Method and equipment for realizing low-temperature thermal power generation by cryogenic technology

A thermal power generation and low temperature technology, which is applied in the fields of thermal power, environmental protection, power generation, refrigeration, machinery manufacturing and automation, and can solve the problems of stable heat source and limitation of the selection of refrigerants.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

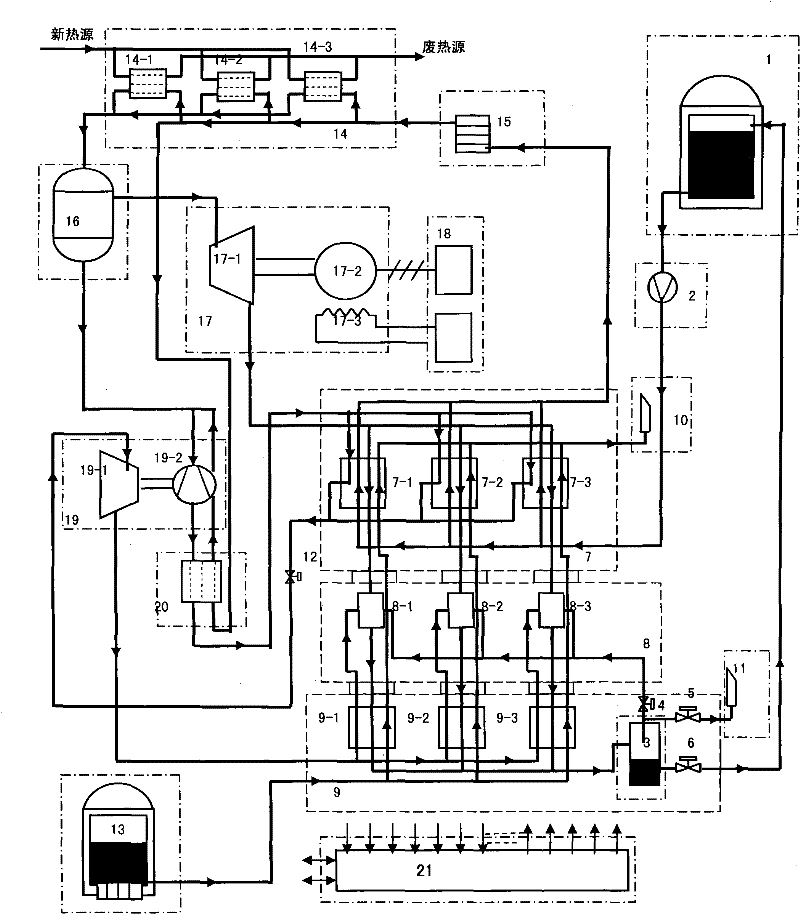

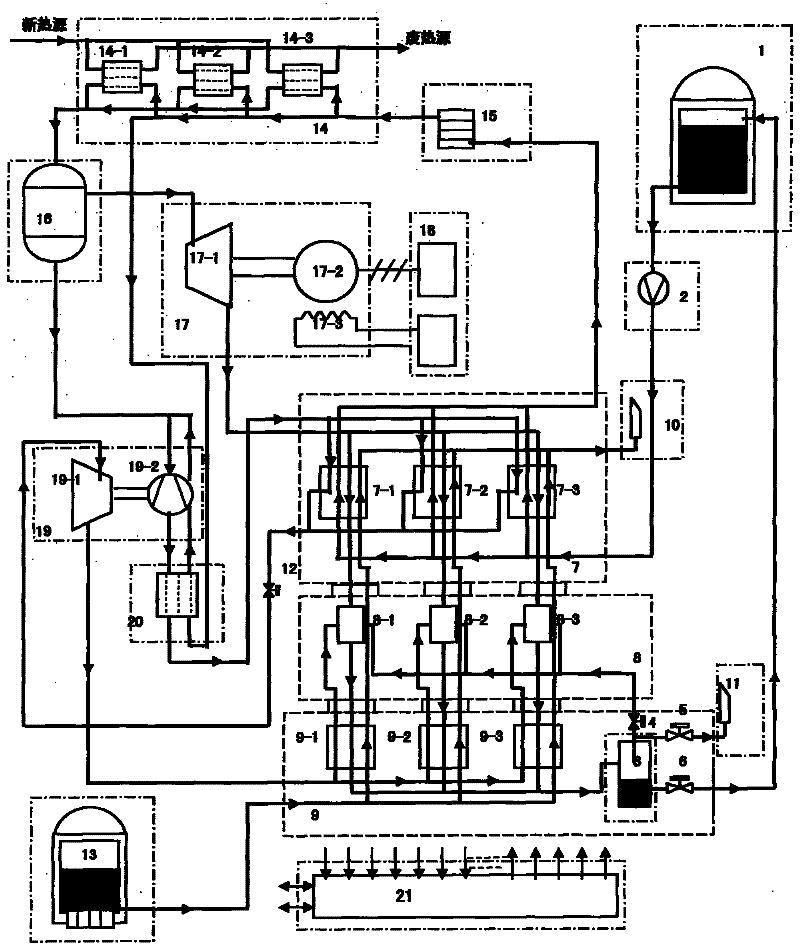

[0030] 1 The implementation will be described below in conjunction with the accompanying drawings:

[0031] The cryogenic liquid pump 2 is pumped out from the vacuum insulation refrigerant storage tank 1, and the refrigerant is increased to a certain pressure (medium and high pressure) and kept stable, and then sent to the plate heat exchanger 7 through the vacuum insulation tube. It exchanges heat with the positive flow air from the turbo expander 17-1, completes the phase change and fully gasifies, enters the air bath heat exchanger 15 at an intercooling temperature slightly lower than the positive flow air, and sends it into the air bath heat exchanger after the temperature rises further. The air-water (or air-gas, gas-vapor) heat exchanger 14 fully exchanges heat with the heat source, and has a certain degree of superheat, and sends it into the buffer tank 16 after approaching the heat source inlet temperature. The gas coming out from the buffer tank is divided into two ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com