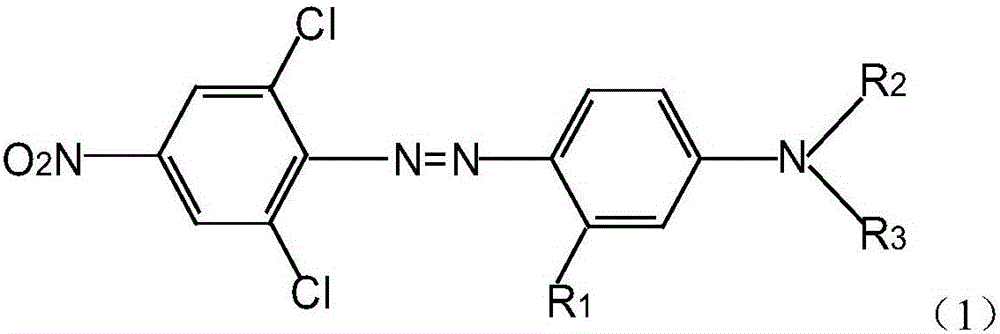

Disperse dye composition, and preparation method and application thereof

A technology of disperse dyes and compositions, applied in dyeing methods, organic dyes, textiles and papermaking, etc., can solve the problems of affecting the ecological environment, failing to meet environmental protection requirements, loss of printing and dyeing plants, etc., achieving convenient use and saving environmental protection processing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

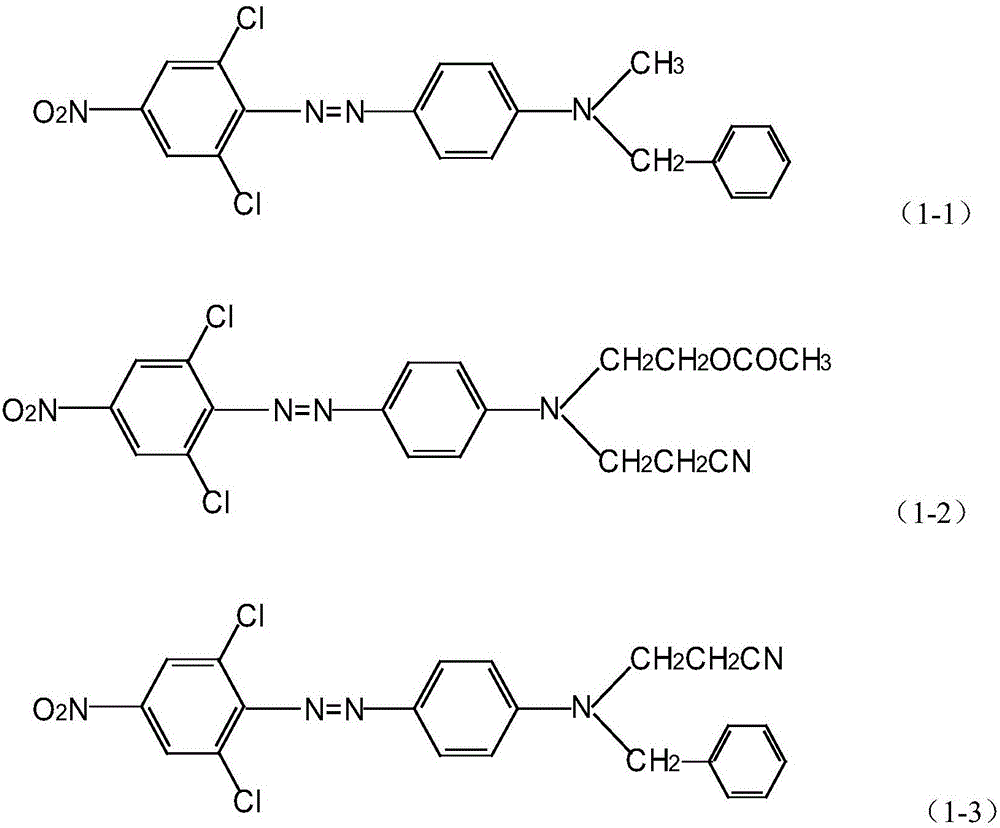

preparation example 1

[0043] (1) Add sulfuric acid to the diazo kettle, start stirring, then slowly add nitrosyl sulfuric acid, control the temperature not to exceed 40°C, after adding, cool down to 23°C, slowly and evenly add 2,6-dichloro-4- After adding nitroaniline, heat it at 25-30°C for 4 hours to obtain diazo solution, add water and ice to the diazo dilution kettle, cool down to below 5°C, press into the diazo solution to dilute, and control the dilution temperature. After the pressure is over 5°C, add diatomaceous earth, stir for 30 minutes, filter, and pour the filtrate into the coupling kettle.

