Method for continuously preparing phosgene

A phosgene and gaseous technology, applied in the direction of carbonyl chloride, etc., can solve the problems of poor heat tracing effect, affecting the working conditions of the separation process, and temperature drop

Inactive Publication Date: 2011-06-15

甘肃银光聚银化工有限公司 +1

View PDF11 Cites 30 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

A new chlorine gas preheater B1 is added to solve the problem of chlorine gas liquefaction due to temperature drop and poor heating effect during the transportation process, resulting in excessive free chlorine content in phosgene, resulting in the formation of Cl-TDI in the photochemical reaction, which seriously affects the separation Problems with process conditions

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

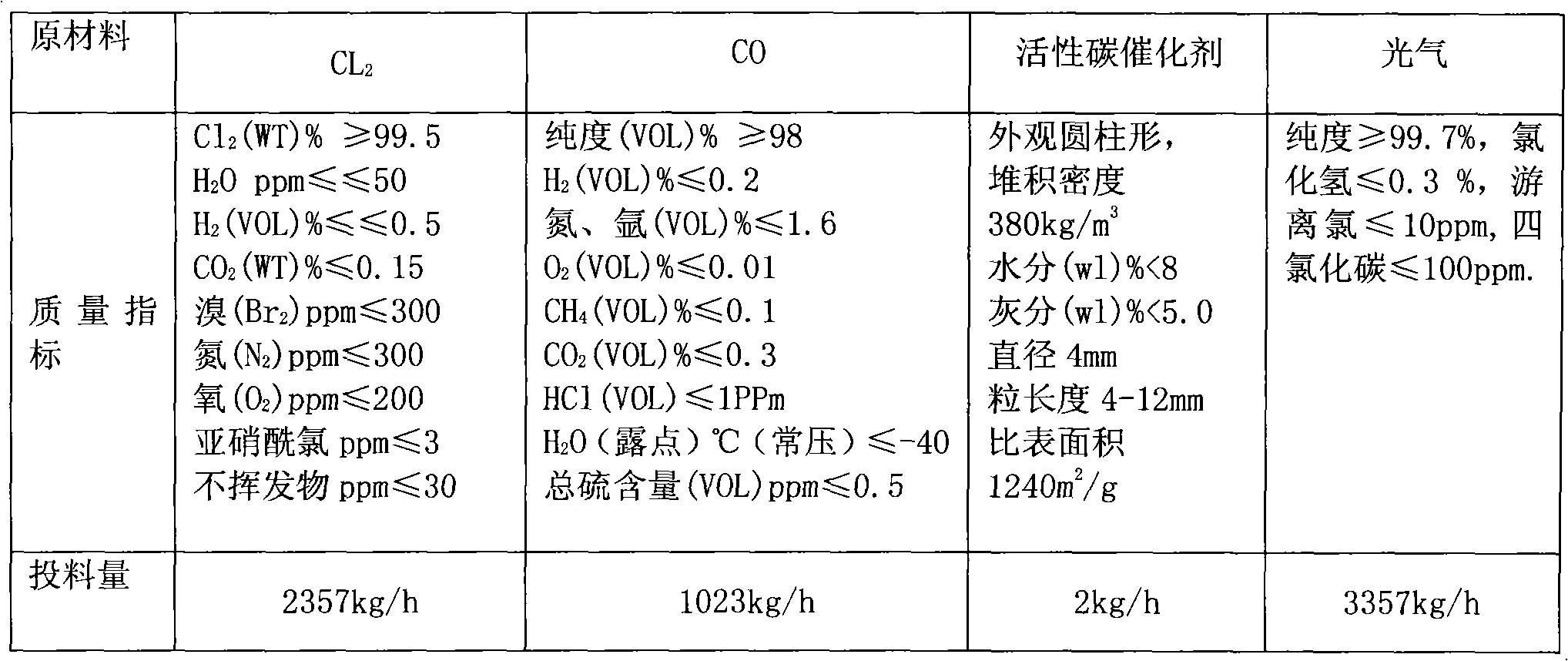

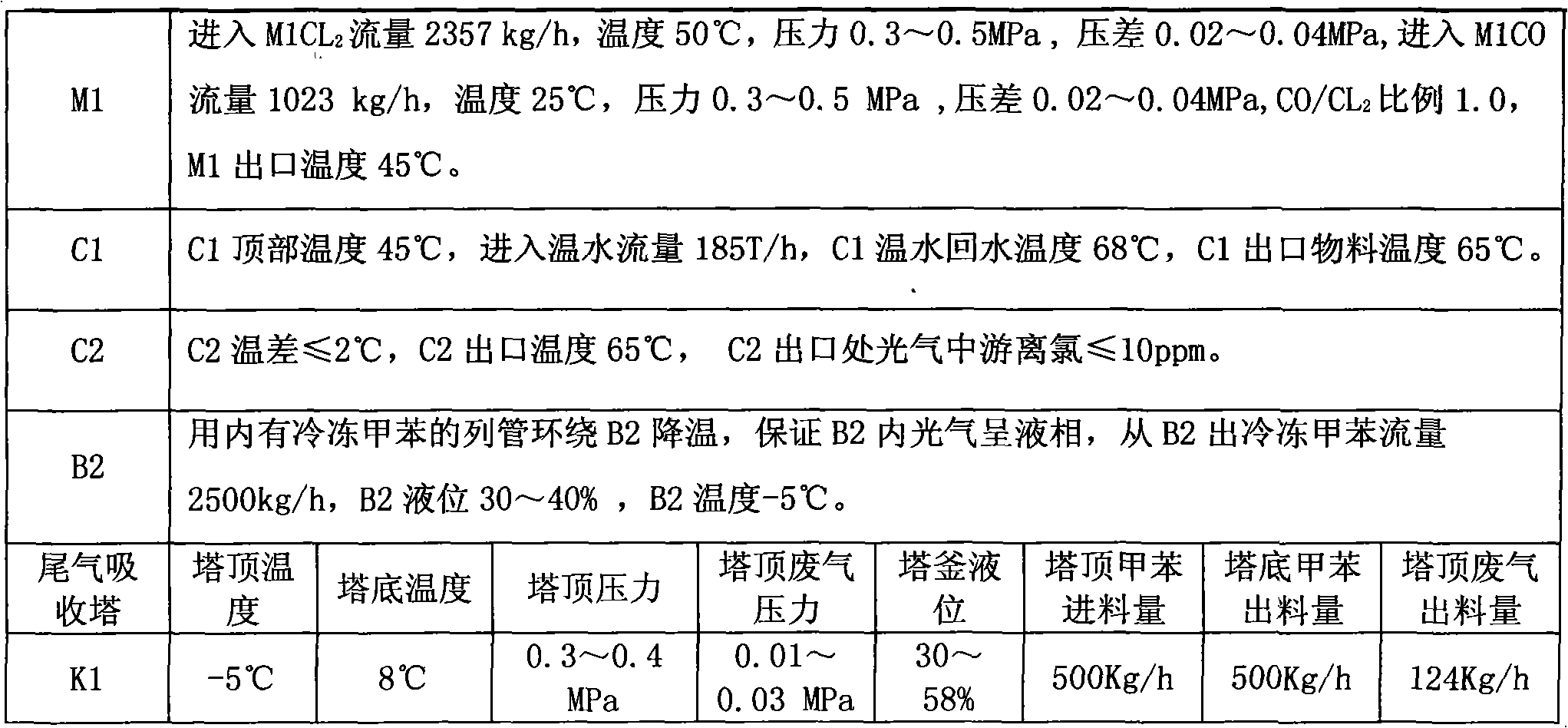

Embodiment 1

[0060] The process conditions of reactor and tower are controlled in the following table:

[0061]

[0062]

Embodiment 2

[0064] The process conditions of reactor and tower are controlled in the following table:

