Mechanical cleaning system for underground storage tank of filling station

A technology for mechanical cleaning and gas station, which is applied to the field of mechanical cleaning system for buried oil tanks in gas stations, can solve the problems of large area of the whole system, centralized venting, complicated separation and processing equipment of cleaning products, etc., and achieves the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

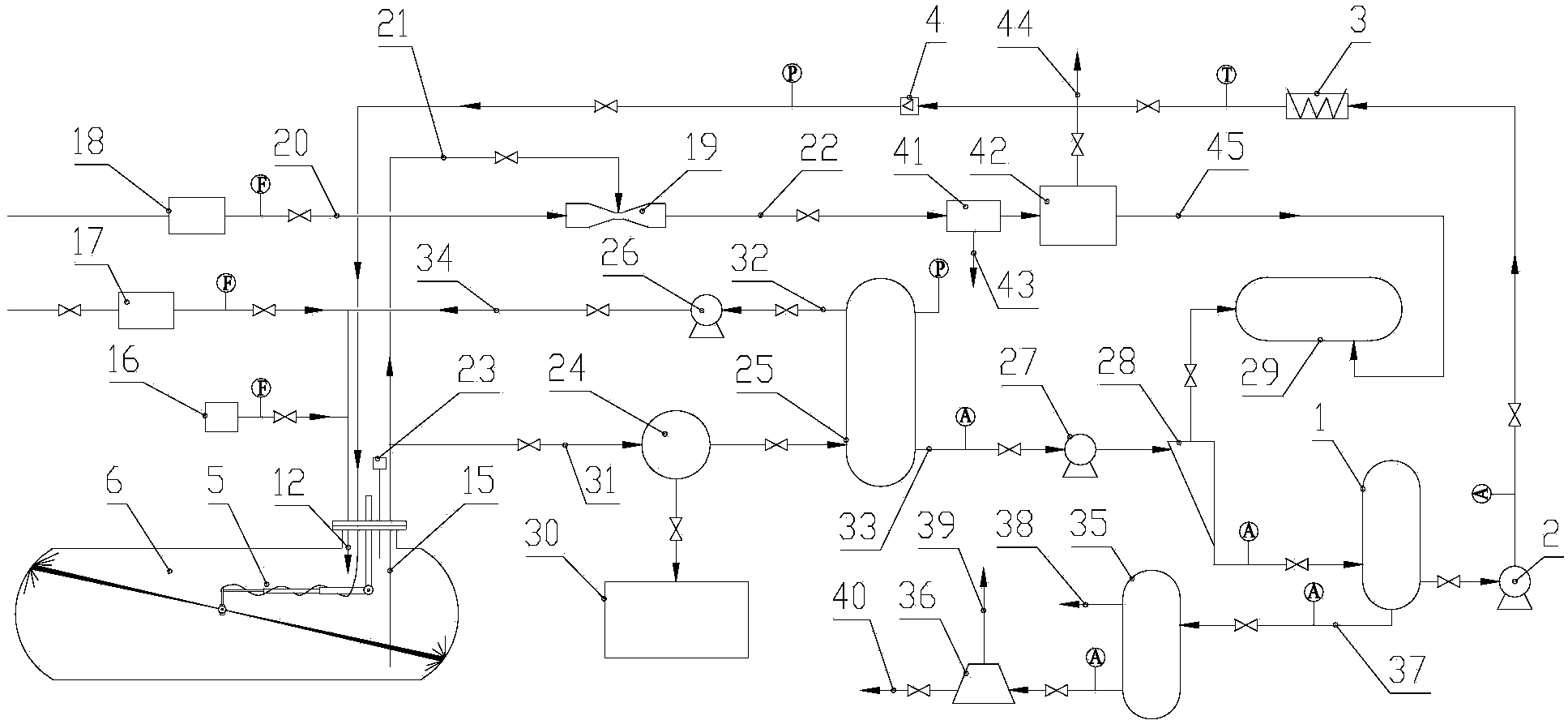

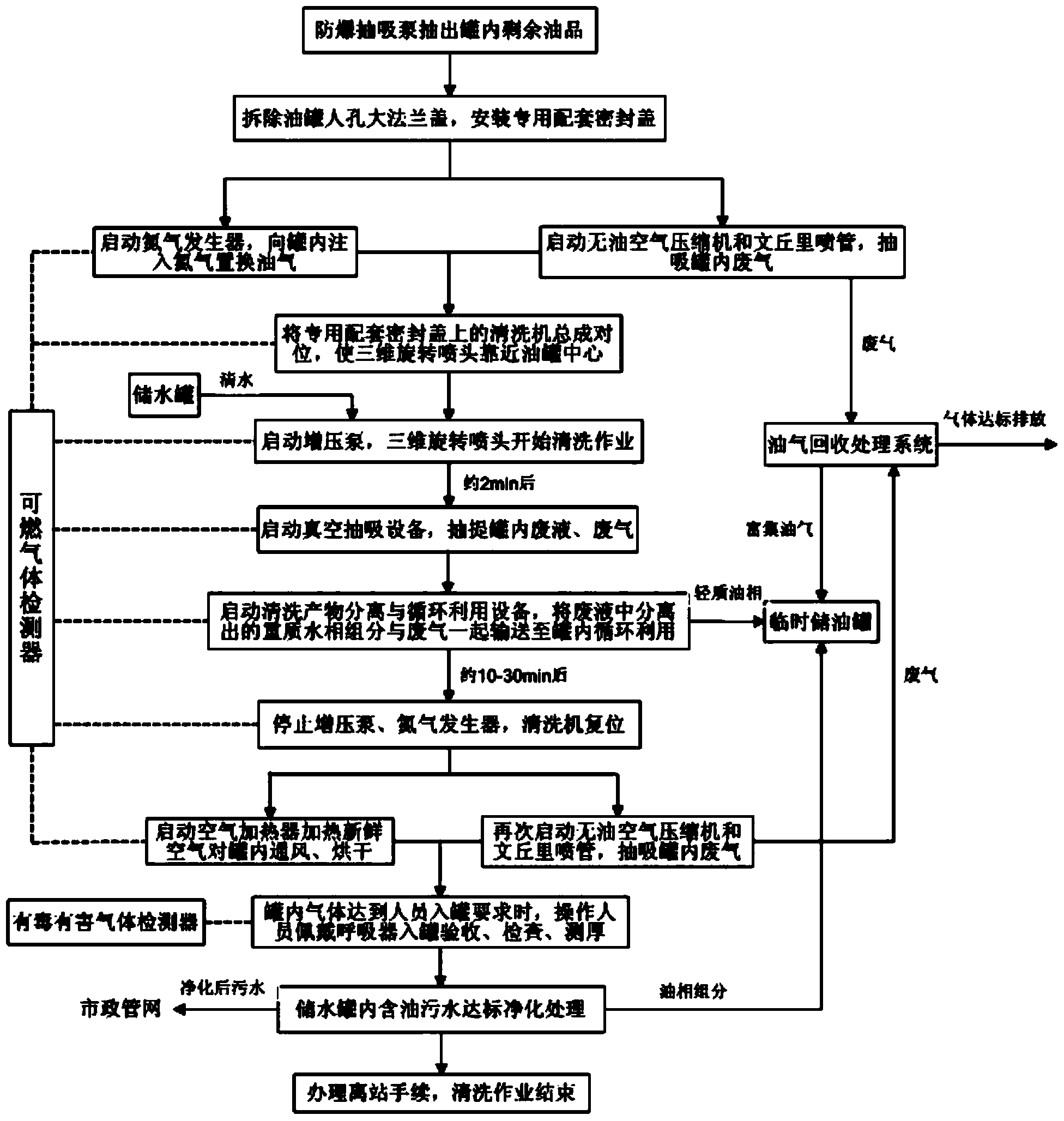

[0042] Such as figure 1 , figure 2As shown, the system mainly includes low-pressure jet cleaning equipment, air replacement equipment, gas atmosphere monitoring equipment, cleaning product separation treatment and recycling equipment, oily sewage outflow compliance treatment equipment and oil gas recovery treatment equipment, etc.

