Sliding bearings for construction

A technology for sliding bearings, construction, applied in the direction of construction, shafts and bearings, bearing components, etc., which can solve the problems of polyamide viscoelastic loss, unsuitability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

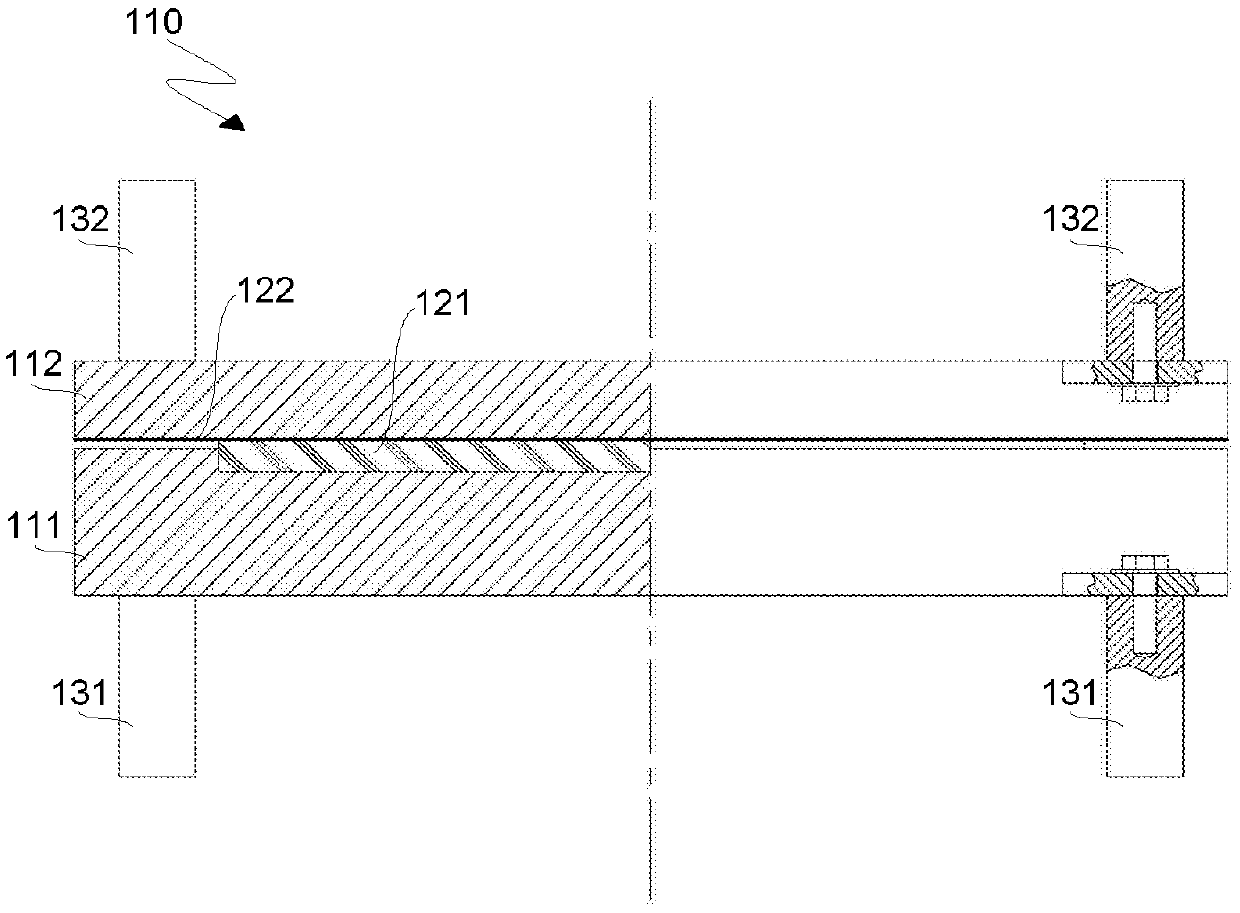

[0045] refer to figure 1 , the sliding bearing according to the invention is generally indicated by reference numeral 110 . The slide bearing 110 comprises a first part 111 and a second part 112 operatively connected to each other and configured to bear longitudinal loads.

[0046] The first part 111 is intended to be connected to a supporting structure, such as a mass bridge or the foundation of a building or an industrial plant, and the second part is configured to be connected to an element intended to be placed on said supporting structure, such as a bridge deck or a building or industrial plant. Beams of an industrial plant. In the embodiment shown, the connection of the bearing parts connected to the support structure to the elements is achieved for example by special feet or posts 131 , 132 intended to fit and fix in holes formed on these parts.

[0047] Bearing 110 also includes at least one pair of sliding surfaces disposed between the first and second components to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com