[0044] (2) Turn on the coupling tank and stir, add ice, urea and flat, stir for 15 minutes, add isooctyl alcohol, control the temperature below 10°C, add the coupling component N-methyl-N-benzylaniline dropwise, add dropwise After adding for 4 hours, control the reaction temperature at 10-15°C, keep the reaction for 2 hours after dropping, slowly raise the temperature to 60°C for crystallization, ...

preparation example 2

[0046] (1) Add sulfuric acid to the diazo kettle, start stirring, then slowly add nitrosyl sulfuric acid, control the temperature not to exceed 40°C, after adding, cool down to 25°C, slowly and evenly add 2,6-dichloro-4- After adding nitroaniline, heat it at 25-30°C for 8 hours to obtain diazo solution, add water and ice to the diazo dilution kettle, cool down to below 5°C, press into the diazo solution to dilute, and control the dilution temperature. When the pressure is over 5°C, add diatomaceous earth, stir for 60 minutes, filter, and pour the filtrate into the coupling kettle.

[0047] (2) Turn on the coupling tank and stir, add ice, urea and flat, stir for 60 minutes, add isooctyl alcohol, control the temperature below 10°C, add the coupling component N-cyanoethyl-N-acetoxyethylaniline dropwise , dropwise for 5 hours, after the addition, control the reaction temperature at 10-15°C, keep the reaction for 3 hours after dropping, slowly raise the temperature to 80°C for crys...

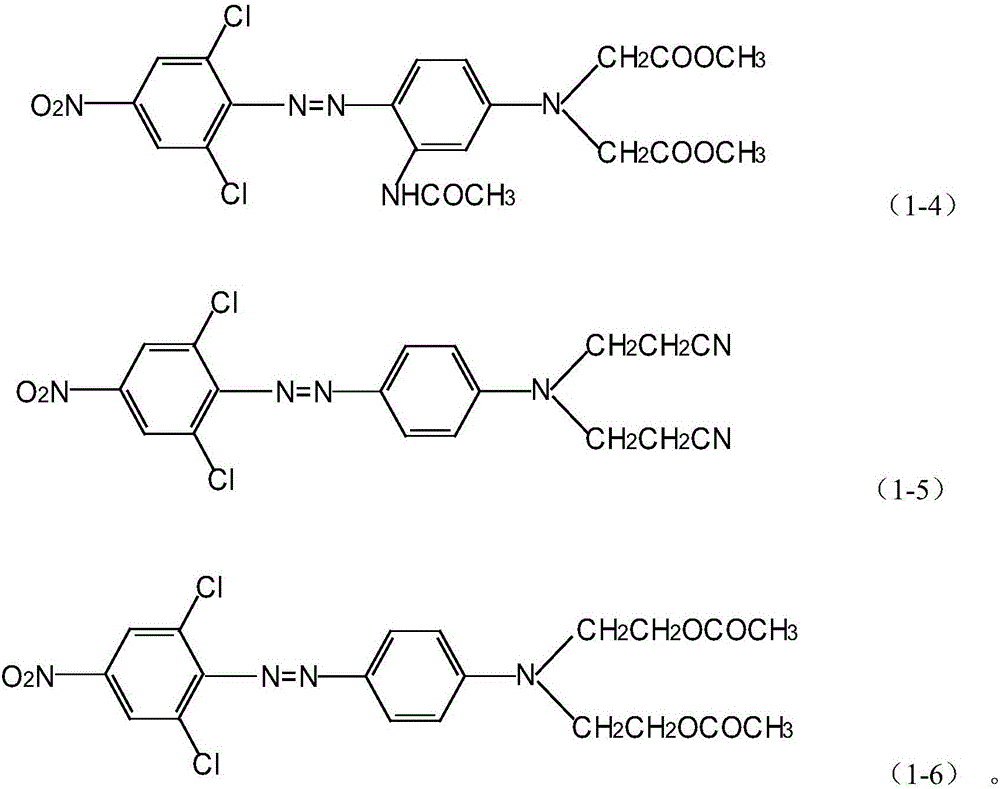

preparation example 3-6

[0049] Adopt the method for Preparation Example 1, the difference is that (1) the coupling component N-methyl-N-benzylaniline in Preparation Example 1 is replaced by the coupling component shown in Table 1; (2) In Preparation Examples 3 and 4, the diatomite in Preparation Example 1 was replaced by activated carbon and bentonite, respectively.

[0050] Table 1

[0051]

[0052] The components A contained in the products (I-3)-(I-6) obtained in sequence from Preparation Examples 3-6 are the compounds of formulas (1-3)-(1-6) in sequence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com