Gear engaging control method for dual-clutch automatic transmission with synchronizer

A technology of automatic transmission and double clutch, applied in the direction of transmission control, elements with teeth, belt/chain/gear, etc., can solve the problem of not considering the moving speed of the shift fork, etc., to ensure the success rate and avoid changing The effect of blocking shock and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] specific implementation plan

[0042] The specific embodiment of the patent of the present invention is described in detail below in conjunction with accompanying drawing:

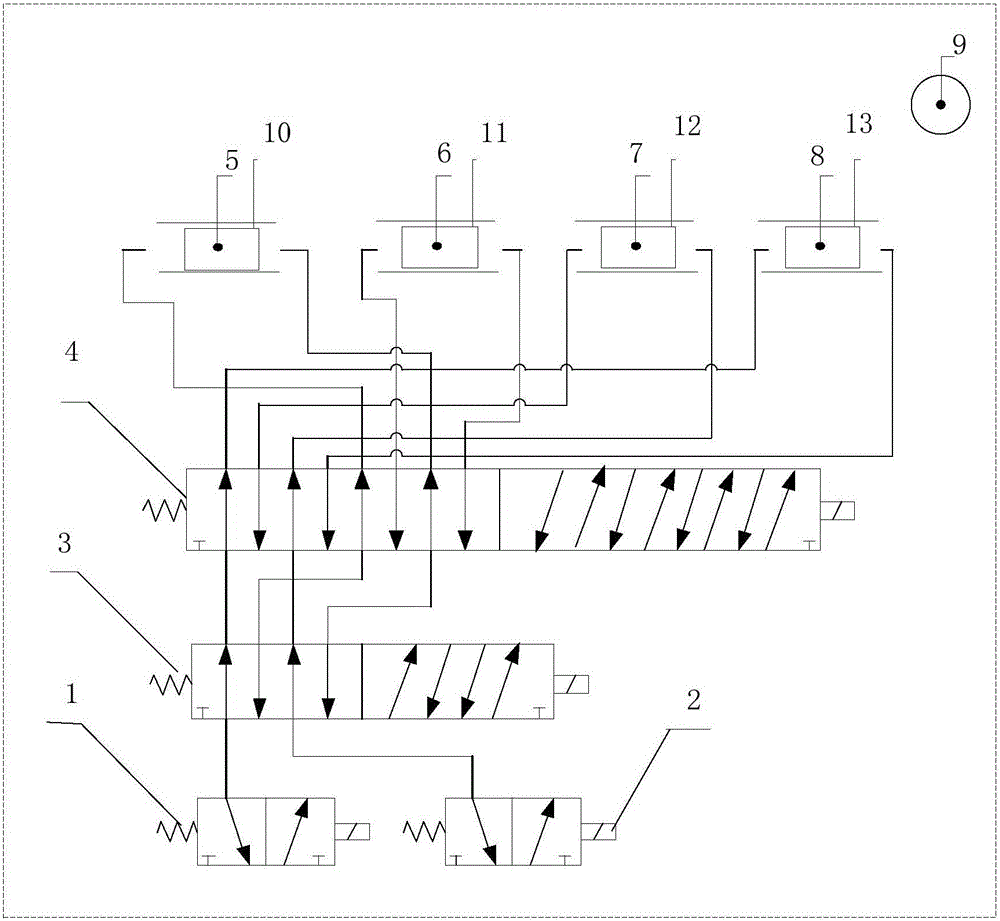

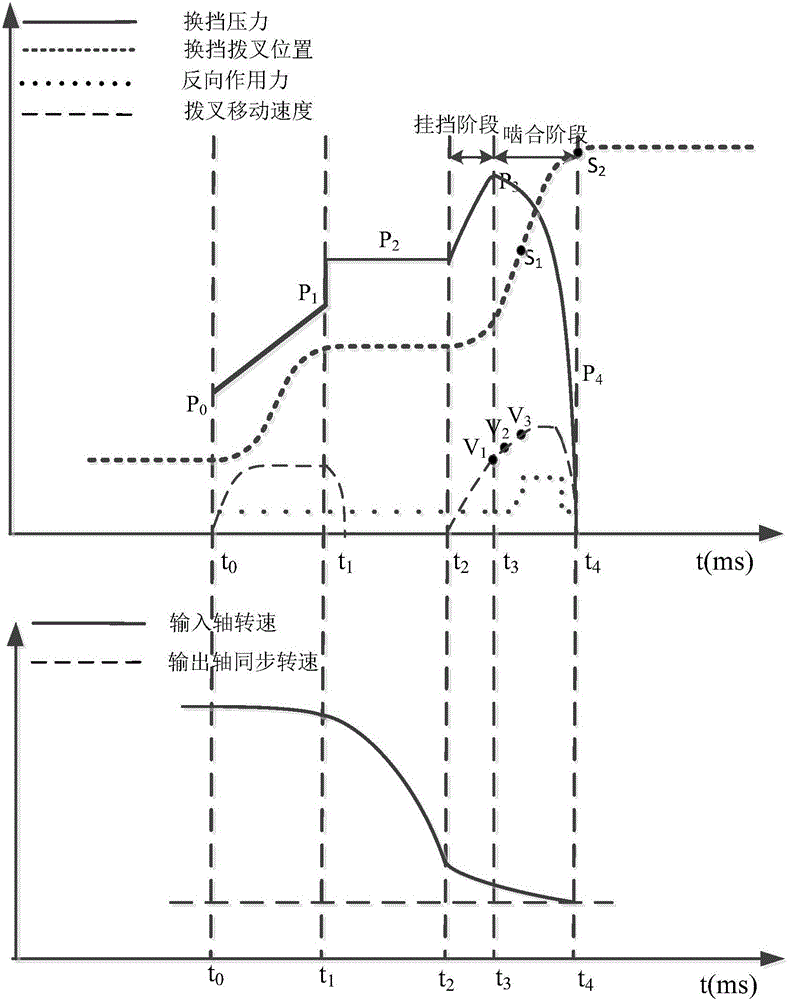

[0043] The present invention adopts a double-clutch automatic transmission with a hydraulic actuator, and the hydraulic shift actuator realizes the shifting action through a shift solenoid valve 1, a shift solenoid valve 2, a shift multi-way valve 1, and a shift multi-way valve 2 The control of the shift solenoid valve 1 and 2 is connected with the shift multi-way valve 1 and 2, and the shift multi-way valve 1 and 2 is connected with 4 shift forks, and the system has 4 shift forks Fork position sensor, 1 oil temperature sensor. Such as figure 1As shown, taking the 2nd gear as an example, first select and control the shift fork where the 2nd gear is located according to the 2 shift multi-way valves, and then open the shift solenoid valve 1, and the shift fork moves to the direction of the 2nd gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com