Protein polypeptide powder, preparation and application thereof

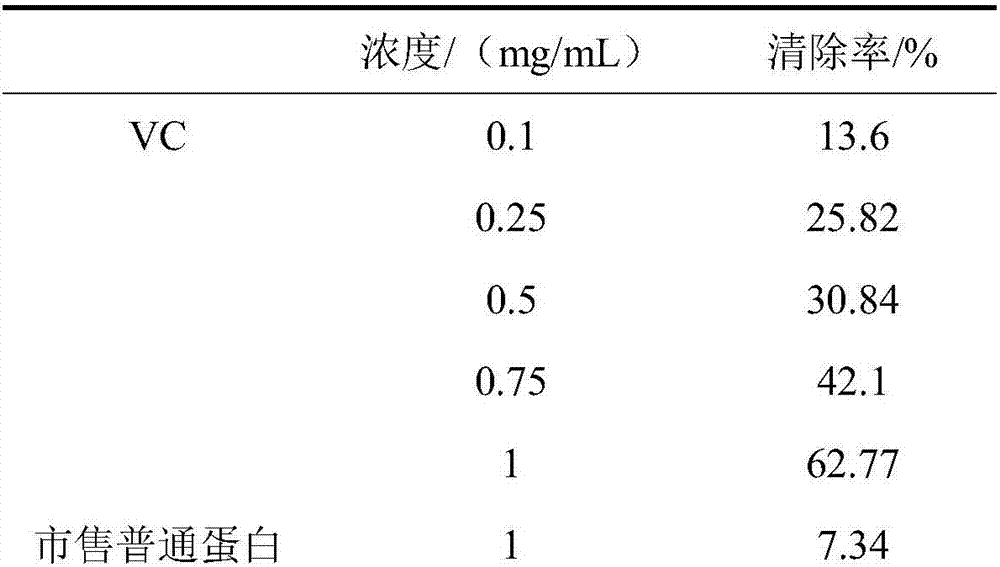

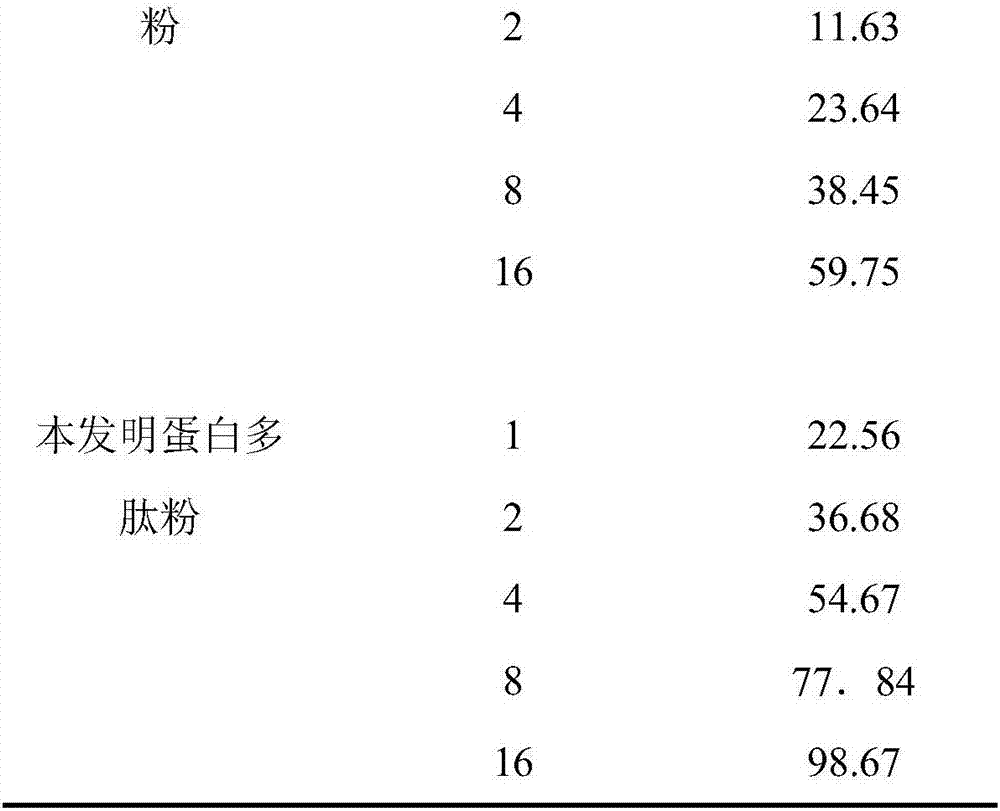

A technology of protein powder and polypeptide powder, which is applied in the fields of application, food ingredients as antioxidants, and food ingredients as taste improvers, etc. It can solve problems such as affecting protein digestion and absorption, increasing the body's digestive burden, and poor body metabolism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] The preparation of embodiment 1 broccoli seed bud powder

