Mixer and method for preparing organic isocyanate

An organic isocyanate and mixer technology, applied in mixers, fluid mixers, chemical instruments and methods, etc., can solve problems such as phosgene leakage, and achieve the effects of reducing the risk of clogging, reducing retention and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

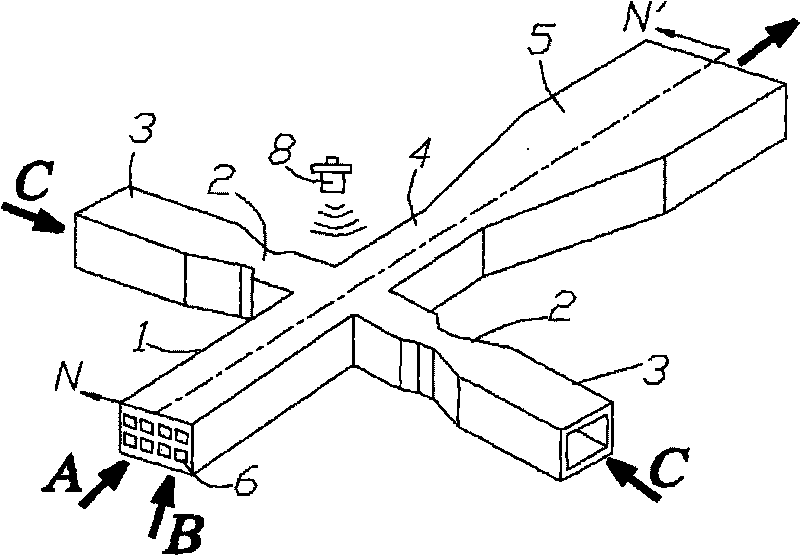

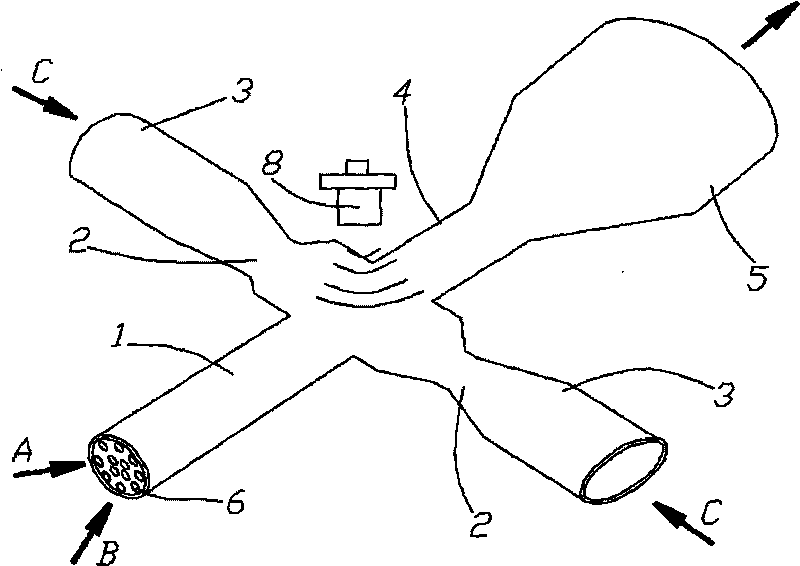

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

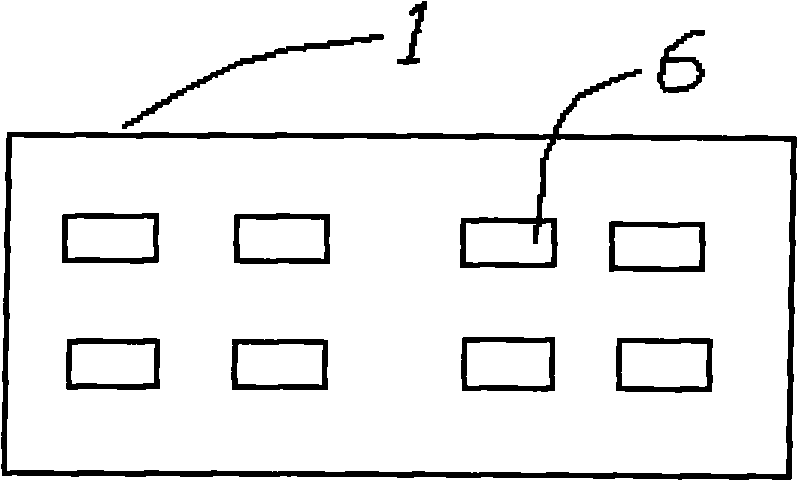

[0033] A mixer comprising a main feed pipe 1, two side feed pipes 3 and a discharge pipe 4; the main feed pipe and the discharge pipe are arranged on the same axis, and the axis of the side feed pipe is connected The axis of the feed pipe is set at 60 degrees (it can also be set at 70 degrees, 80 degrees or 90 degrees), and a mixing chamber 7 is arranged at the confluence of the main feed pipe, side feed pipe and discharge pipe. An ultrasonic generator 8 is arranged outside the chamber, and the ultrasonic wave with a frequency of 80KHz is transmitted to the mixing chamber (the frequency of the ultrasonic wave can also be selected from 20KHz, 60KHz, 100KHz, 150KHz, 180KHz or 200KHz); the main feed pipe is provided with a microchannel 6; The side feed pipe is provided with a constriction 2 near the mixing chamber; the discharge end of the discharge pipe is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com