Combined Small Hole Impeller Composite Muffler

A composite muffler and combined technology, applied in the direction of sound-producing equipment, instruments, etc., can solve the problems of hearing loss, reduced work quality, unresponsiveness, etc., and achieve the effect of widening the noise frequency band and improving the noise reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

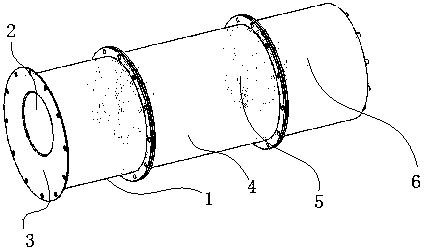

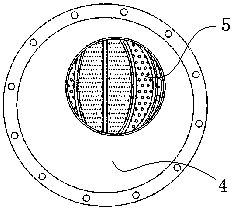

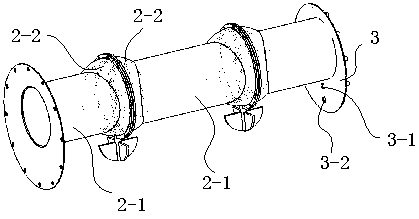

[0025] Such as figure 1 and figure 2 As shown, a compound muffler with a combined small hole impeller includes a casing 1 arranged in parallel and an inner pipe 2 inside the casing 1; both ends of the inner pipe 2 are sealed and connected to the casing 1 through a sealing head 3, A water injection hole 3-1 and an exhaust hole 3-2 are opened on the sealing head 3 to communicate with the outside world and the sealed cavity 4 formed between the inner tube 2 and the casing 1; the inner tube 2 is equipped with an impeller 5 .

[0026] combine image 3 , Figure 5 to Figure 7 As shown, the inner tube 2 is formed by connecting multiple sections of internal cylinders 2-1; in this embodiment, three sections of internal cylinders 2-1 are taken as an example, and the adjacent ends of the internal cylinders 2-1 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com