Hollow glass micro-spheres surface modification method

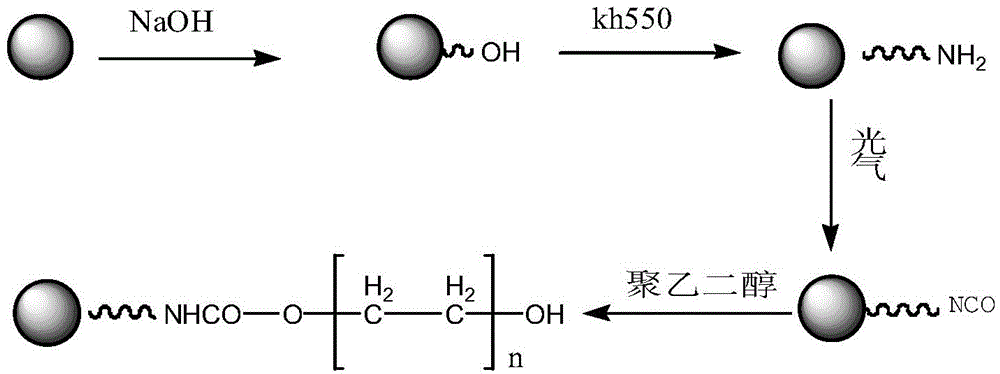

A hollow glass microsphere, surface modification technology, applied in chemical instruments and methods, inorganic pigment treatment, dyed polymer organic compound treatment, etc., can solve the problem of insignificant modification effect, poor compatibility, easy cracking, etc. problems, to achieve the effect of improving mechanical properties, simple operation process, and increasing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Add 5g of K37 purchased from 3M to a 250ml glass beaker, then add 50ml of acetone, stir at room temperature for 3h, filter out the hollow glass microspheres, dry them in an oven at 55°C for 10h, and then transfer them into 250ml In the glass beaker, add 50ml of sodium hydroxide solution with a mass concentration of 25%, stir at room temperature for 5 hours, filter and take out the glass microbeads, then wash with acetic acid solution with a mass concentration of 1%, and finally wash with a large amount of deionized water. Finally, it was dried in a vacuum oven at 80 °C for 10 h. Put the obtained glass beads into 80ml of ethanol-deionized water mixed solution with a volume ratio of 1:1, add 1g of silane coupling agent kh550, stir at room temperature for 5h, then filter and separate the glass beads, and place them at room temperature until After the solution evaporated completely, it was dried in a vacuum oven at 60° C. for 10 h. Move the obtained hollow glass microspher...

Embodiment 2

[0017] Add 5g of K37 purchased from 3M to a 250ml glass beaker, then add 50ml of acetone, stir at room temperature for 3h, filter out the hollow glass microspheres, dry them in an oven at 55°C for 10h, and then transfer them into 250ml In the glass beaker, add 50ml of sodium hydroxide solution with a mass concentration of 25%, stir at room temperature for 5 hours, filter and take out the glass microbeads, then wash with acetic acid solution with a mass concentration of 1%, and finally wash with a large amount of deionized water. Finally, it was dried in a vacuum oven at 80 °C for 10 h. Put the obtained glass beads into 80ml of ethanol-deionized water mixed solution with a volume ratio of 1:1, add 1g of silane coupling agent kh550, stir at room temperature for 5h, then filter and separate the glass beads, and place them at room temperature until After the solution evaporated completely, it was dried in a vacuum oven at 60° C. for 10 h. Move the obtained hollow glass microspher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com