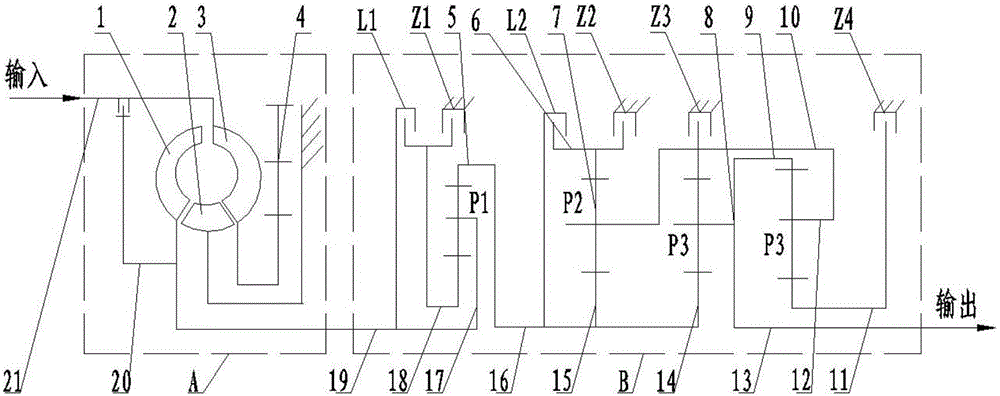

High-power hydraulic variable speed transmission device

A technology of hydraulic transmission and transmission, which is applied in the direction of transmission, fluid transmission, transmission control, etc., which can solve the problems of super long and heavy installation, large mass, and difficult layout, so as to reduce the shock of shifting and reduce the axial size. Reduce and improve the effect of transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

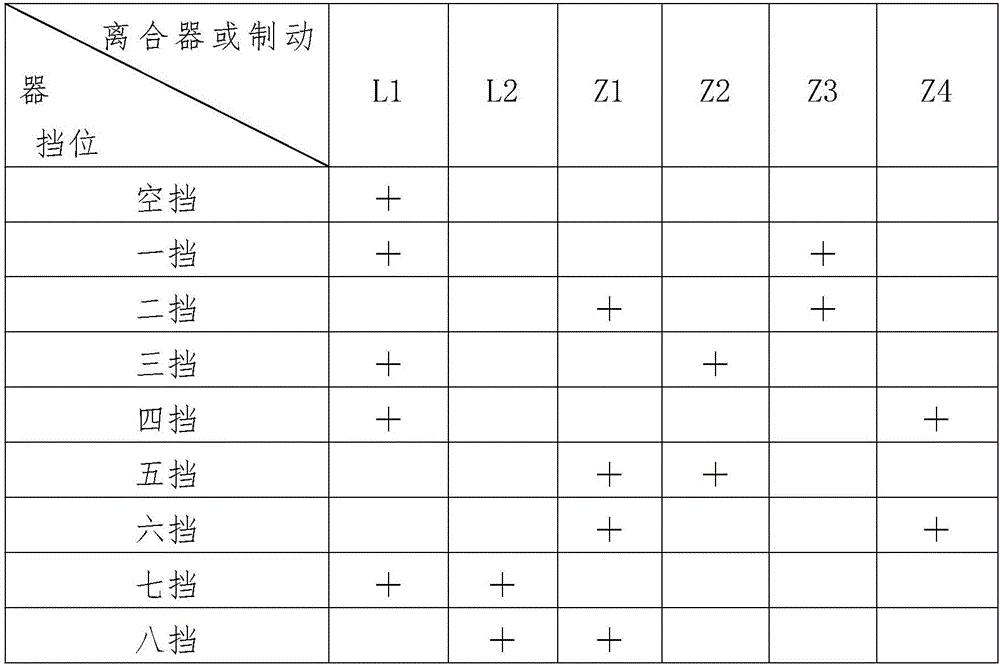

[0017] 1. Neutral gear: only the L1 rotating clutch is combined, the turbine output shaft 19, the L1 rotating clutch, the sun gear D18, the planetary carrier D17, and the ring gear A5 rotate together as a whole, and the torque is transmitted to the intermediate shaft 16 through the ring gear A5, due to the rotation of L2 Clutches, Z2 brakes, Z3 brakes, and Z4 brakes are not combined, there is no torque output, and neutral gear is realized.

[0018] 2. First gear: combination of L1 rotary clutch and Z3 brake. After the L1 rotary clutch is combined, the turbine output shaft 19, the L1 rotary clutch, the sun gear D18, the planet carrier D17, and the ring gear A5 rotate together as a whole, and the torque is transmitted to the intermediate shaft 16 through the ring gear A5, and the intermediate shaft 16 is at the same angular velocity Rotate and drive the sun gear B14 to rotate as a whole; the Z3 brake is combined, the ring gear D10 brakes, the torque passes through the sun gear B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com