Grain bin transverse nitrogen-charging adjustment system and storage method

A technology for filling nitrogen and grain depots, applied in chemical instruments and methods, botany equipment and methods, nitrogen compounds, etc., can solve problems such as shortage, achieve less nitrogen waste, high nitrogen filling efficiency, and good gas distribution uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

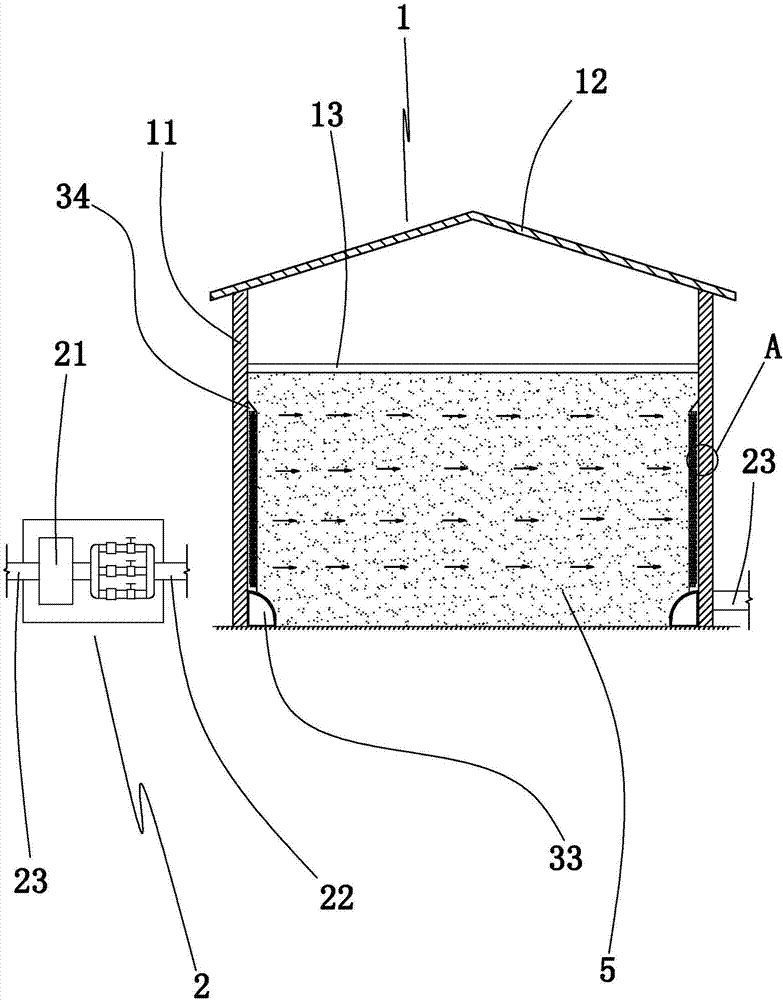

[0039] Example 1: Such as Figure 1 to Figure 6 As shown in the figure, a grain storage lateral nitrogen charging system includes a grain storage storage body 1 and a membrane separation nitrogen generator 2, and also includes two air-conditioning air duct structures. The grain storage body includes two parallelly arranged long sides. Side wall 11, short side walls and roof 12 arranged in parallel on both sides, the lower end of the long side wall is connected to the ground, the lower end of the short side wall is connected to the ground, and the air-conditioning air duct structure corresponds to the long side wall one by one;