[0065]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

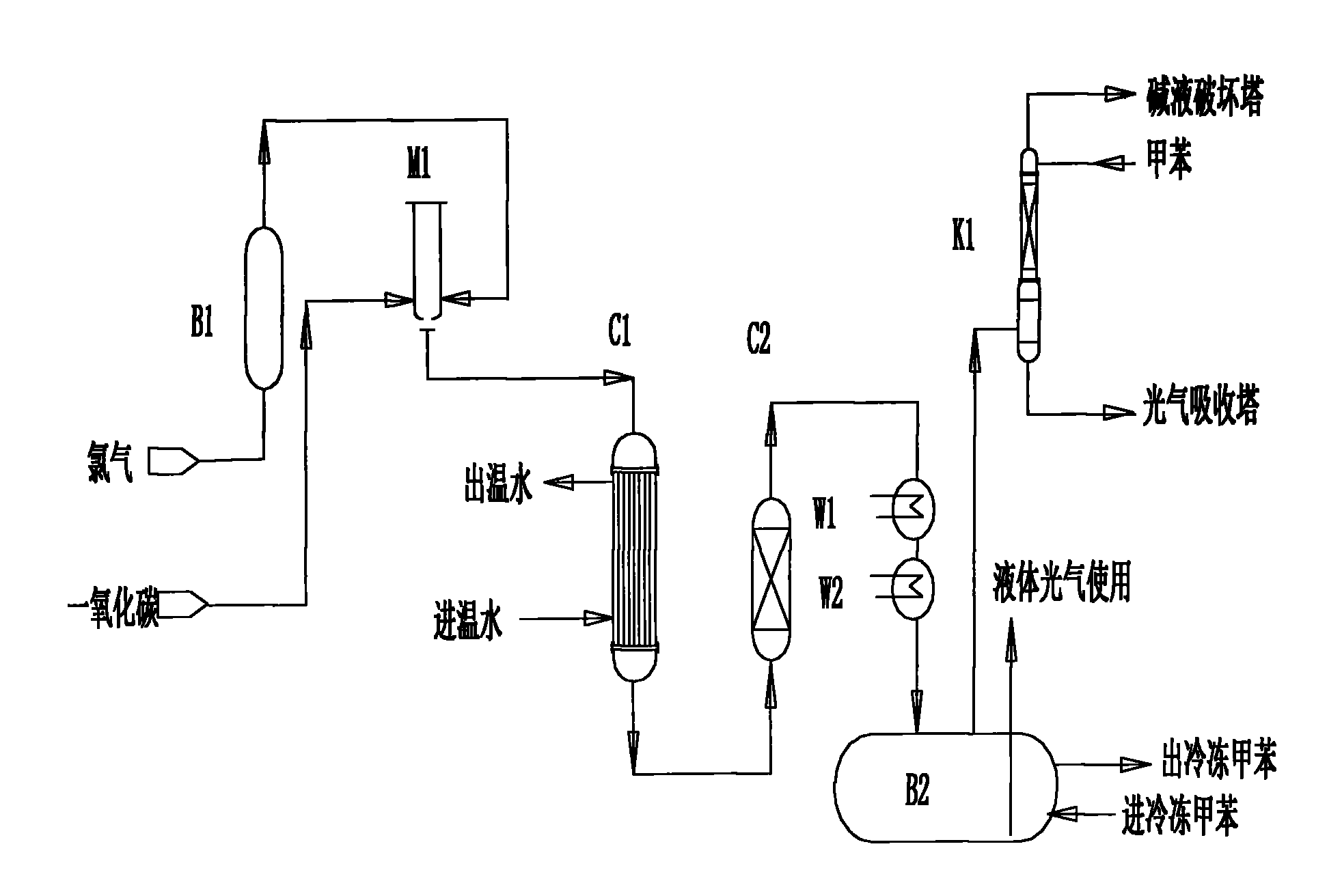

The invention relates to a method for producing phosgene through the reaction of chlorine and carbon monoxide, and in particular to a method that chlorine and carbon monoxide are used to perform an exothermic reaction in a tube reactor in the presence of an activated carbon catalyst and generate phosgene. In the method provided by the invention, after chlorine is mixed with excess carbon monoxidein a mixer M1, then the mixture enters a tubular reactor C1 to react under the action of the activated carbon catalyst and generate phosgene and then passes through a protection reactor C2 to ensure that chlorine reacts completely; and the heat generated by the reaction is led out by a 60 DEG C cooling water system in closed cycle, the generated gaseous phosgene is cooled through W1 condensation and W2 condensation and enters a phosgene gas-liquid separation tank B2, the un-condensed gas enters an exhaust gas absorber K1, and -5 DEG C toluene is used to absorb and recycle phosgene in tail gas.

Description

technical field [0001] The invention relates to a method for producing phosgene by reaction of chlorine gas and carbon monoxide, in particular to a method for producing phosgene by exothermic reaction of chlorine gas and carbon monoxide in a shell and tube reactor in the presence of an active carbon catalyst. Among them, chlorine gas and excess carbon monoxide are mixed in the mixer M1, enter the tubular reactor C1, and react to generate phosgene under the action of an activated carbon catalyst, and then protect the reactor C2 to ensure that the chlorine gas reacts completely; the heat generated by the reaction is provided by a closed circuit The circulating 60°C cooling water system is exported, and the gaseous phosgene generated is condensed and cooled in two stages of W1 and W2, and then enters the phosgene gas-liquid separation tank B2, and the uncondensed gas enters the tail gas absorption tower K1. Absorb the phosgene contained in the exhaust gas and recycle it. Backgr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01B31/28C01B32/80

Inventor 强光明王立新张伟罗代晏耿天奇

Owner 甘肃银光聚银化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com