Measuring apparatus and method for obtaining apparent viscosity physical property of low-temperature thick liquid through combination with density measurement

A technology of density measurement and measurement device, applied in measurement device, specific gravity measurement, flow characteristics and other directions, can solve the problem of difficulty in accurate measurement, and achieve the situation of simple manufacturing process, comprehensive measurement results, and lack of improved viscosity data. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

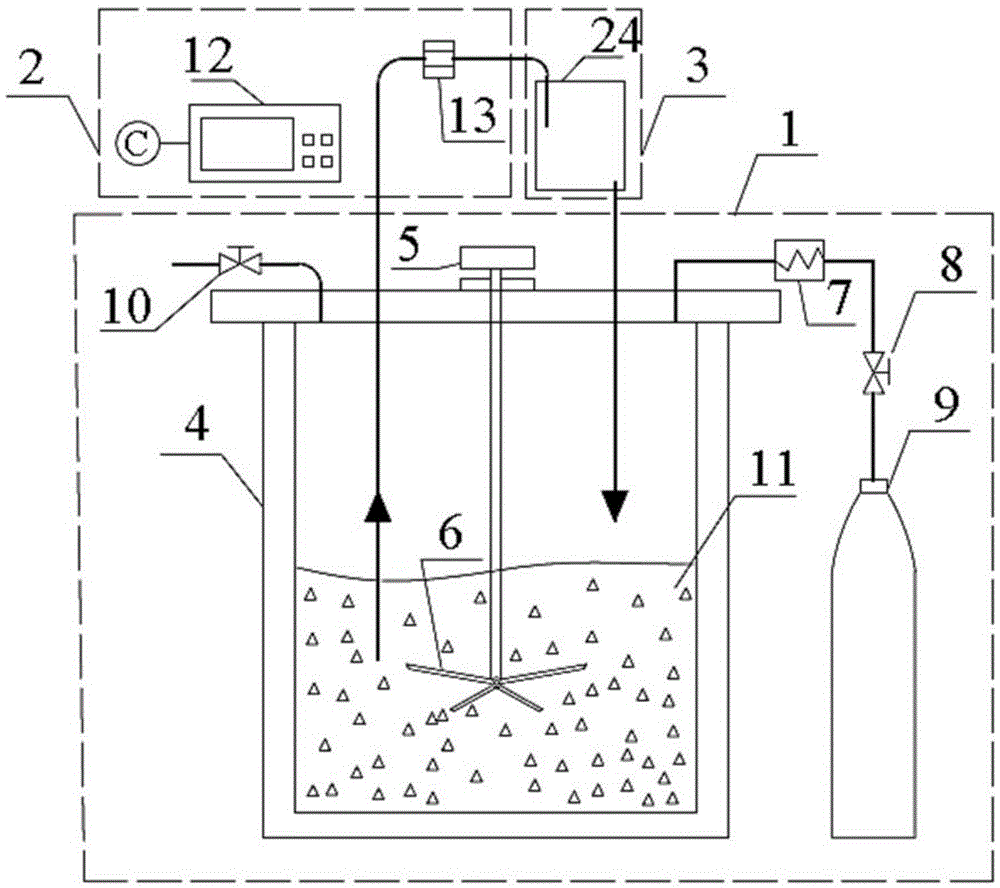

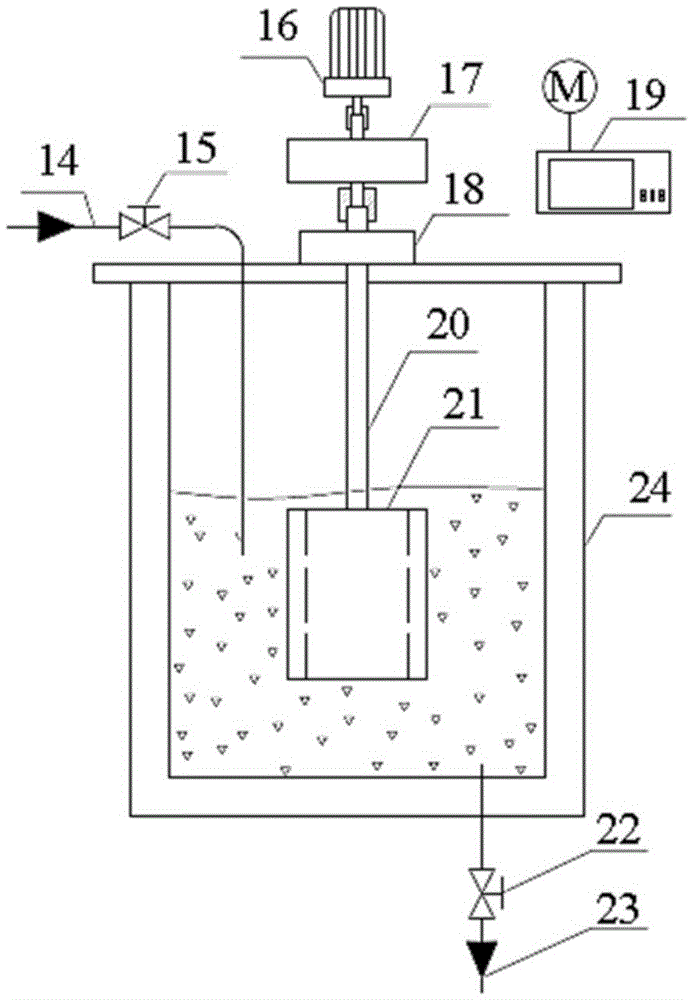

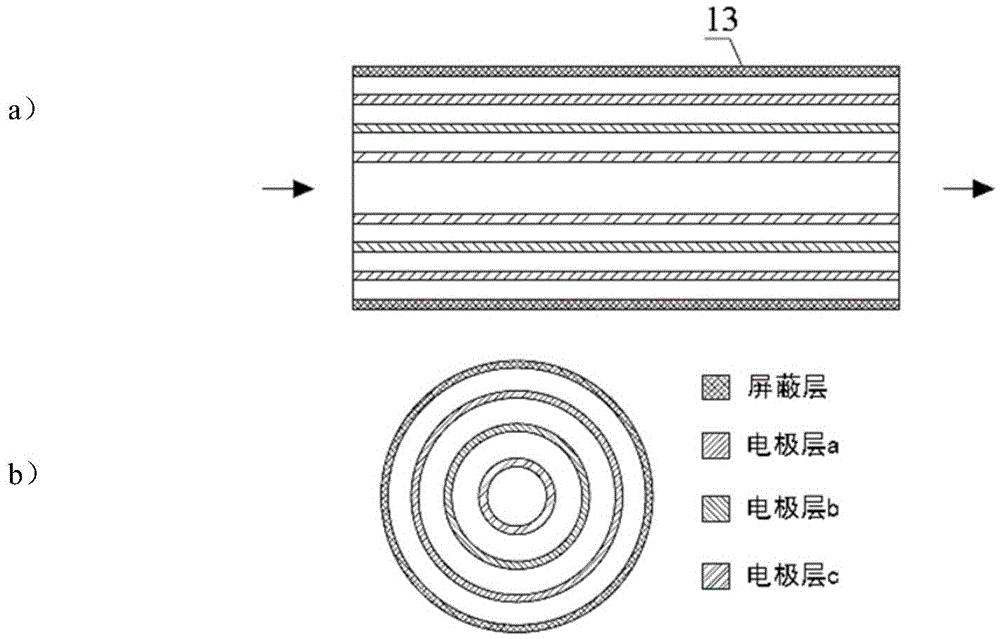

[0027] The concept, structure and working principle of the system of the present invention will be further elaborated below with reference to the accompanying drawings and taking nitrogen slurry as an example, so as to fully understand the purpose and characteristics of the present invention.

[0028] Such as Figure 1-2 As shown, the measuring device for obtaining the apparent viscosity properties of low-temperature slurry in combination with density measurement includes a low-temperature slurry supply unit 1 , a low-temperature slurry density measurement unit 2 and a low-temperature slurry viscosity measurement unit 3 . The low-temperature slurry supply unit 1 is connected to the low-temperature slurry density measurement unit 2 and the low-temperature slurry viscosity measurement unit 3 sequentially through pipelines, so that the nitrogen slurry flows through the two units in sequence and measures the density and viscosity of the slurry respectively.

[0029] The main body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com