Phosgene producing method and equipment

一种光气、冷却剂的技术,应用在化学仪器和方法、可持续制造/加工、气候可持续性等方向,能够解决腐蚀等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

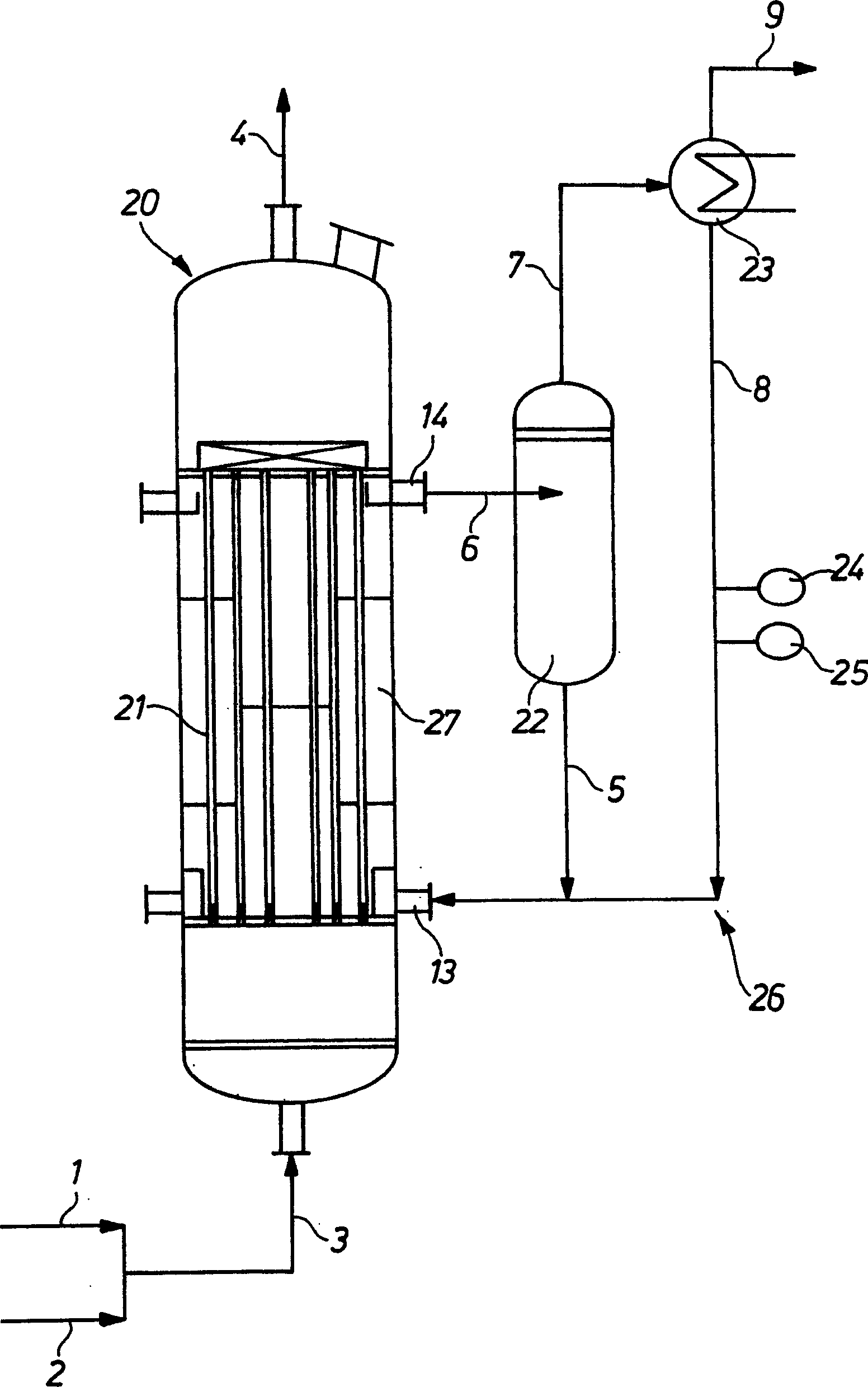

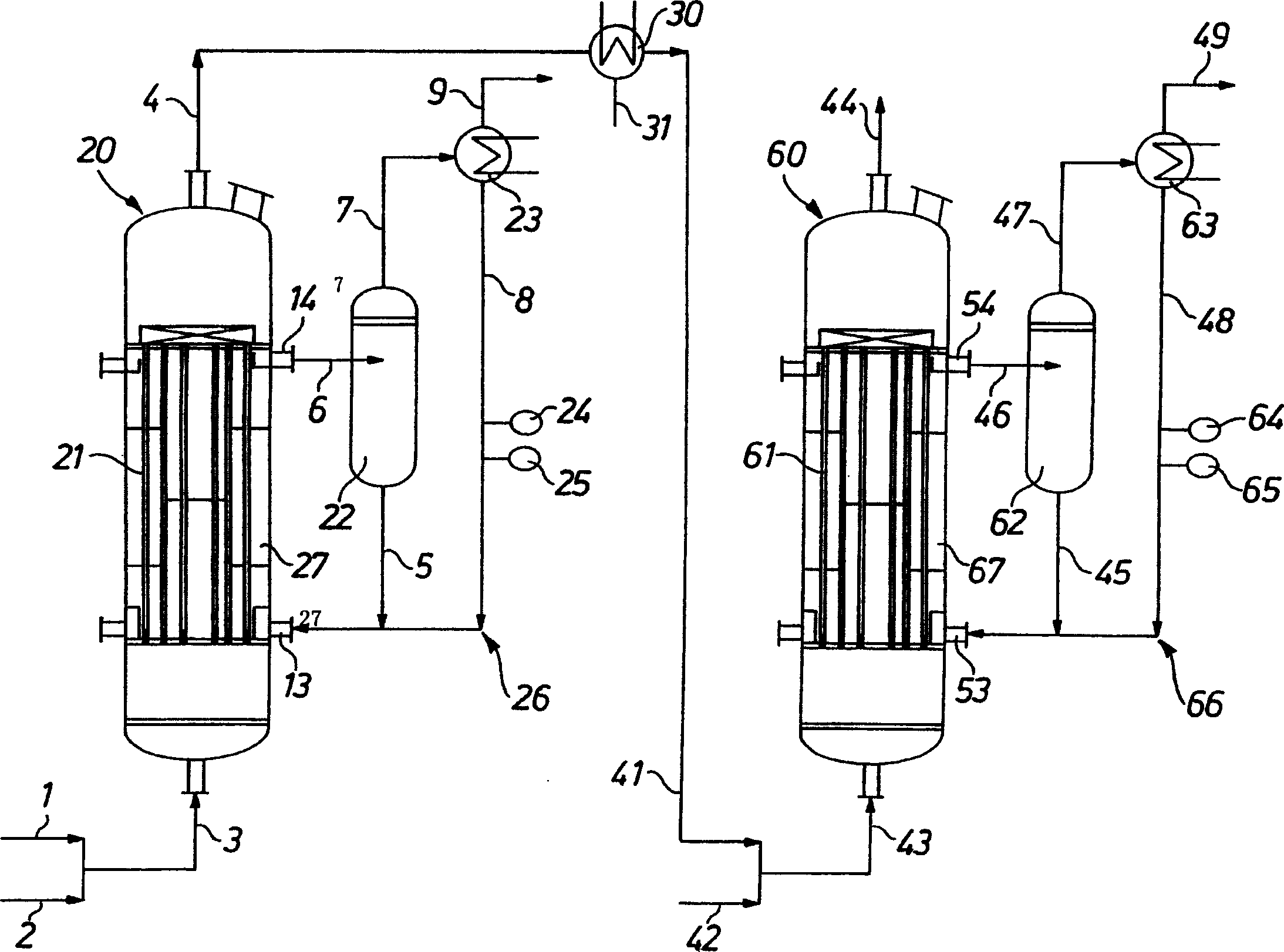

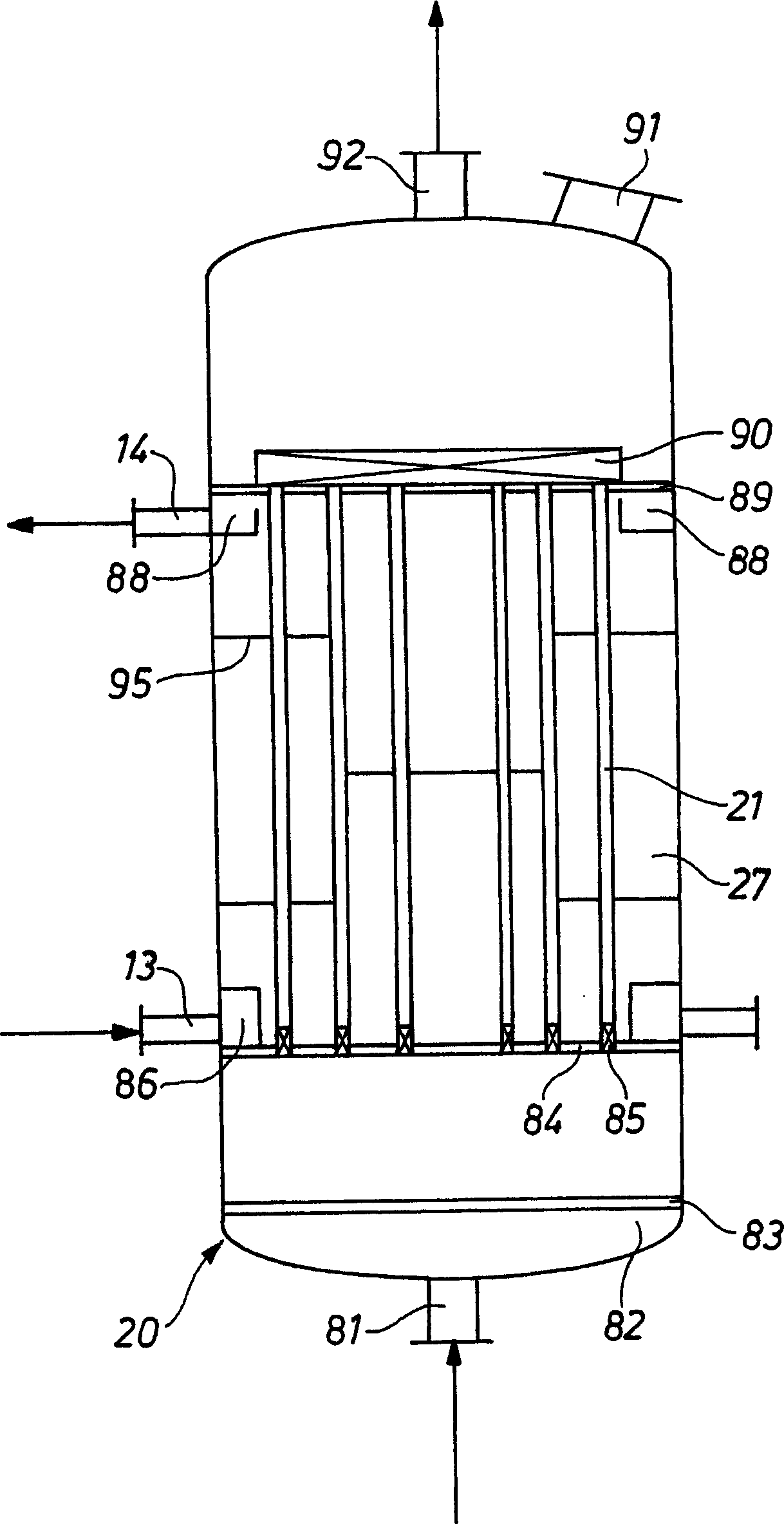

[0020] The feature of the method of the present invention is that the dissipation of the reaction heat of the phosgene production method is realized by evaporative cooling of decompressed water, and the pressure preferably used at this time is lower than atmospheric pressure, and its absolute value is 1 bar.

[0021] From this point of view, the coolant cycle is preferably a closed loop system in which water is evaporated, transferred, condensed at another point, and then recycled to the coolant space for re-evaporation. In this sense, the coolant space in the shell-and-tube reactor preferably contains (at all times) liquid water in boiling state.

[0022] Therefore, the pressure in the reaction space remains greater than the pressure in the coolant space. If the reaction tube is damaged, phosgene will enter the coolant space from the reaction tube, and water will not enter the reaction space from the coolant space (that is, the reaction of the reactor Tube). The coolant spac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com