Double-thermal-shield negative-pressure low-temperature heat exchanger test device

A negative pressure low temperature, testing device technology, applied in the direction of measuring devices, machine/structural components testing, instruments, etc., can solve the problems of harsh application conditions and complex design of negative pressure heat exchangers, and achieve the goal of improving accuracy and expanding scope. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand and understand the technical solution and the achieved effects of the present invention, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

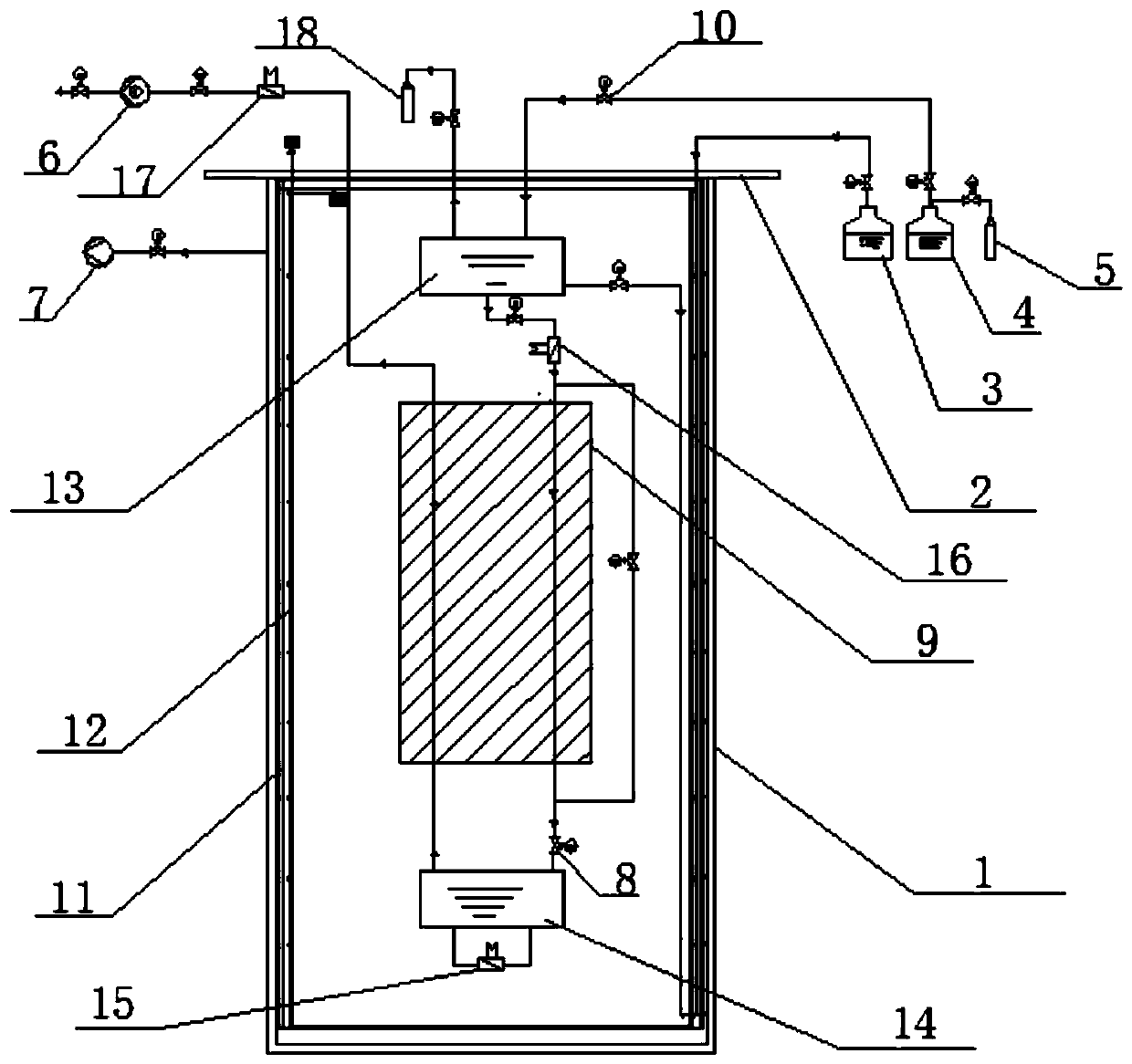

[0017] Such as figure 1 As shown, a kind of negative pressure cryogenic heat exchanger test device with double cold screens according to the present invention, the negative pressure low temperature heat exchanger test device with double cold screens includes a low temperature cold box and external equipment, and the low temperature cold box Including box body (1), upper end cover (2), liquid nitrogen cold shield (11), liquid helium cold shield (12), 4.5K liquid helium tank (13), 1.8K superfluid helium tank (14), tested The heat exchanger (9), the first heater (15), the second heater (16) and the low-temperature pneumatic control valve (8), the upper end cover (2) is fixedly connected to the upper part of the box body (1), and the outer The equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com