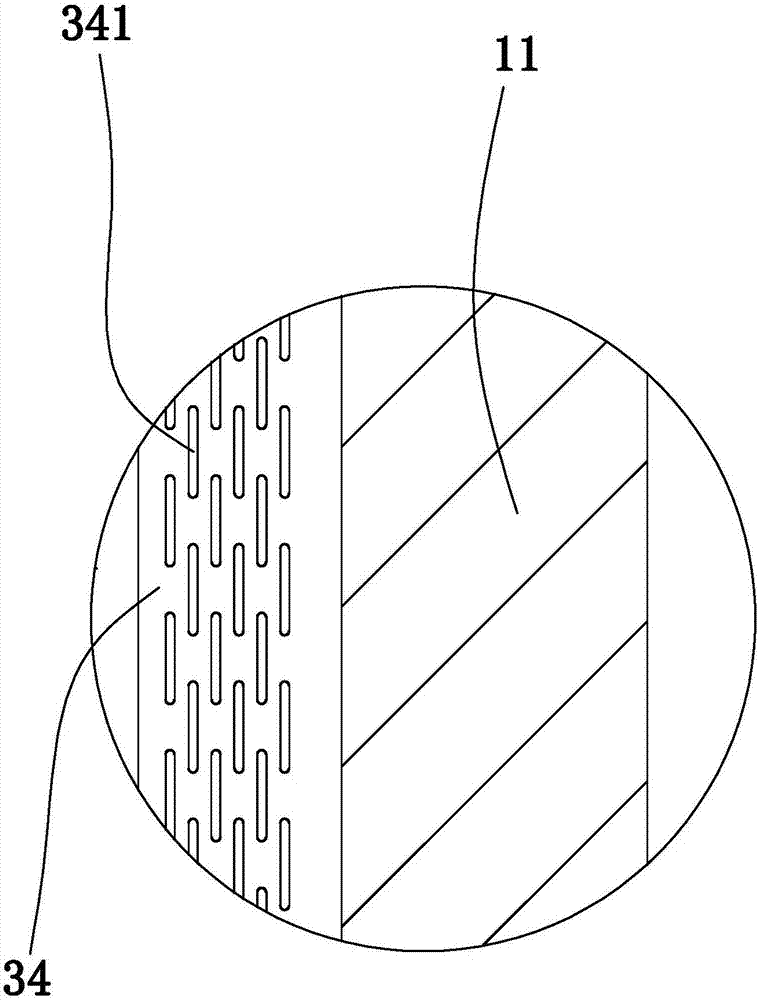

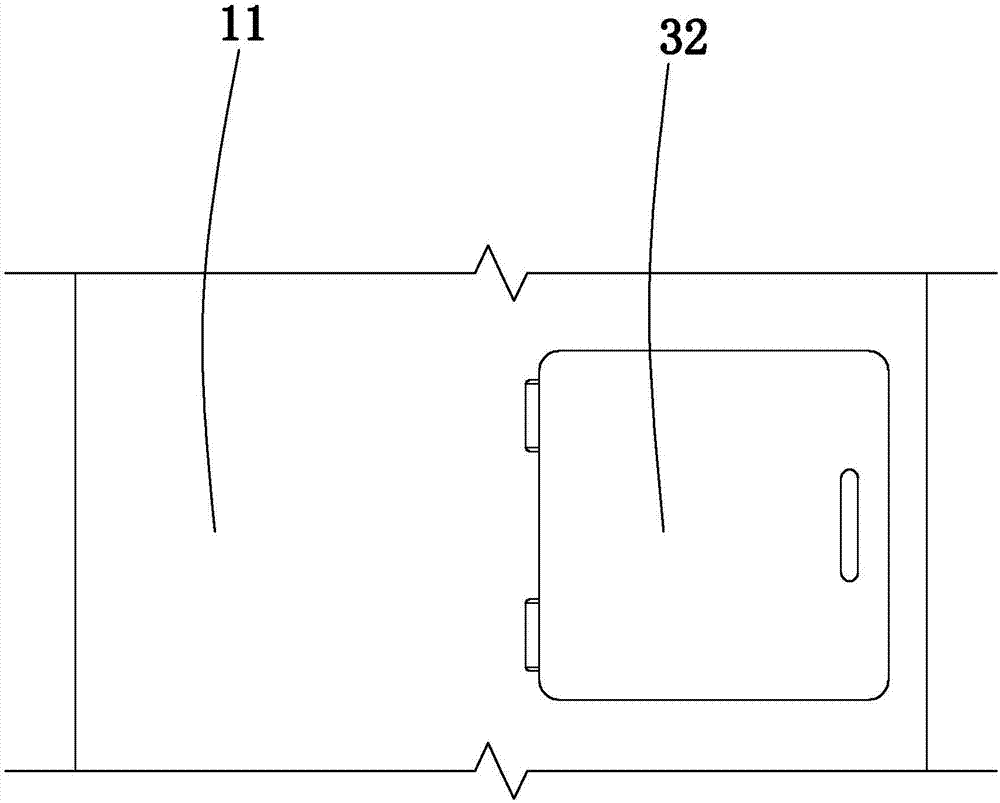

[0040] In the corresponding air channel structure and long side wall: the air channel structure includes a wall air channel 31 arranged on the long side wall, an opening and closing door 32 that can be used to close one end of the wall air channel, and another wall air channel. A main air pipe 33 connected at one end and a plurality of vertical branch air ...

Embodiment 2

[0048] Embodiment 2: The basic structure and implementation of this embodiment are the same as those of Embodiment 1, the difference lies in that Figure 7 to Figure 12 As shown in the corresponding air-conditioning air duct structure and long side wall: the air-conditioning air duct structure also includes a rear glue cylinder 36 arranged on the long side wall, and the long side wall is provided with several embedded long side walls. The first rubber storage tube 41 in the side wall, a number of second rubber storage tubes 42 embedded in the long side wall, and a number of third rubber storage tubes 43 embedded in the long side wall, the wall airway is cylindrical, and the wall airway diameter Upward, the first rubber storage tube is between the inner sealing ring and the wall air passage, the second rubber storage tube is between the inner sealing ring and the outer sealing ring, and the third rubber storage tube is between the outer sealing ring and the outer edge of the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com