Mixed containing cavity heat dissipation gas wave refrigerating machine

A gas-wave refrigerator and heat-dissipating technology, which is applied in the field of pressure gas expansion refrigeration, can solve the problems of large average proportion of jet mixing, unrecoverable heat, and fluctuating efficiency, so as to reduce the amount of mutual mixing and easy recovery. The effect of improving the utilization and cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A typical implementation of the common-cavity heat-dissipating gas wave refrigerator of the present invention will be described below, but it is not limited to this one.

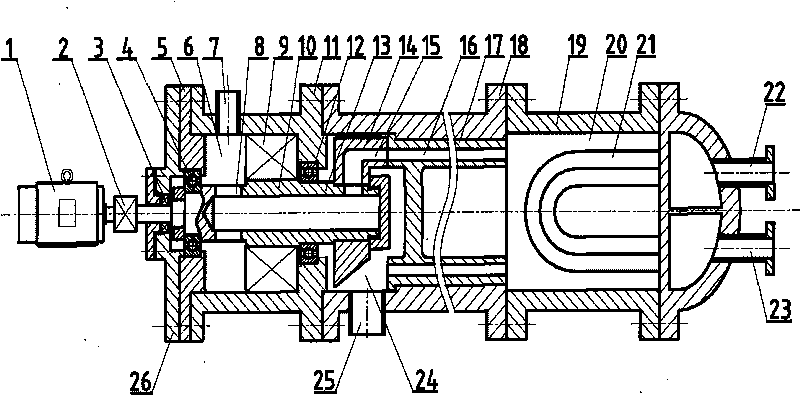

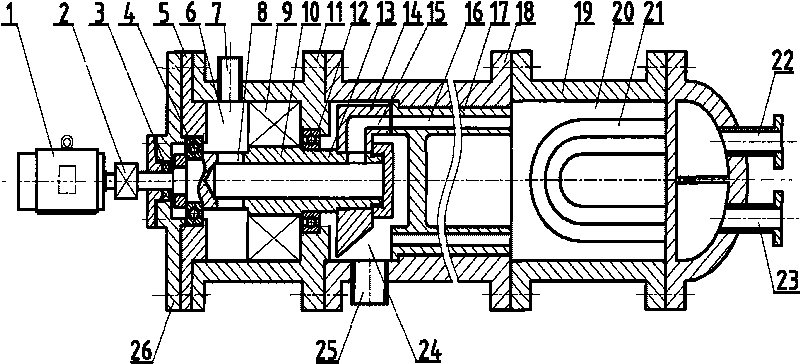

[0026] The common-cavity heat-dissipating gas wave refrigerator mainly consists of an air intake cavity 6, an air intake pipe 7, an internal rotary seal 9, a main shaft 10, a body 11, a rotating jet distributor 14, a short receiving tube 16, a receiving tube cylinder 17, Composed of a common chamber 20, a heat exchange unit 21, a cold air outlet cavity 24, and a cold air outlet pipe 25, the jet flow distributor 14 is rotated so that the jets are sequentially aligned to the nozzles at the beginning of each short receiving pipe 16 and enter the pipe to cool and then return to discharge. It is characterized in that: the non-jet inlet end, that is, the end, of the short receiving tubes 16 arranged in a circle is also open, and the end opening communicates with the common accommodation cavity 20, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com