Method for selectively preparing o-chlorotoluene

An o-chlorotoluene and selectivity technology, which is applied in the field of selective preparation of o-chlorotoluene, can solve the problems of difficult separation, complicated catalyst preparation, insufficient ortho-chlorination selectivity, etc., and achieves the effect of improving the selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

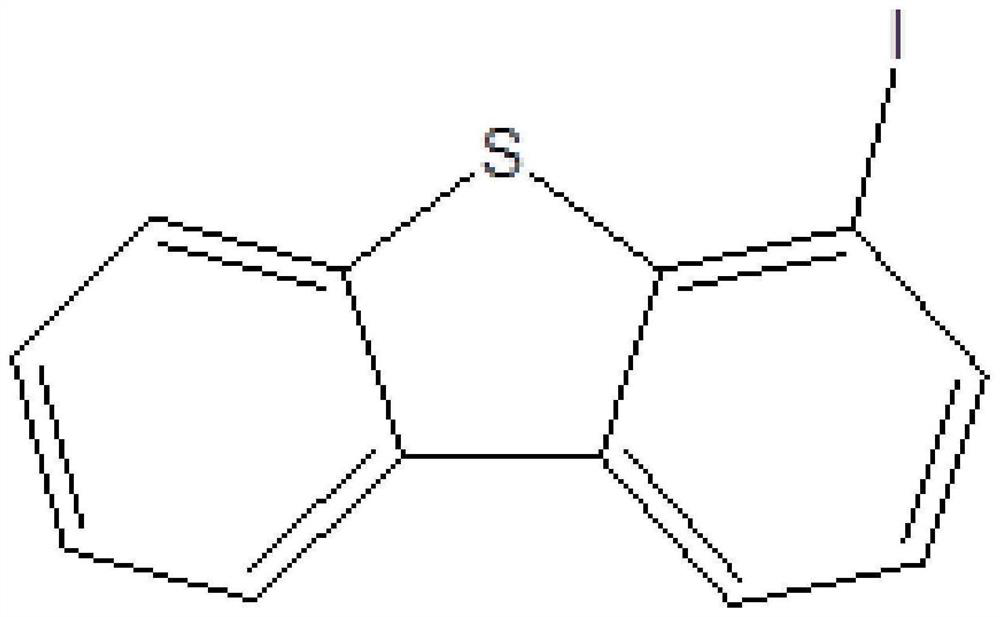

[0031] Add 30 mg of iron powder and 30 mg of 4-iododibenzothiophene (0.1% of the mass of toluene) into 30 ml of toluene, and under the condition of avoiding light and 35 ° C, uniformly and slowly pass in chlorine gas for about 7 hours, and take samples during the reaction. Gas chromatography detection. After the chlorination is finished, the toluene monochlorination mixed liquid component detection result is as follows: the transformation rate of toluene 99.81%, o-chlorotoluene content 68.50%, p-chlorotoluene content 30.08%, meta-chlorotoluene content 0.05%, the sum of polychlorinated toluene content was 1.18%.

