Motor-driven planetary gear train gear shifting mechanism

A technology for planetary gear trains and shifting mechanisms, applied to mechanical equipment, transmission parts, components with teeth, etc., to achieve the effects of simple installation structure, compact structure, simplified internal structure and external installation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

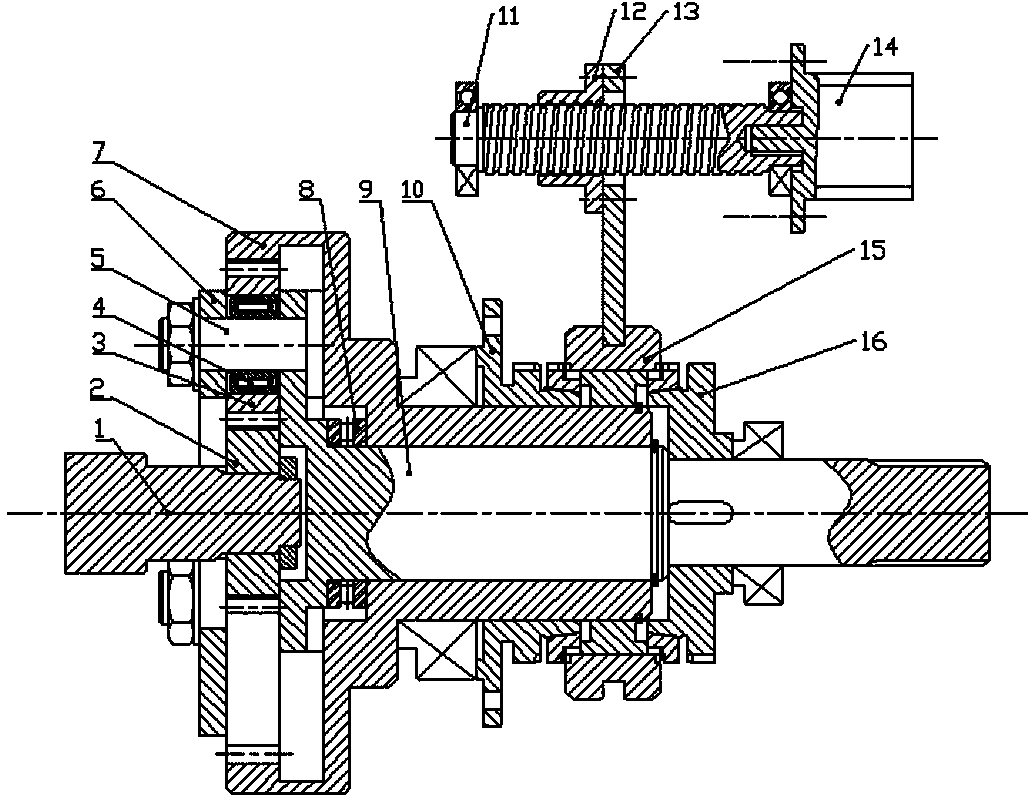

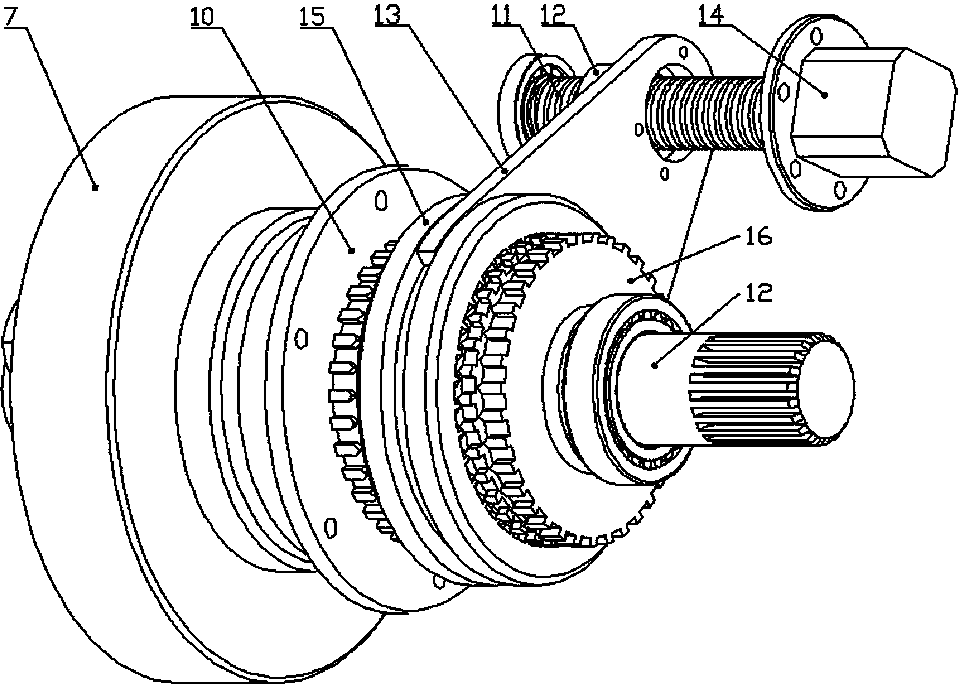

[0021] see figure 1 and figure 2 , A motor-driven planetary gear shift mechanism is composed of a planetary gear mechanism, a synchronizer 15 and a shift fork mechanism.

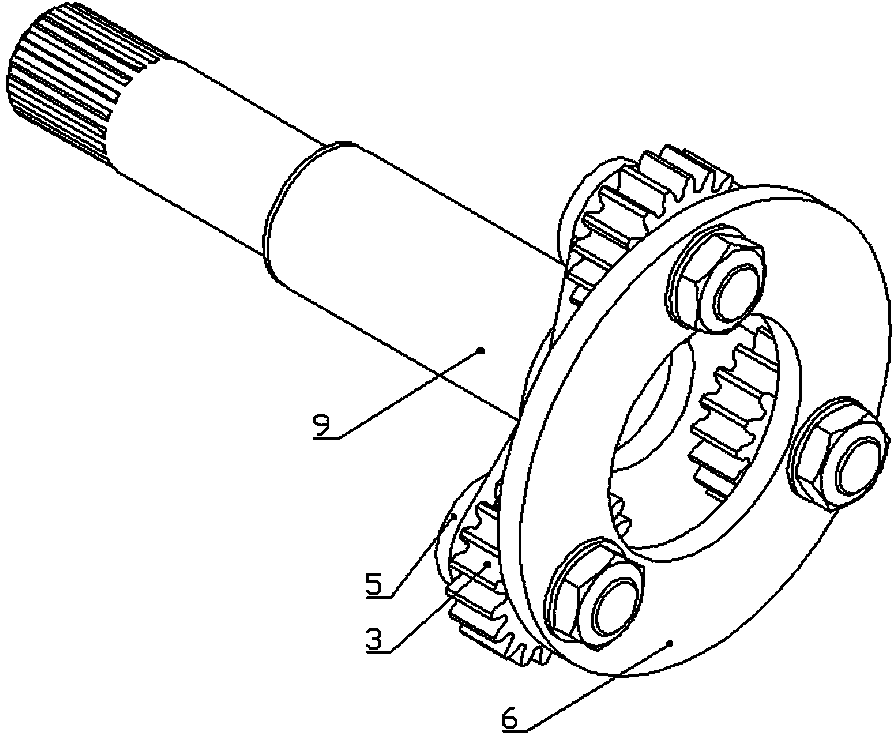

[0022] see figure 1 and image 3 , the planetary gear train mechanism includes a center wheel 2, an inner ring gear 7, a planet carrier 9 and three planetary wheels 3, the center wheel 2 is fixedly installed on one end of the input shaft 1, and the center wheel 2 and the input shaft 1 are connected through a spline fit, The shaft end of the input shaft 1 is fixed by a lock nut, and the other end of the input shaft 1 is the input end. The planet carrier 9 is formed by a disk coaxially connected with a rotating shaft, see image 3 , three planetary gears 3 are evenly distributed on the disk through the planetary gear shaft 5, and needle bearings 4 are installed between e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com