Motor cover and handheld dust collector

A technology of motor cover and motor housing, which is applied in the direction of vacuum cleaners, suction filters, suction nozzles, etc., which can solve the problems of large noise of airflow generators and affect user experience, so as to increase noise reflection, increase dissipation, and reduce noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

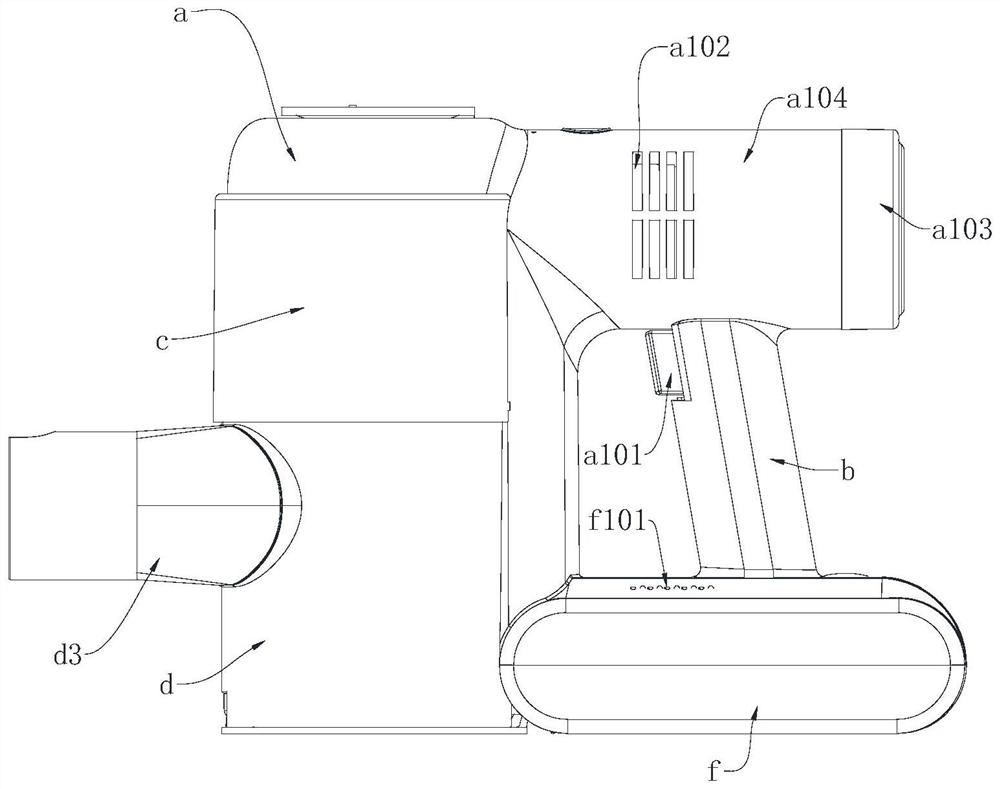

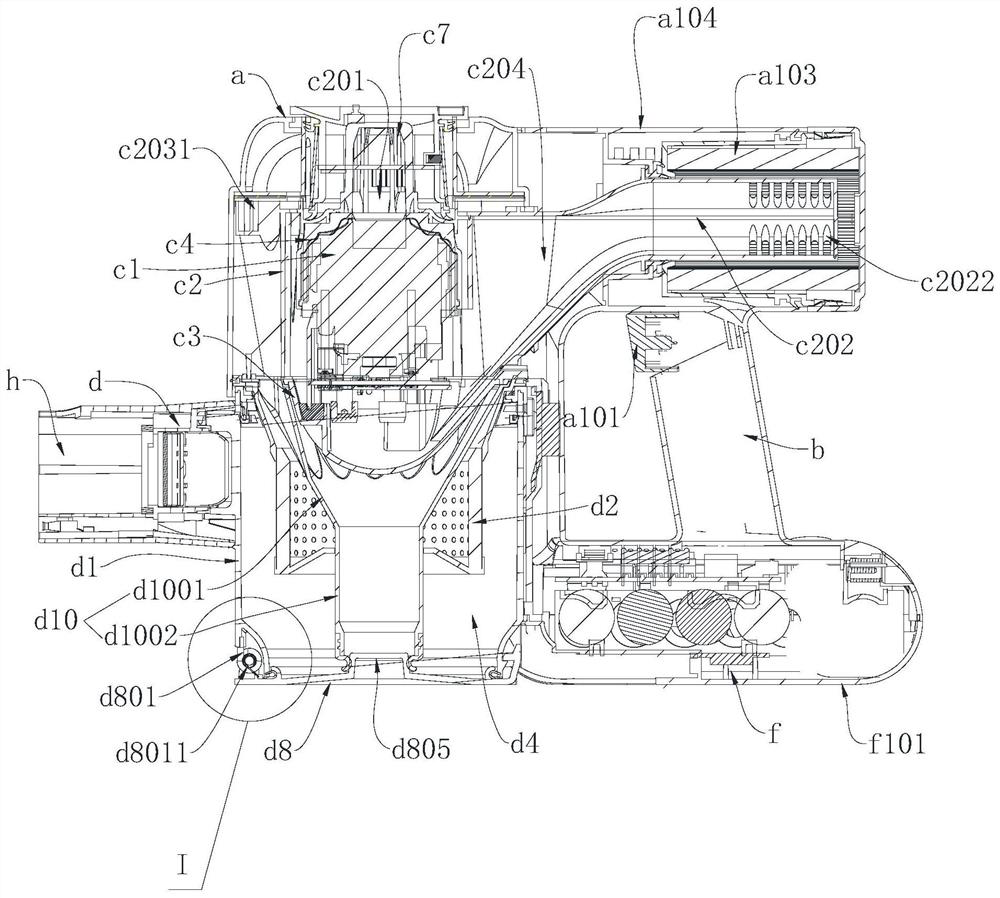

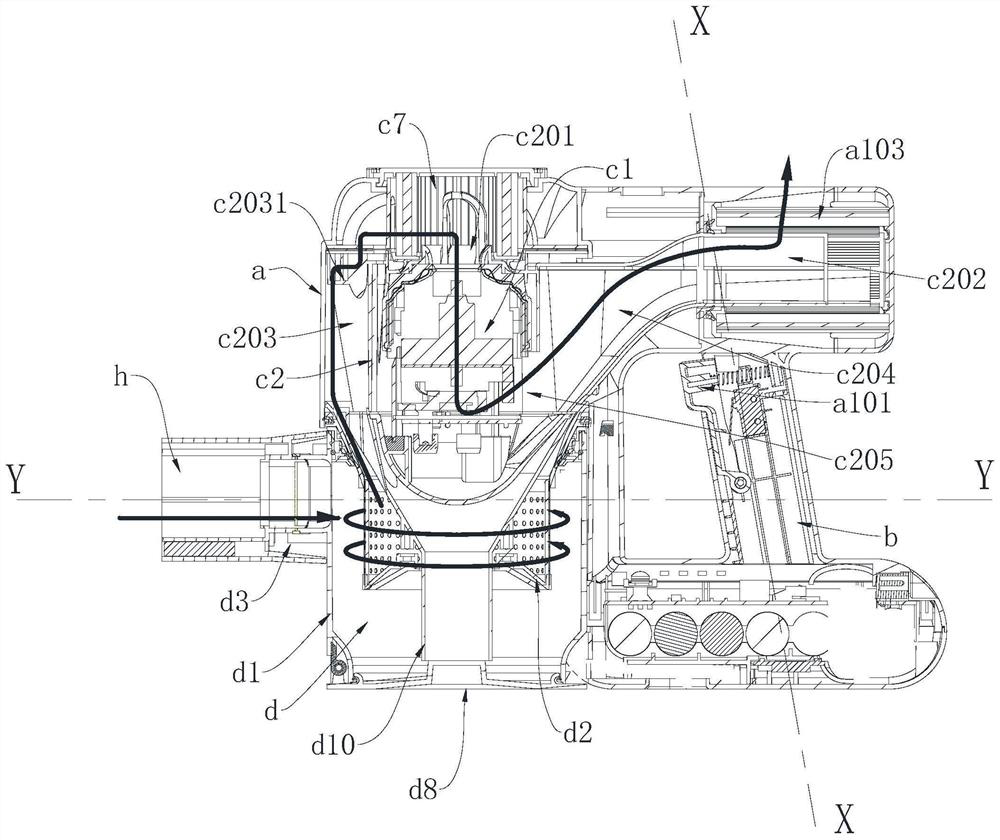

[0073] This embodiment provides a hand-held vacuum cleaner, such as figure 1 - image 3 As shown, it includes: a main body casing a; an airflow generator, which is arranged in the main body casing a, and the airflow generator is used to form a negative pressure in the main body casing a, and the airflow generator and the main casing A channel for air flow is formed between the bodies a; a dust separator is arranged in the main body casing a, and the dust separator is located between the airflow generator and the main body casing a, and the dust separator Set around the air flow generator. When the dust separator surrounds the airflow generator, the height of the airflow generator and the height of the dust separator partially overlap, so the total height of the dust separator and the airflow generator after assembly is smaller than that of the dust separator and the airflow generator sum of heights. Compared with the separate airflow generator and dust separator in the prio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com