Remote monitoring and non-manual control device and method for nitrogen making machine

A technology of remote monitoring and nitrogen generator, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of waste of energy and human resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

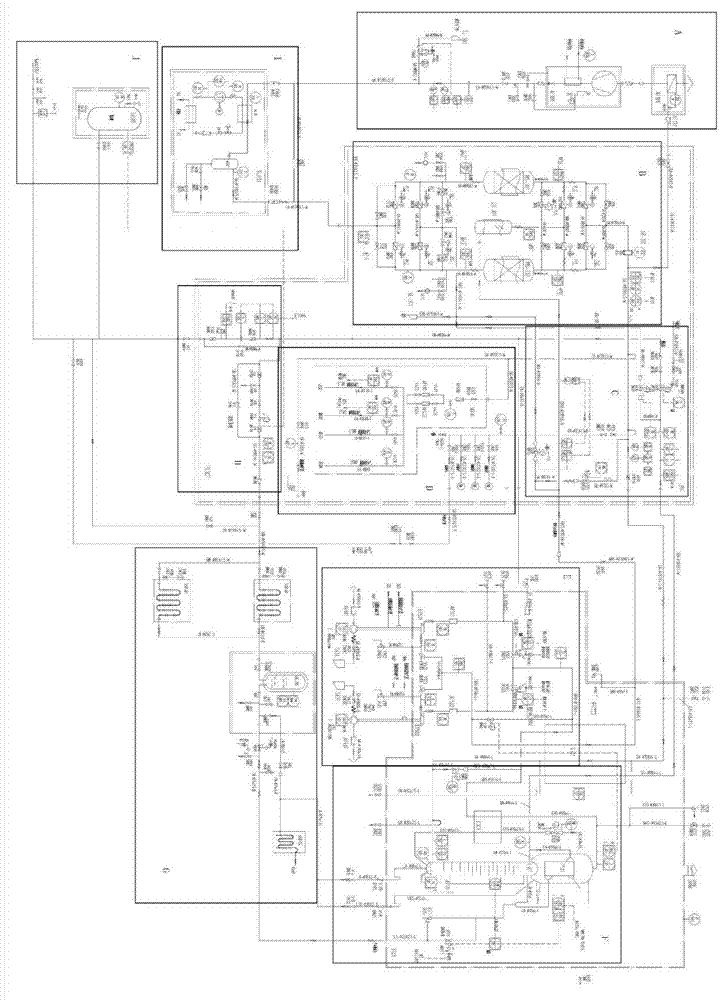

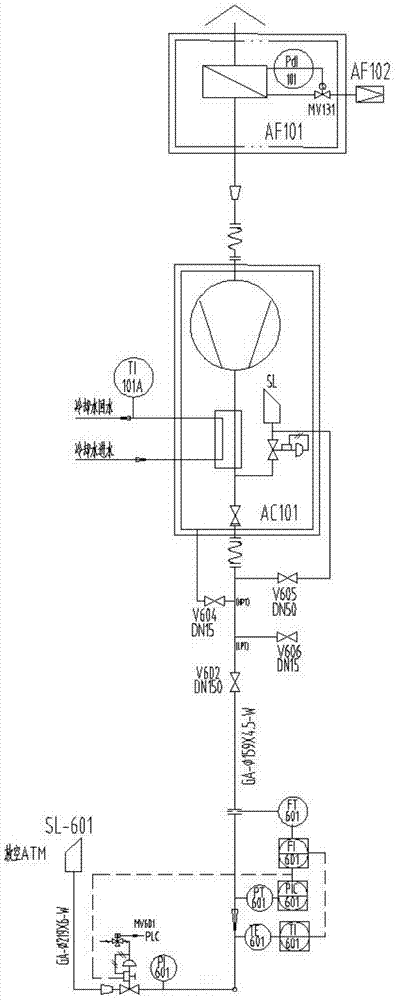

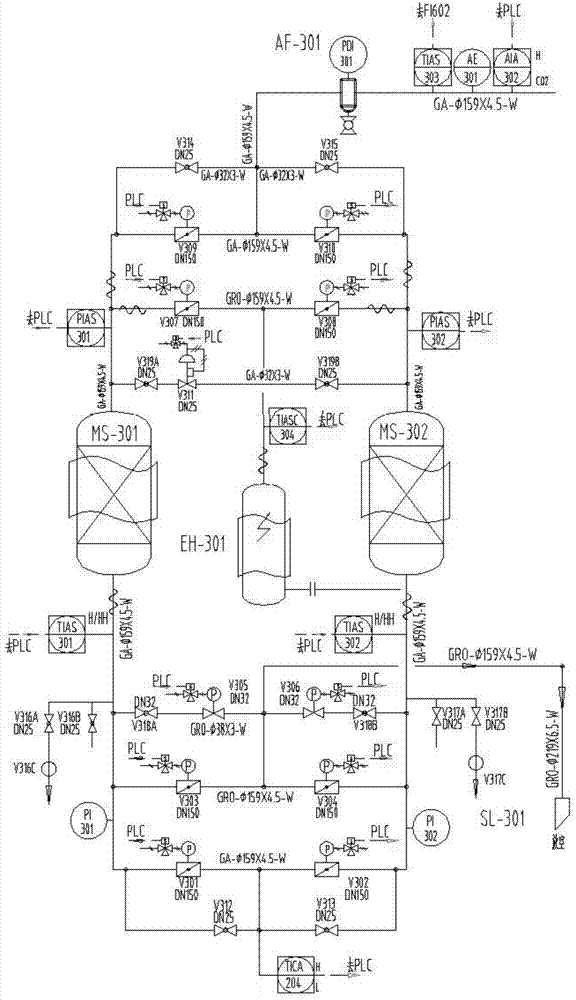

[0091] Such as Figure 1 to Figure 11 As shown, a device for remote monitoring and unmanned control of a nitrogen generator, including a network connection computer and a computer programming tool PLC system or DCS programming tool, one end of the filter AF102 on the air compression system A passes through the pipeline and the valve Connect the main air pipeline after the dust filter AF301 in the air pretreatment system B, lead the dry low-pressure air as the air source for the filter AF102 blowback, and the other end of the air compression system A is connected to the butterfly valve V606A on the water separation system I through the pipeline At one end, the outlet pipe of the dust filter AF301 on the air pretreatment system B is connected to the inlet end of the lower part of the rectification column in the cold box system F through the butterfly valve V612 on the analyzer system C, and the electric heater on the air pretreatment system B The intake pipe of EH-301 is connect...

Embodiment 2

[0093] A method for remote monitoring and unmanned control of a nitrogen generator, including a computer connected to a network and a PLC programming application tool. The method adopts a cryogenic method to separate air, and the compressed air enters rectification after passing through a molecular sieve adsorber to remove impurity gases. The tower, at low temperature, undergoes rectification at the outlet of the tower top product to obtain product nitrogen. The whole system consists of air compression system, pre-cooler, purifier, electric heater, expander refrigeration system, heat exchanger, rectification tower equipment, transmission Transportation and storage system, analyzer system, and instrument control system. The hardware of all electrical equipment in the whole system is equipped with two start-up methods: local and remote. Through the PLC-type DCS programming control system and safety protection system, the system is guaranteed. The safe and stable start-up, operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com