Aramid fiber high-temperature forming machine

A sizing machine and high-temperature technology, which is applied in the direction of heat treatment of textiles, papermaking, and artificial filaments, etc., can solve the problems of large temperature difference, failure to reach the aramid sizing process, and non-dispersion, so as to prevent oxidation, save energy and power, and ensure safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

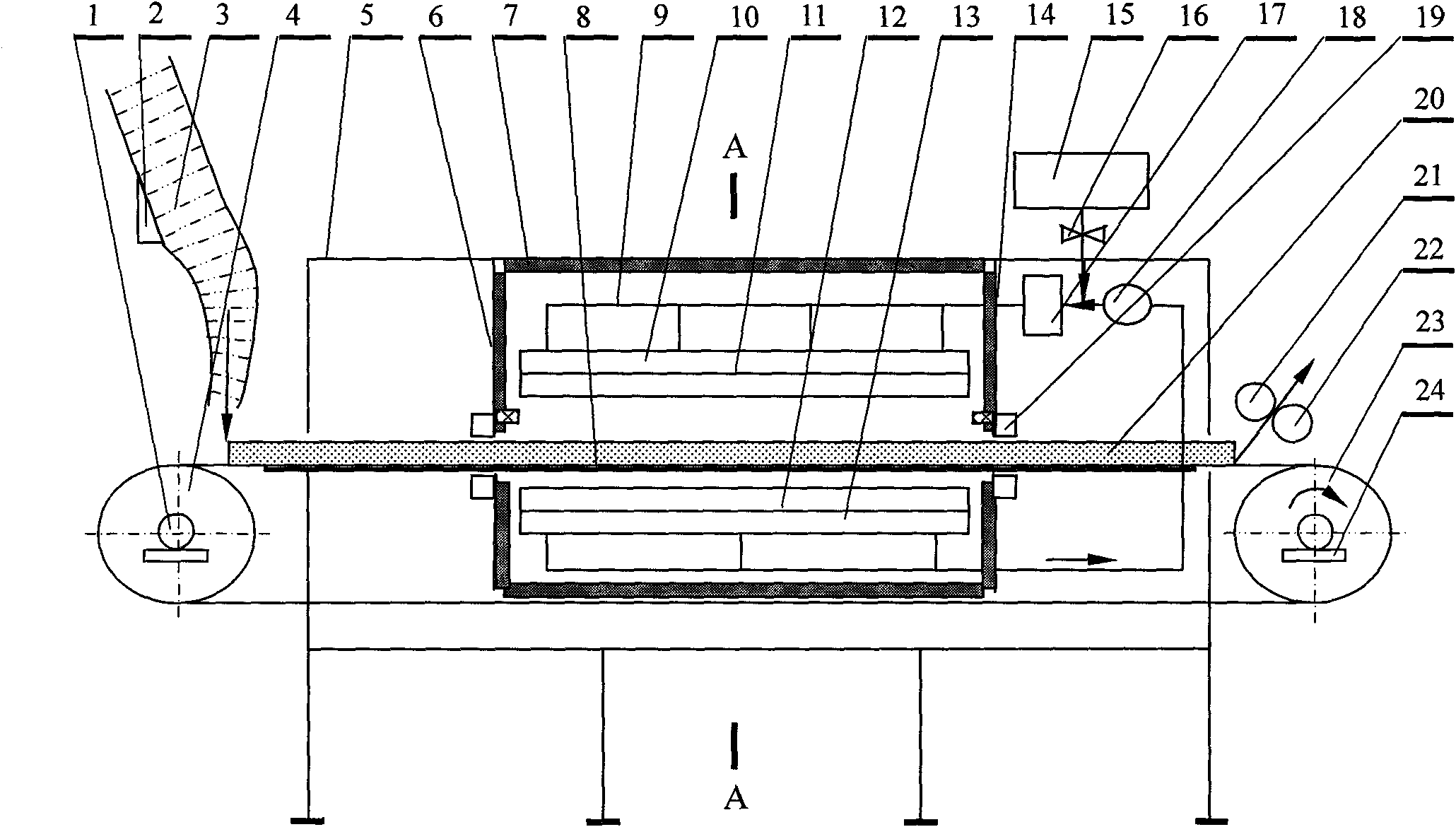