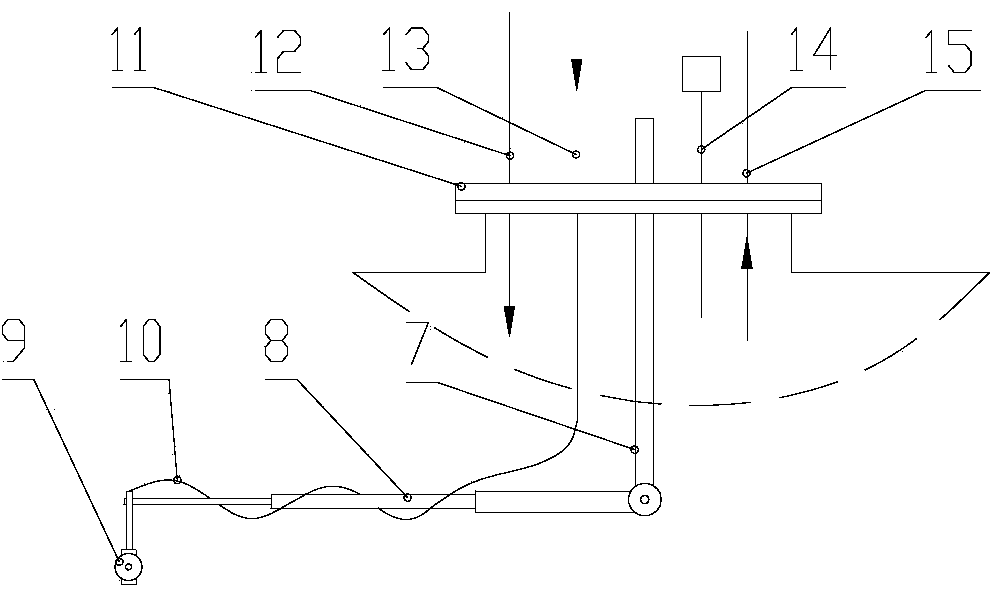

[0043] image 3 It is a schematic diagram of the installation of the washing machine on the special matching sealing cover. The special matching sealing cover 11 is also integrated with a nitrogen injection pipe joint 12, a water supply pipe joint 13, a gas atmosphere monitoring sampling pipe joint 14 and a suction pipe joint 15, which greatly facilitates Each pipeline is connected to the cleaning machine and ensures that the cleaning process is carried out in a closed state.

[0044] The low-pressure spray cleaning equipment includes a water storage tank 1, a booster pump 2, a heater 3, a turbine flowmeter 4 and a washing machine 5, and each pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com