System for improving air quality in an aircraft pressure cabin

A technology for pressure chambers and aircraft, applied in air handling equipment, aircraft parts, weight reduction, etc., can solve problems such as increased bleed air consumption, and achieve the effect of reducing weight, saving costs, and saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

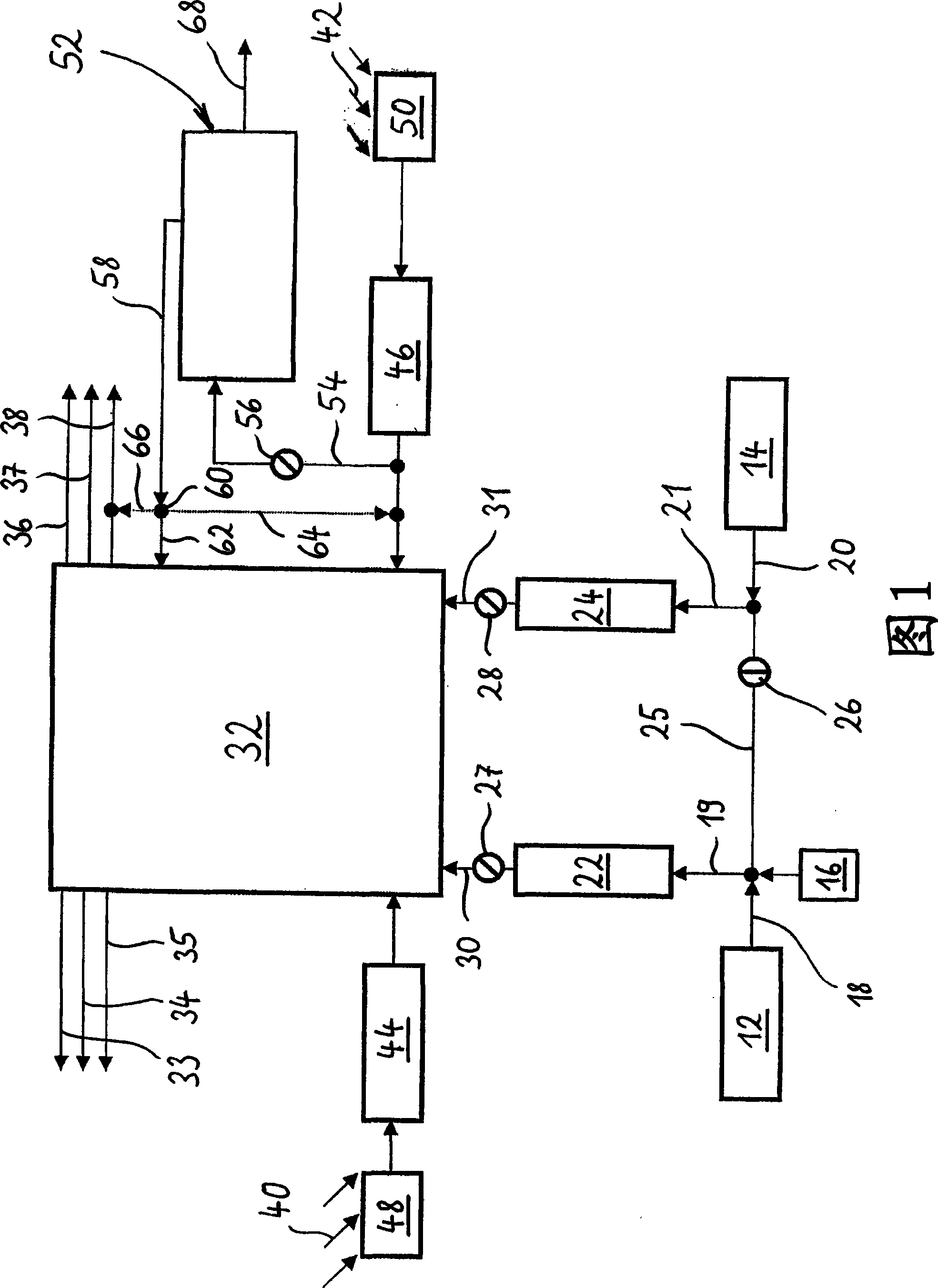

[0021] Fig. 1 shows a first embodiment, which concerns an aircraft with two engines 12, 14 and an auxiliary power unit 16, it being clear that the basic operation of the system does not depend on the precise number of engines or the presence of an auxiliary power unit.

[0022] To pressurize the cabin of the aircraft (not further described), bleed air from the engine 12 and / or the engine 14 and / or the auxiliary power unit 16 is supplied via lines 18, 19 and 20, 21 to two air conditioning units 22, 24 . A connecting line 25 equipped with a shut-off valve 26 is used to simultaneously supply bleed air from the engine 12 and / or auxiliary power unit 16 to both air conditioning units 22, 24, or to supply air from the engine 14 to both Air conditioning units 22,24. With shut-off valve 26 closed, air conditioning unit 22 is supplied with bleed air from engine 12 and / or auxiliary power unit 16 only, while air conditioning unit 24 is supplied with bleed air from engine 14 only.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com