Method for producing 2,6-dichlorotoluene and 2,3-dichlorotoluene by utilizing 2-chlorotoluene to directionally chloridize

A kind of technology of dichlorotoluene and chlorotoluene, which is applied in the field of producing 2,6-dichlorotoluene and 2,3-dichlorotoluene by directional chlorination of 2-chlorotoluene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

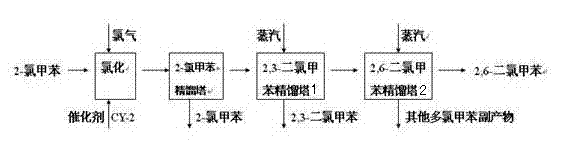

[0016] Depend on figure 1 Known, the method for producing 2,6-dichlorotoluene and 2,3-dichlorotoluene with 2-chlorotoluene directional chlorination comprises the following steps:

[0017] 1. Add directional chlorination catalyst: add 4500±10kg of 2-chlorotoluene into a 5000L open enamel reactor through a metering tank, add 5±0.5kg of directional chlorination catalyst (self-developed: CY-2), and start stirring The catalyst is evenly distributed in the material, and the tail gas absorption circulating water pump is turned on to absorb the tail gas generated after the reaction.

[0018] The directional chlorination catalyst (CY-2) used in the present invention is produced by the following method:

[0019] Add 300±5kg of xylene into a 500L enamel reaction kettle equipped with a water separation device, heat and reflux to remove a small amount of water in the xylene, cool down to 40±3°C, add 30±1kg of activated clay (100-200 mesh, dry at 120°C for 2±0.1 hours and then cool to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com