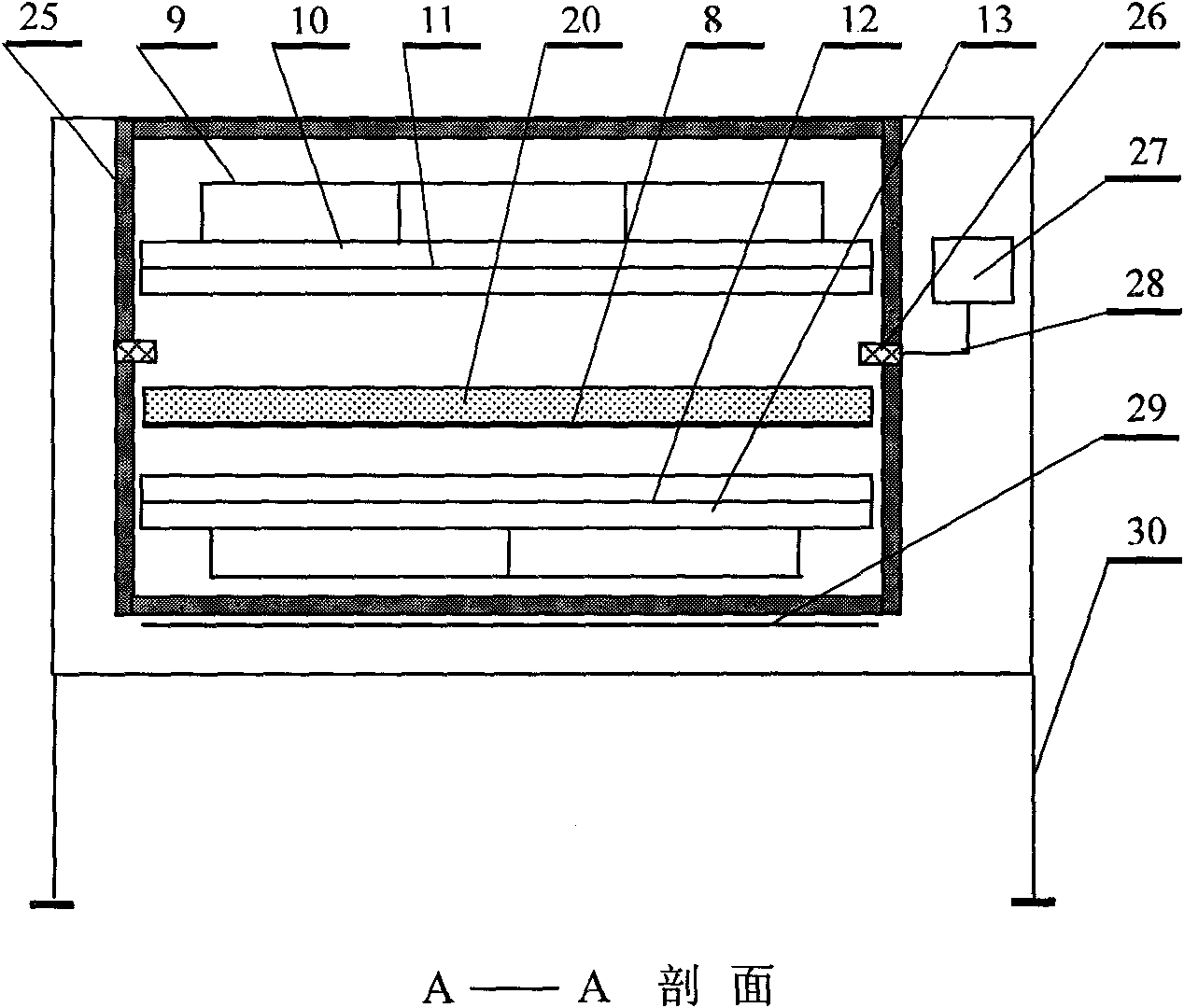

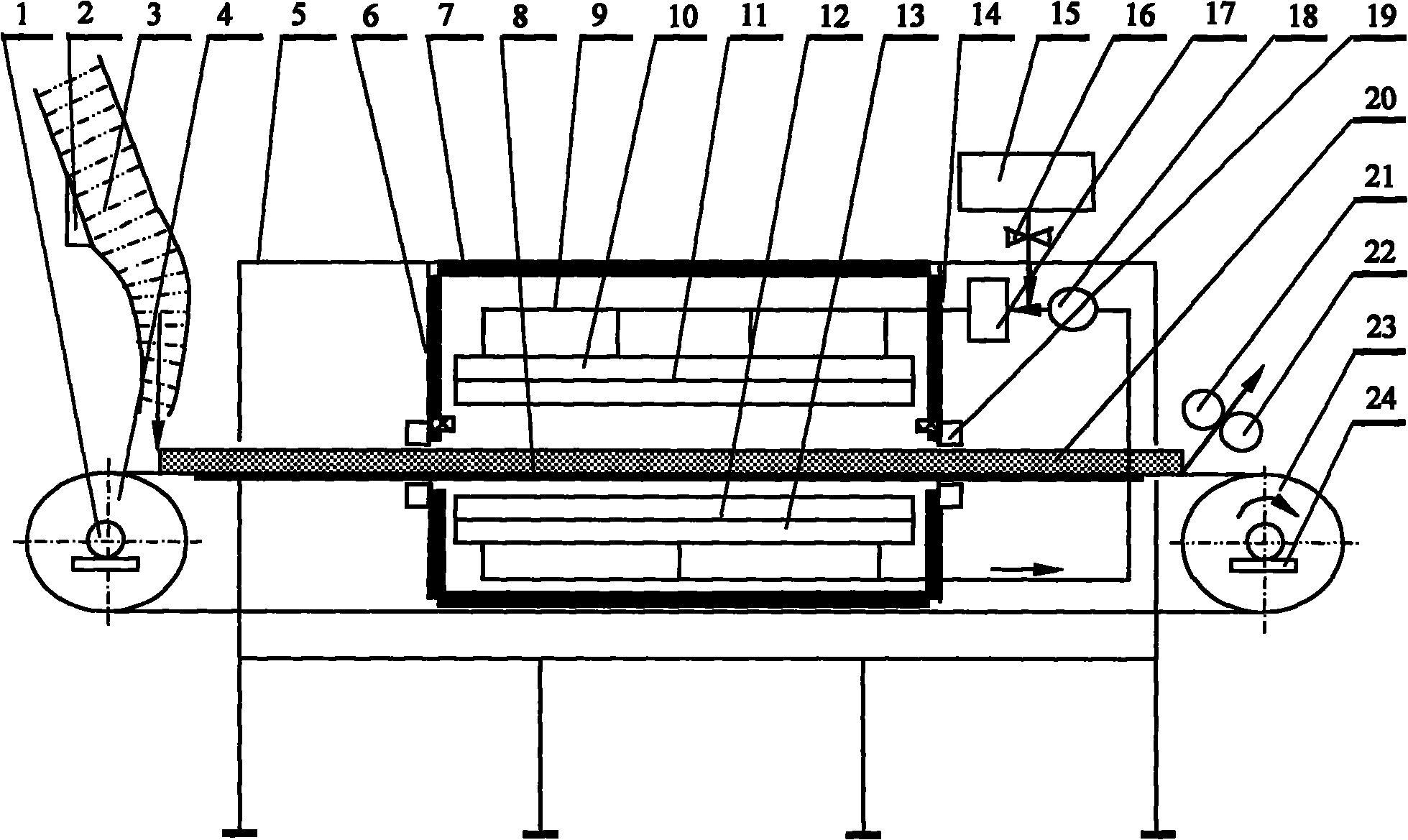

[0023] A kind of aramid fiber high temperature setting machine, such as figure 1 with figure 2 As shown, the curtain mesh driven wheel 4 is installed on the driven wheel bracket 1, the curtain mesh electric roller 23 is installed on the electric roller bracket 24, the curtain mesh bracket 8 is connected with the chassis shell 5, and the metal curtain mesh 29 is supported by the curtain mesh The support of frame 8 moves in parallel on screen net bracket 8. The wire guide plate 3 is installed on the wire guide plate support 2, and the tow passes through the wire guide plate 3 to form an equal-thickness laying layer 20 on the metal curtain 29. Roller 21 and lower silk roller 22. The chassis shell 5 is horizontally installed on the adjustable machine feet 30, and the level adjustment of the chassis shell 5 can be carried out. Inner box body 25 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com