Preloaded spring self-restoring energy-dissipating support

A technology of pre-compressed springs and energy-dissipating supports, applied in building components, earthquake-proof and other directions, can solve the problems of difficult reinforcement and repair, irreparable repair, poor hysteretic energy dissipation capacity, etc., to reduce residual deformation, easy to repair and replace, shorten the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The preferred embodiments will be described in detail below in conjunction with the accompanying drawings.

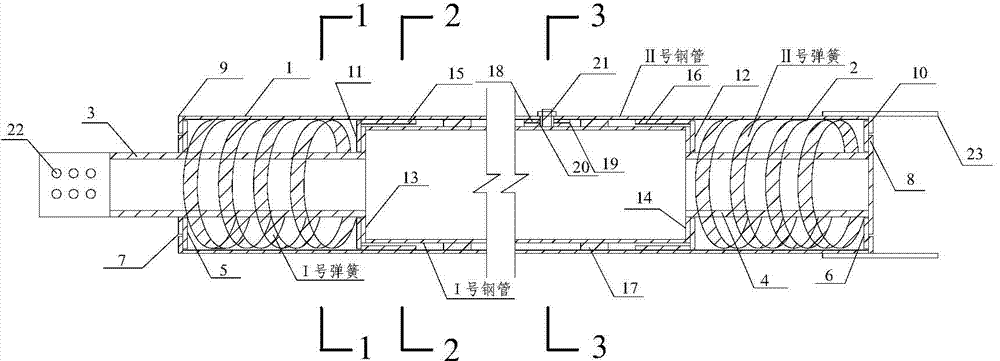

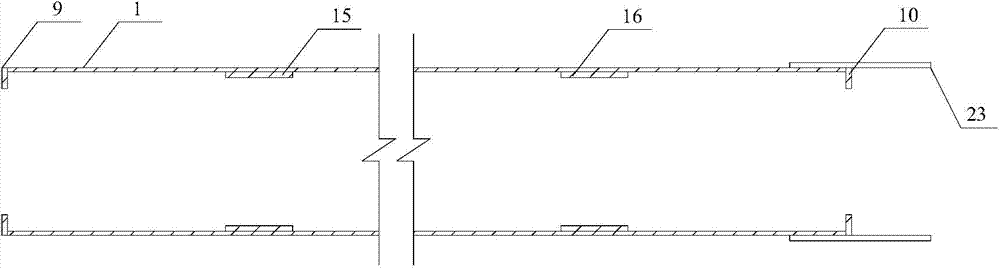

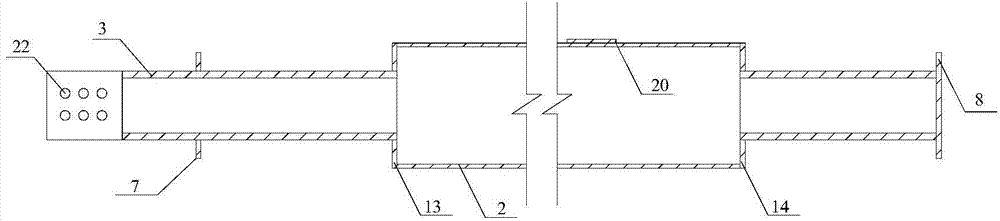

[0034] Such as figure 1Shown is a schematic structural view of the self-restoring energy-dissipating support of the pre-compressed spring of the present invention. The support includes an inner tube, an outer tube, a spring, a spring baffle, and a guide block. The inner tube, the outer tube and the spring constitute a restoring device, the spring provides restoring force, and the inner tube and the outer tube transmit force. The inner friction plate 18 of the outer tube, the outer friction plate 20 of the inner tube and the high-strength bolts 21 constitute an energy dissipation device to dissipate the energy input by the earthquake. The spring is composed of No. Ⅰ spring and No. Ⅱ spring. The outer diameter of the spring is smaller than the inner diameter of the left outer tube 1 and the right outer tube 2, and larger than the outer diameter of the left inner t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com