of anhydrous AlCl 3 Add to a three-necked flask, s...

Embodiment 2

[0035] Example 2: A preparation of 2,6 by selective chlorination of o-chlorotoluene – The method of dichlorotoluene comprises the following steps:

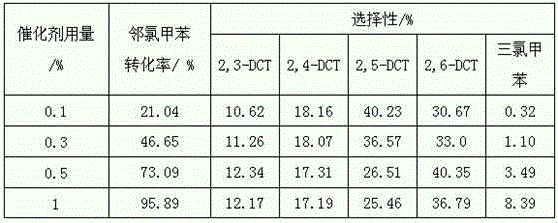

[0036] Adopt the same method of implementation 1 to prepare chloroaluminate ionic liquid, and the chlorination reaction process of o-chlorotoluene adopts the same method of implementation 1, but change [BMIM]Cl-2AlCl 3 The amount of ionic liquid is 0.05 g, 0.15 g, 0.5 g, to explore [BMIM]Cl-2AlCl 3 The impact of the consumption of ionic liquid on o-chlorotoluene chlorination process, as table 2:

[0037] Table 2 [BMIM]Cl-2AlCl 3 Effect of the dosage of ionic liquid on the chlorination of o-chlorotoluene

[0038]

[0039] It can be seen from Table 2 that with the increase of the amount of catalyst, the reaction rate of o-chlorotoluene is gradually accelerated, and the selectivity of 2,6-dichlorotoluene increases first and then decreases. Among them, when the catalyst dosage is 0.5%, the selectivity of 2,6-dichlorotolue...

Embodiment 3

[0040] Example 3: A preparation of 2,6 by selective chlorination of o-chlorotoluene – The method of dichlorotoluene comprises the following steps:

[0041] Adopt the same method of implementation 1 to prepare chloroaluminate ionic liquid, the chlorination reaction process of o-chlorotoluene adopts the same method of implementation 1, but change the reaction temperature to 50 ℃ and 70 ℃, and explore the chlorination process of o-chlorotoluene at different reaction temperatures The impact, as shown in Table 3:

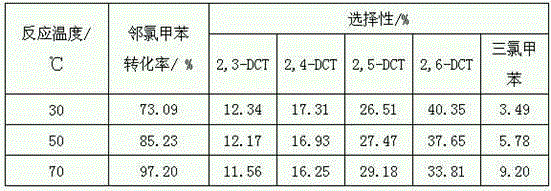

[0042] Table 3 Effect of different reaction temperatures on the chlorination of o-chlorotoluene

[0043]

[0044] It can be seen from Table 3 that as the reaction temperature increases, the reaction rate increases, while the selectivity of the by-product trichlorotoluene gradually increases, which in turn leads to a gradual decrease in the selectivity of 2,6-dichlorotoluene. Among them, when the reaction temperature is 30℃, the selectivity of 2,6-dichlorotolue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com