Experimental equipment for testing characteristic of liquid helium filter

A characteristic test and filter technology, which is used in measuring devices, machine/structural parts testing, instruments, etc., can solve the problem of not finding liquid helium filter characteristic test device data, etc., so as to reduce the consumption of liquid helium and achieve uniform mixing. , the effect of reducing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

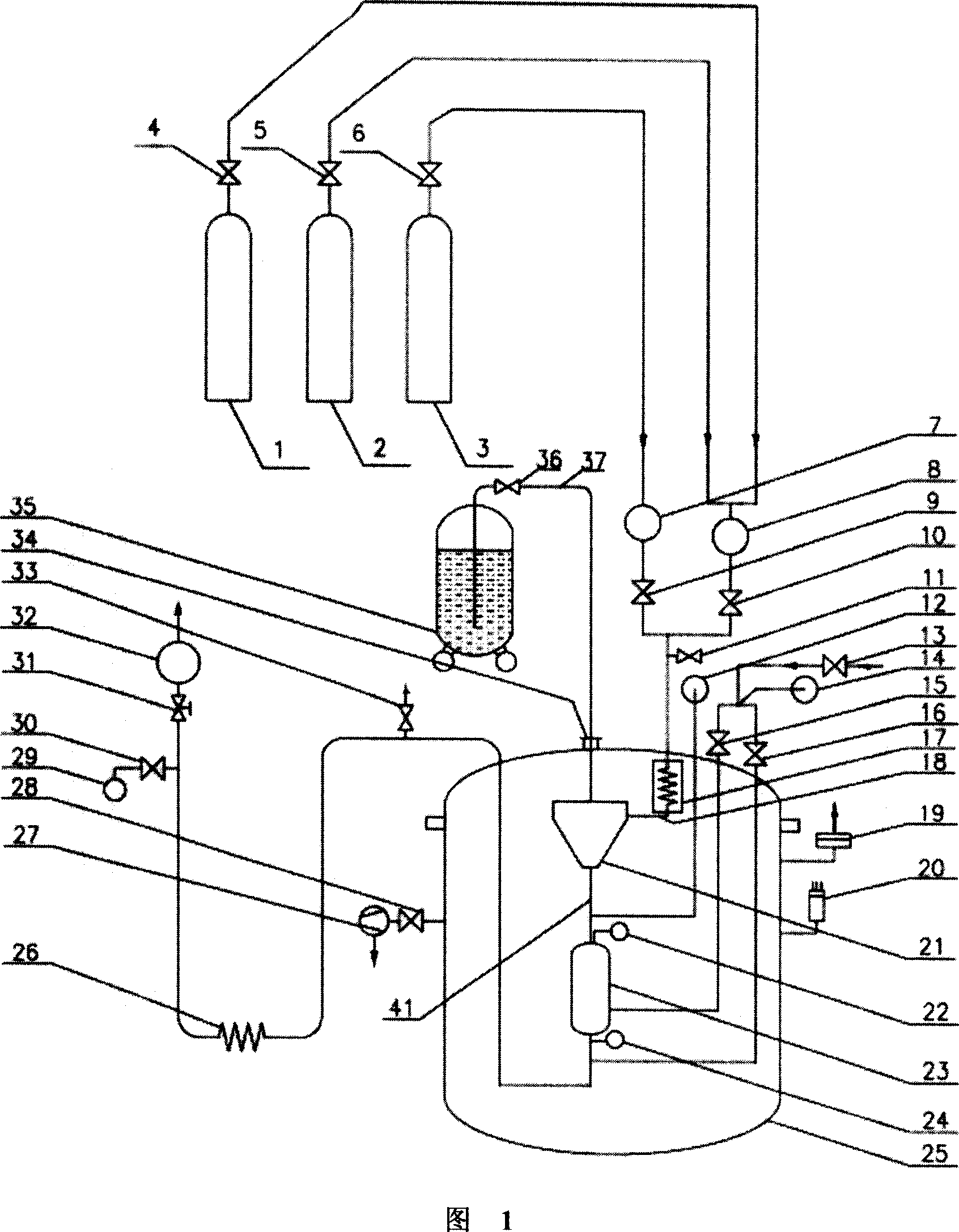

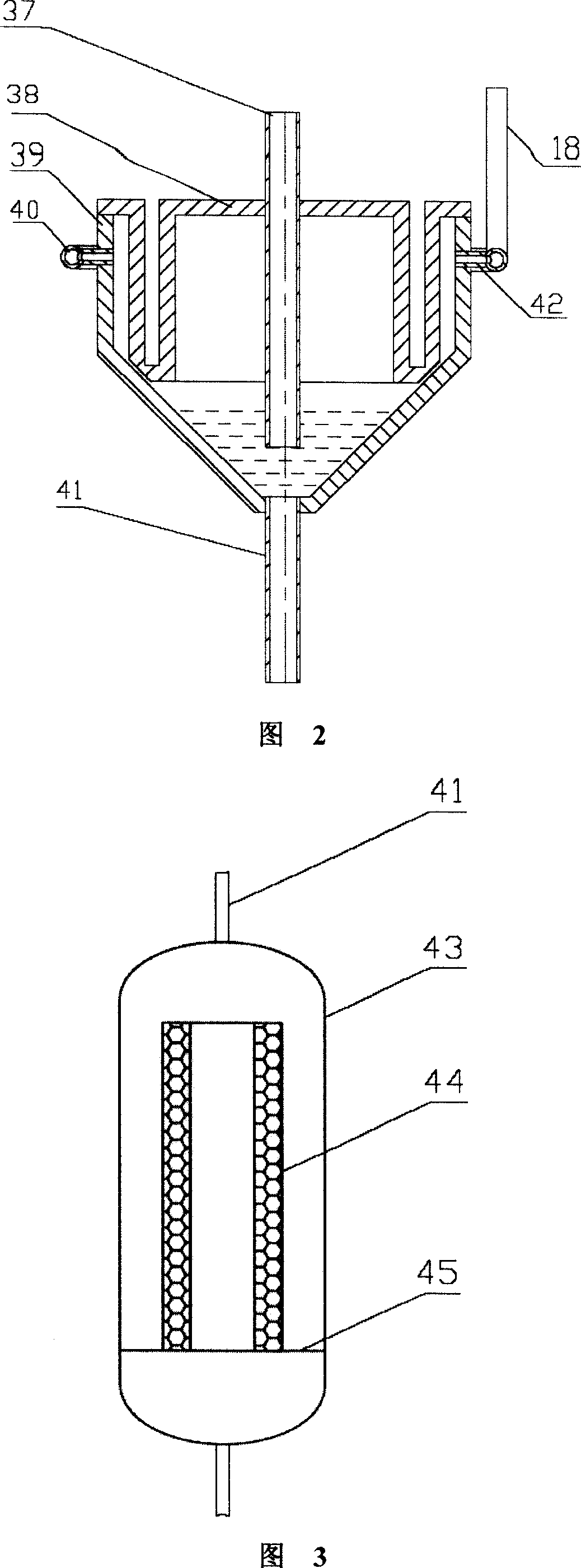

[0017] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0018]As shown in Figure 1, Figure 2 and Figure 3, the present invention comprises an oxygen cylinder 1, a nitrogen cylinder 2, a helium cylinder 3, an oxygen decompression valve 4, a nitrogen decompression valve 5, a helium decompression valve 6, a helium flow rate Meter 7, Nitrogen and Oxygen Flow Meter 8, Helium Filling Valve 9, Nitrogen and Oxygen Filling Valve 10, Air Release Valve 11, A Pressure Sensor 12, Regeneration Helium Inlet Valve 13, B Pressure Sensor 14, A Regeneration Helium intake branch valve 15, B regeneration helium intake branch valve 16, impurity gas precooler 17, doping gas connecting pipe 18, burst disc 19, vacuum gauge 20, gas-liquid mixer 21, A temperature sensor 22. Liquid helium filter 23, B temperature sensor 24, vacuum box 25, heat exchanger 26, vacuum pump 27, vacuum valve 28, gas chromatograph 29, sampling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com