[0099] Clean the broccoli seeds ultrasonically at a power of 200W, a frequency of 25KHz, and a room temperature of 25°C for 2.5 minutes, then soak them in clean water at a room temperature of 25°C for 2.5 hours; perform low-frequency and high-voltage pulses on the soaked broccoli seeds, output frequency: 10Hz, and the field of the pulsed electric field Strength: 110kV / m, pulse width 45ms, processing time 1h; broccoli seeds after low-frequency high-voltage pulse treatment are subjected to high-voltage electrostatic treatment, pulse electric field strength: 100kV / m, field strength direction vertically downward, processing time 1h ; Submerge the broccoli seeds treated with high-voltage electrostatics in clear water for 1 hour, place the soaked broccoli seeds in a constant humidity incubator covered with filter paper at a temperature of 30°C, and irradiate with red LED light for 2 hours. 15W, by adjusting the height...

Embodiment 2

[0101] The preparation method of embodiment 2 broccoli leaves mixed powder

[0102] The broccoli leaf mixed powder is composed of a broccoli leaf one-stage extract and a broccoli two-stage extract according to a mass ratio of 5:2; the preparation method of the broccoli leaf mixed powder comprises the following steps:

[0103] Preparation of Broccoli Leaf Phase One Extract:

[0104] (1) Put the broccoli leaves in an ultrasonic cleaning machine with a power of 300W, a frequency of 25KHz, and a room temperature of 20-30°C for 3-5 minutes, rinse and drain, and wash the broccoli leaves according to the mass ratio of material to liquid: 0.6-1:1 Add tap water to the mixture, and pulverize it to obtain broccoli leaf slurry, and filter it with 3-6 layers of filter cloth to obtain broccoli leaf filtrate; add yeast fermentation liquid to the broccoli leaf filtrate, and the broccoli leaf filtrate and yeast The volume ratio of the fermentation broth is 1:2. After stirring and standing sti...

Embodiment 3

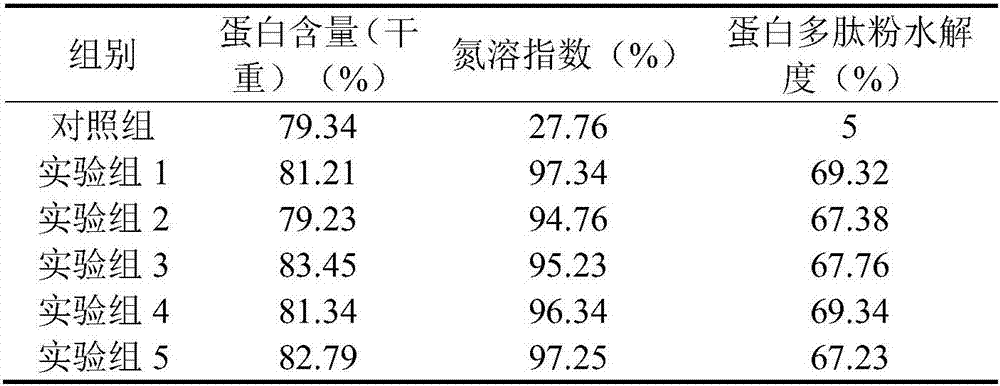

[0110] The preparation method of embodiment 3 broccoli root protein powder

[0111] Cut broccoli root into 0.5cm 3 The cube is subjected to ultra-high pressure treatment, pressurization method: pressurization speed 100MPa / min, temperature in the pressure box 25°C, pressurization medium is distilled water; under the pressure of 260MPa, keep the pressure for 3min, and wait for the end of the pressurization, within 15s Instantaneous pressure release;

[0112] Freeze-dry the broccoli root treated with ultra-high pressure, and ultrafinely pulverize it to obtain a first-stage micropowder;

[0113] The one-stage micropowder was dissolved in distilled water at a material-to-liquid ratio of 1:13, and the mixed solution was subjected to pulse electric field treatment with a pulse width of 5 μs, a pulse field strength of 30 kV / cm, a sample flow rate of 40 mL / min, and a pulse time of 400 μs. After the electric field treatment, the mixed solution was centrifuged at 8000rpm for 25min to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com