Inert gas protection system for industrial adsorber and operation control method thereof

An inert gas and protection system technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as damage to adsorbent material equipment, achieve cost savings, ensure normal operation, and effectively alarm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

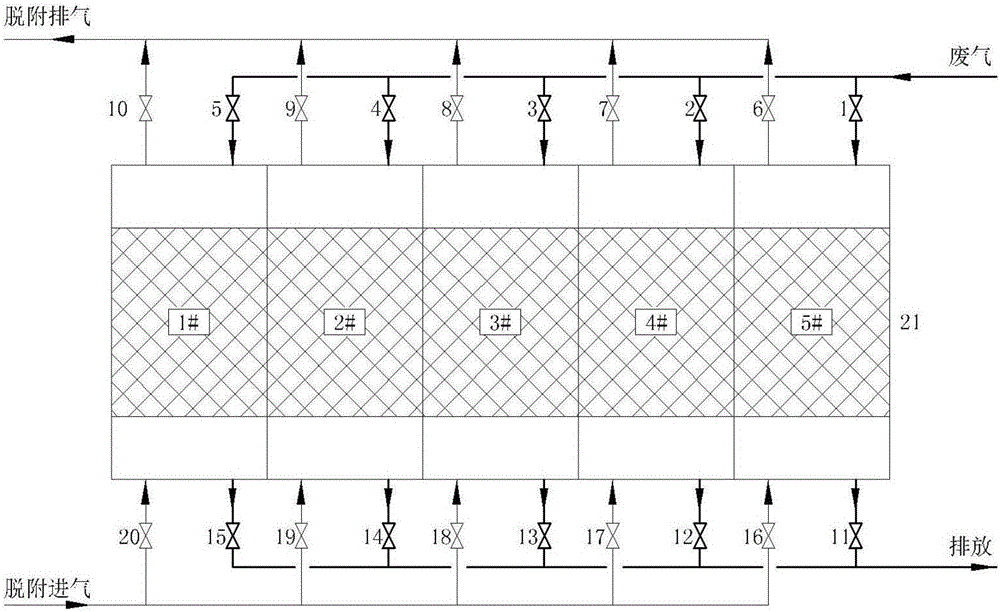

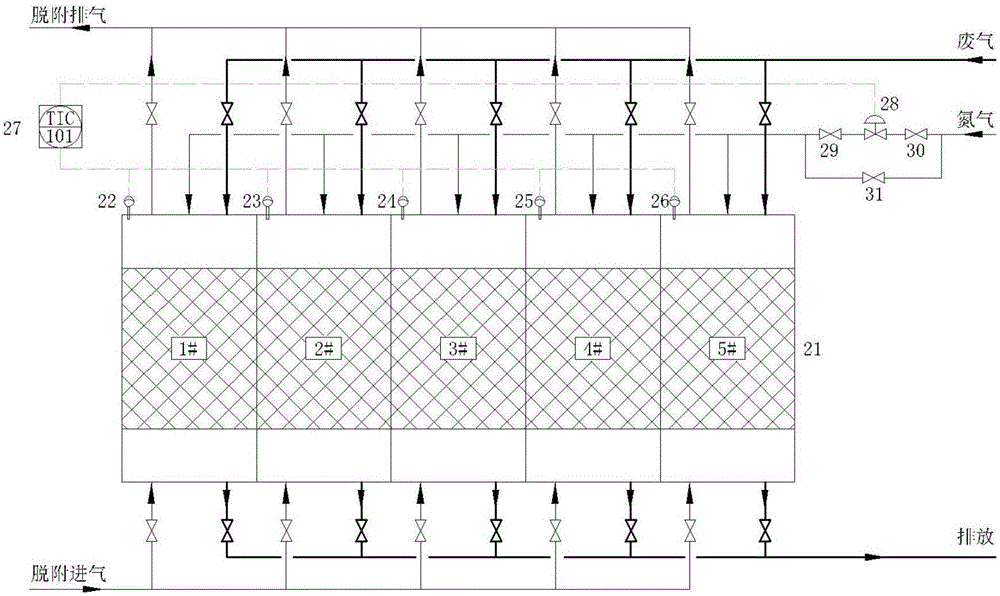

[0051] combine Figure 1-2 , an inert gas protection system for industrial adsorbers, including a multi-chamber split combined adsorber 21 and an inert gas inlet, and also includes a temperature controller 27 and a temperature detection element, and the multi-chamber split combined adsorber 21 is provided with There is an inert gas inlet, and the temperature detection element is located in the multi-chamber split combined adsorber 21. The temperature detection element is electrically connected to the temperature controller 27, and the temperature controller 27 controls the inert gas in and out of the inert gas inlet.

[0052] The temperature detection element detects the temperature signal in the multi-chamber split combined adsorber 21 and transmits it to the temperature controller 27. Once the temperature of the multi-chamber split combined adsorber 21 is too high, the temperature controller 27 controls the inert gas from the inert gas The air inlet enters into the multi-cha...

Embodiment 2

[0056] An inert gas protection system for industrial adsorbers, including a multi-chamber split combined adsorber 21 and an inert gas inlet, and also includes a temperature controller 27 and a temperature detection element. The multi-chamber split combined adsorber 21 is equipped with In the inert gas inlet, the temperature detection element is located in the multi-chamber split combined adsorber 21. The temperature detection element is electrically connected to the temperature controller 27, and the temperature controller 27 controls the inert gas in and out of the inert gas inlet.

[0057] The multi-chamber split combined adsorber 21 is also provided with an adsorption air inlet, an adsorption air outlet, a desorption air inlet and a desorption air outlet, which are connected with the adsorption air inlet, the adsorption air outlet, and the desorption air inlet. The pipeline connected to the desorption outlet and the desorption exhaust port is equipped with an adsorption inta...

Embodiment 3

[0059] This embodiment is similar to Embodiment 1-2, except that the number of adsorbers in the multi-chamber split combined adsorber 21 is greater than or equal to one; each adsorber is equipped with a temperature detection element; each temperature The detection element detects the temperature signal in each adsorber in the multi-chamber split combined adsorber 21 and transmits it to the temperature controller 27. Once the temperature in any one of the multi-chamber split combined adsorber 21 is too high, The temperature controller 27 controls the inert gas to enter the adsorber of the multi-chamber split combined adsorber 21 from the inert gas inlet, and the inert gas is continuously filled into the multi-chamber split combined adsorber 21 to cool down and replace the Oxygen, to achieve fire extinguishing, cooling function.

[0060] Once the temperature of an adsorber in the multi-chamber split combined adsorber 21 is too high, from figure 2 It can be seen from the figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com