Embodiment 2

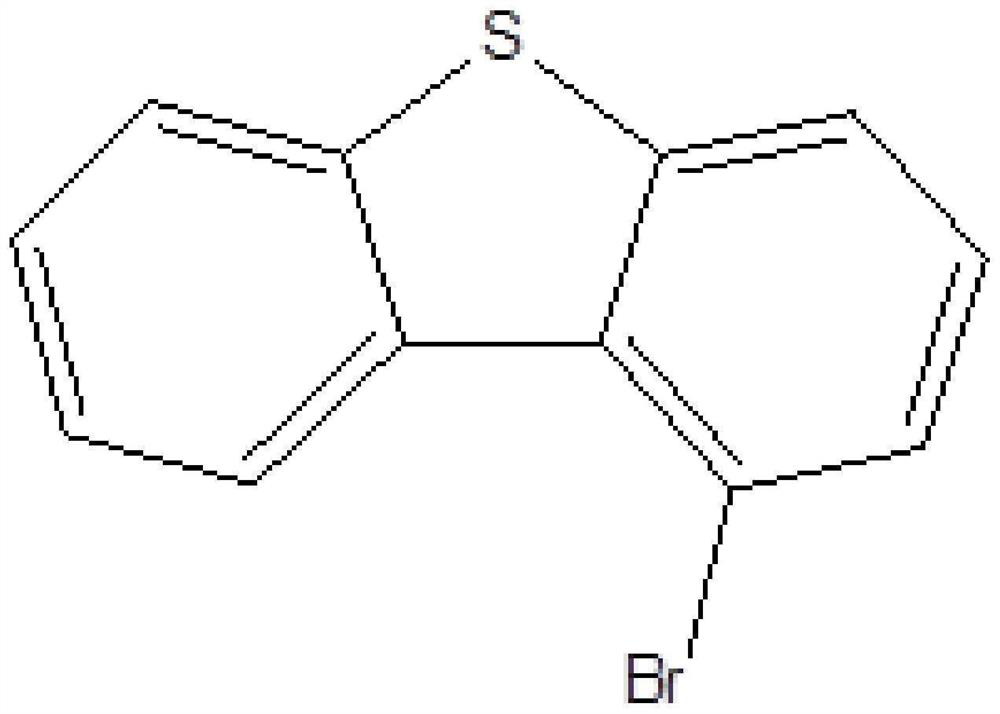

[0033] 30 mg of iron powder and 15 mg of 1-bromodibenzothiophene (0.05% of the total mass of toluene) were added to 30 ml of toluene, and under the condition of avoiding light and 30°C, chlorine gas was uniformly and slowly introduced for about 8 hours, and samples were taken during the reaction. Gas chromatography detection. After the chlorination finishes, the toluene monochlorination mixed liquid component detection result is as follows: the conversion rate of toluene 99.28%, o-chlorotoluene content 63.69%, p-chlorotoluene content 33.30%, meta-chlorotoluene content 0.08%, the sum of polychlorinated toluene content was 2.21%.

Embodiment 3

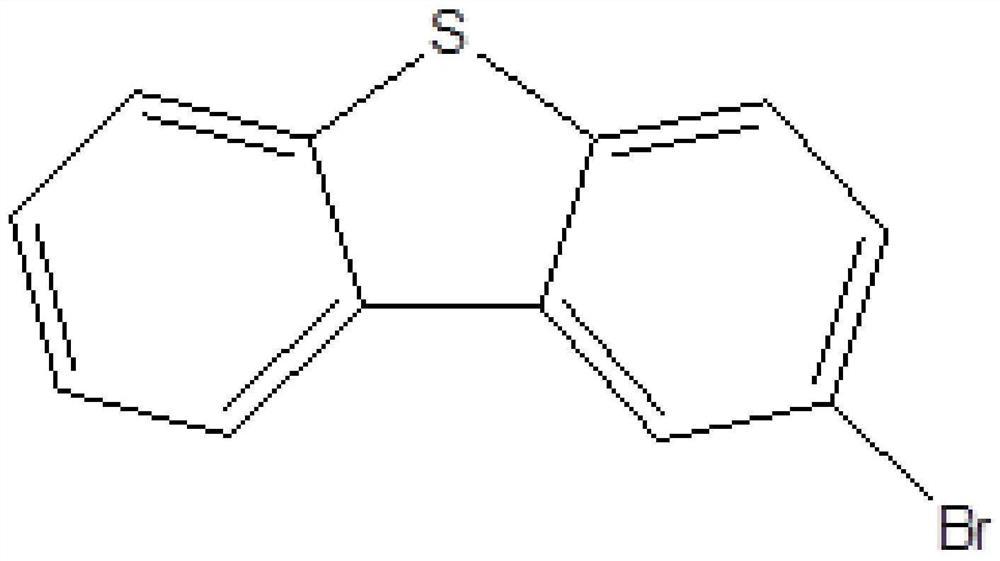

[0035] 30mg of iron powder and 30mg of 2-bromodibenzothiophene (0.1% of the total mass of toluene) were added to 30ml of toluene, under the condition of avoiding light and 30°C, chlorine gas was evenly and slowly passed in for about 8 hours, and samples were taken during the reaction. Gas chromatography detection. After the chlorination finishes, the toluene monochlorination mixed liquid component detection result is as follows: the conversion rate of toluene 99.63%, o-chlorotoluene content 58.29%, p-chlorotoluene content 40.05%, meta-chlorotoluene content 0.15%, the sum of polychlorinated toluene content was 1.14%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com