Motor and speed changer integrated power assembly for battery electric vehicles

A pure electric vehicle and powertrain technology, applied in the direction of electric power devices, power devices, vehicle components, etc., can solve the problems of large shifting impact and cost increase, and achieve small shifting impact, low production cost, and overall structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with the accompanying drawings, the present invention will be further described through embodiments.

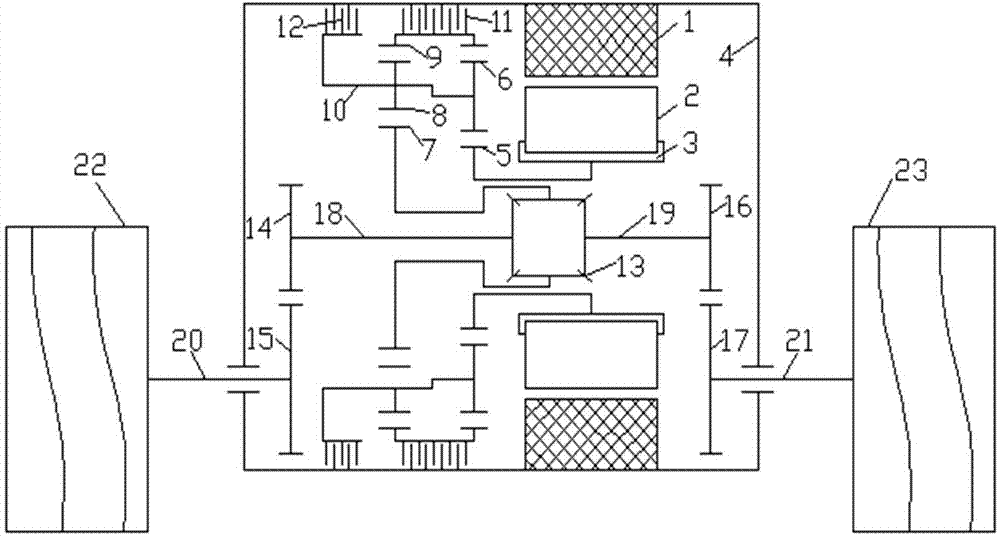

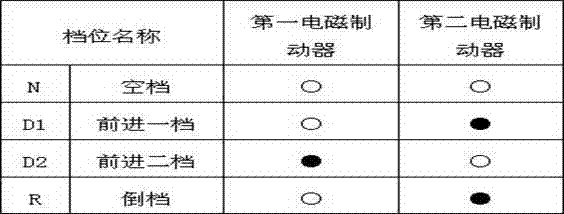

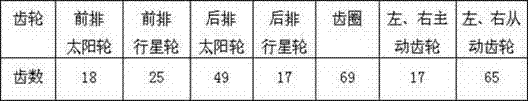

[0020] see figure 1 , a powertrain that integrates the motor and transmission of a pure electric vehicle, including the motor, the transmission and the differential 13; the motor includes a stator 1, a rotor 2 and a rotor seat 3, and the stator 1 is located on the inner wall of the motor housing 4 , the rotor 2 is sleeved on the tubular rotor seat 3; the axial end of the rotor seat 3 is provided with a front row sun gear 5; the front row sun gear 5 is fixed at one end of the second hollow wheel shaft, and the other end of the second hollow wheel shaft passes through The splines are fixedly connected to the rotor base 3 , and the second hollow wheel shaft is coaxially sleeved on the first hollow wheel shaft on one side of the differential 13 . The inner wall of the motor housing 4 is also provided with a first electromagnetic brake 11 and a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com