Pressure-sustaining gas assistant injection molding system

An injection molding, constant pressure gas technology, applied in the direction of nitrogen purification/separation, can solve the problems of difficult to achieve stable gas injection and pressure maintenance, difficult to control gas pressure, etc., to reduce product development and production costs, stable gas injection and The effect of maintaining pressure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following examples are further explanations and illustrations of the present invention, and do not constitute any limitation to the present invention.

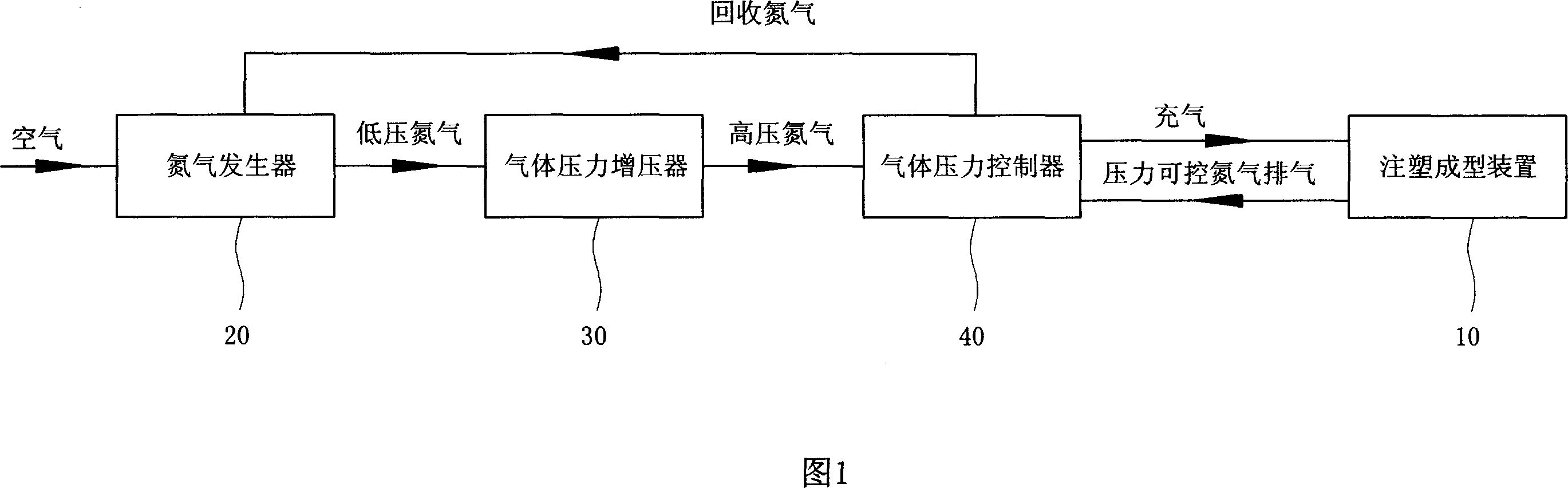

[0032] Referring to FIG. 1 , the constant-pressure gas-assisted injection molding system of the present invention consists of four parts: an injection molding device 10 , a nitrogen generator 20 , a gas pressure booster 30 and a gas pressure controller 40 .

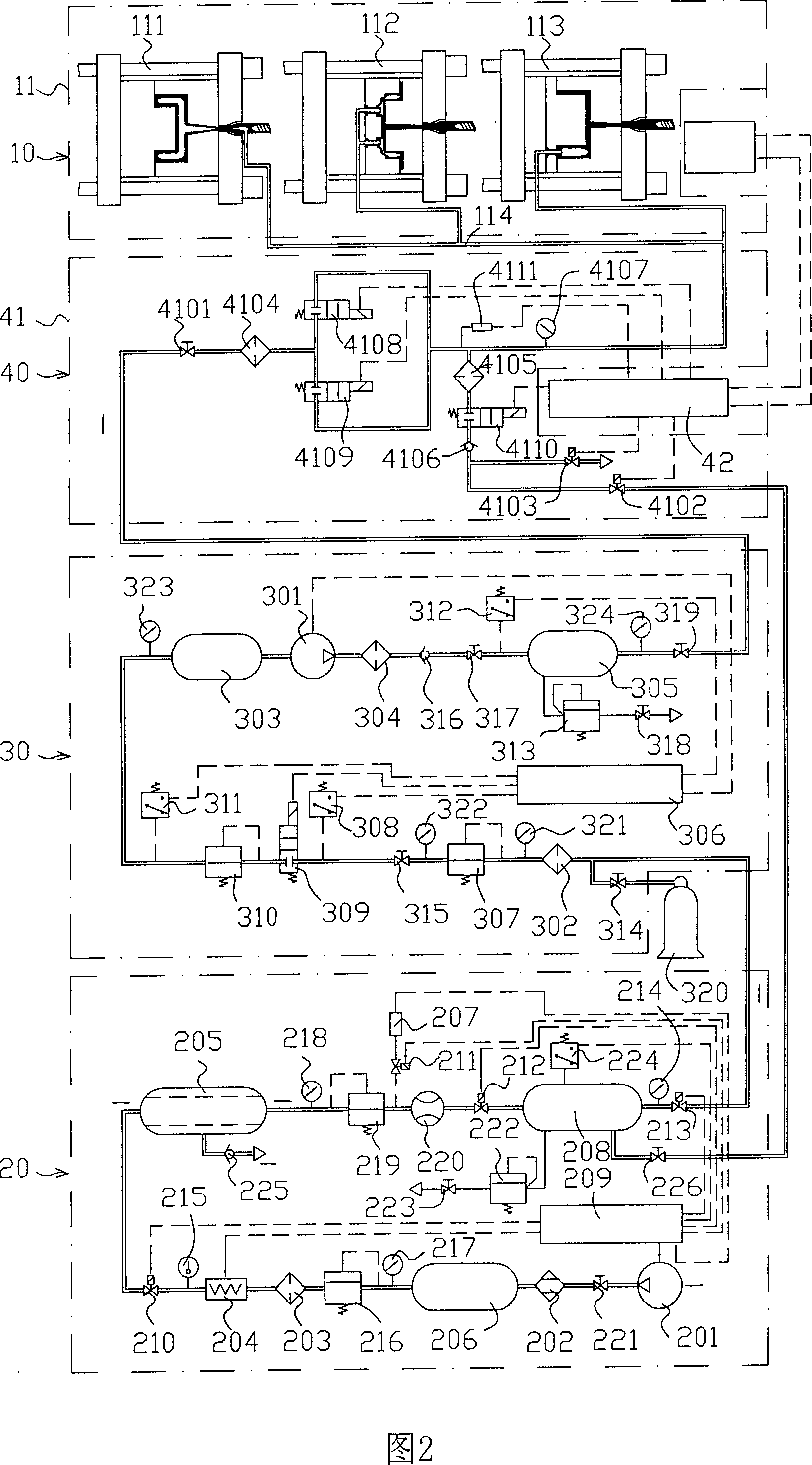

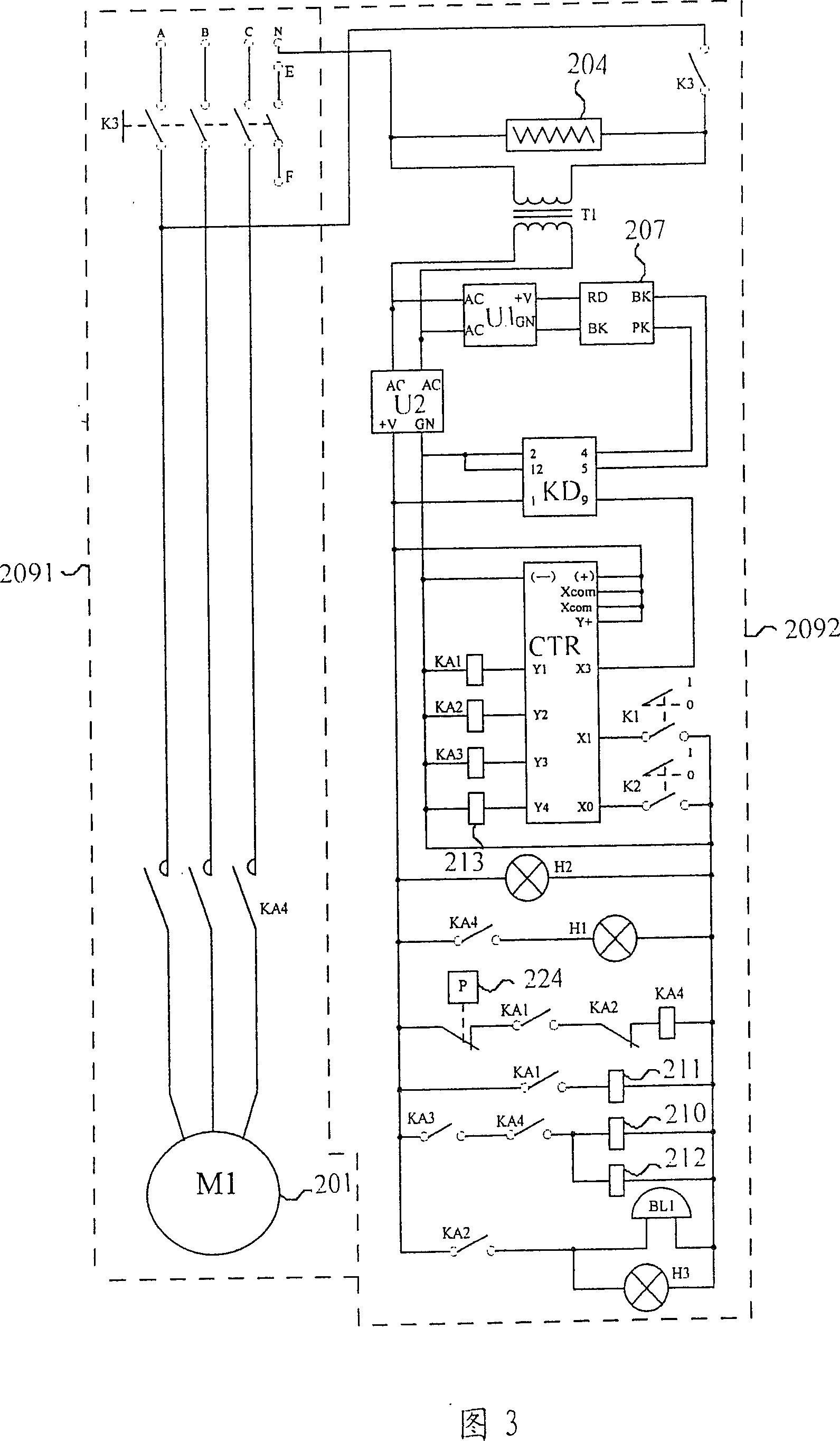

[0033] As shown in Figure 2, the nitrogen generator 20 includes an air compressor 201, a drier 202, a first filter 203, an electronic heater 204, a membrane air separator 205, a compressed air buffer tank 206, an oxygen concentration analysis Instrument 207, low-pressure nitrogen storage gas tank 208 and nitrogen generator controller 209, the above-mentioned dryer is a freeze dryer, and the IDU type freeze dryer of Japan SMC is selected for use. The first filter 203 is a sintered metal filter, and the FGD filter of Japan SMC is selected. The electronic heater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com