Control device and control method for pneumatic automated mechanical transmission gear shifting force

A technology of automatic transmission and control device, which is applied in the direction of transmission control, mechanical equipment, components with teeth, etc., and can solve problems such as increasing the difficulty of system control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

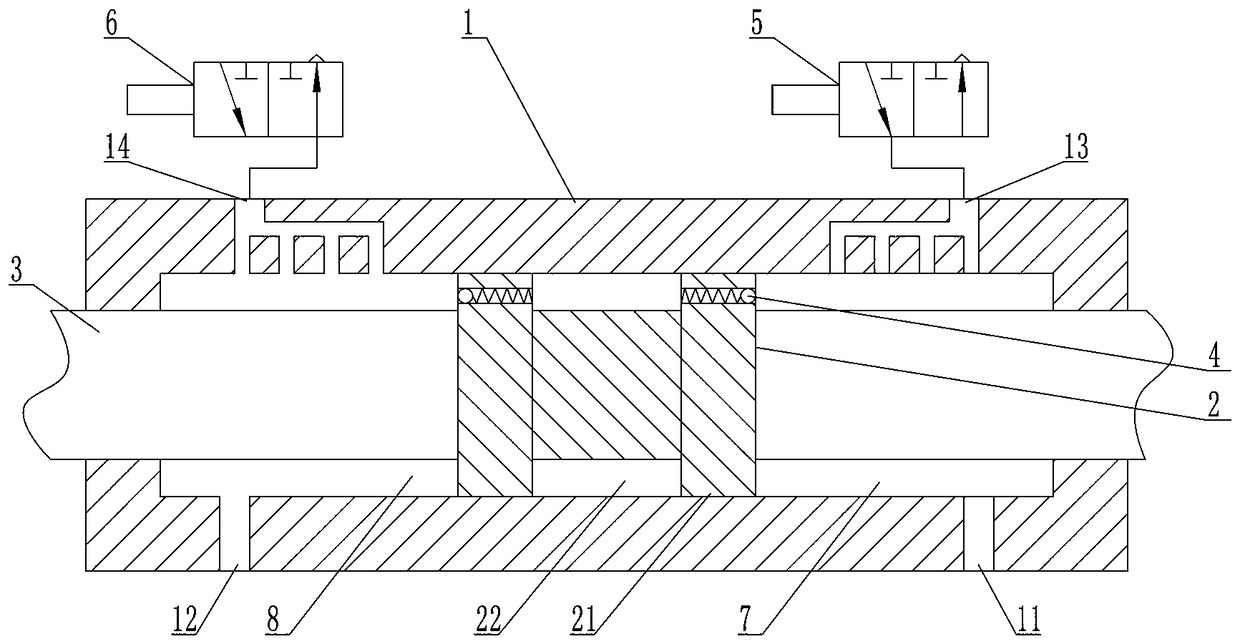

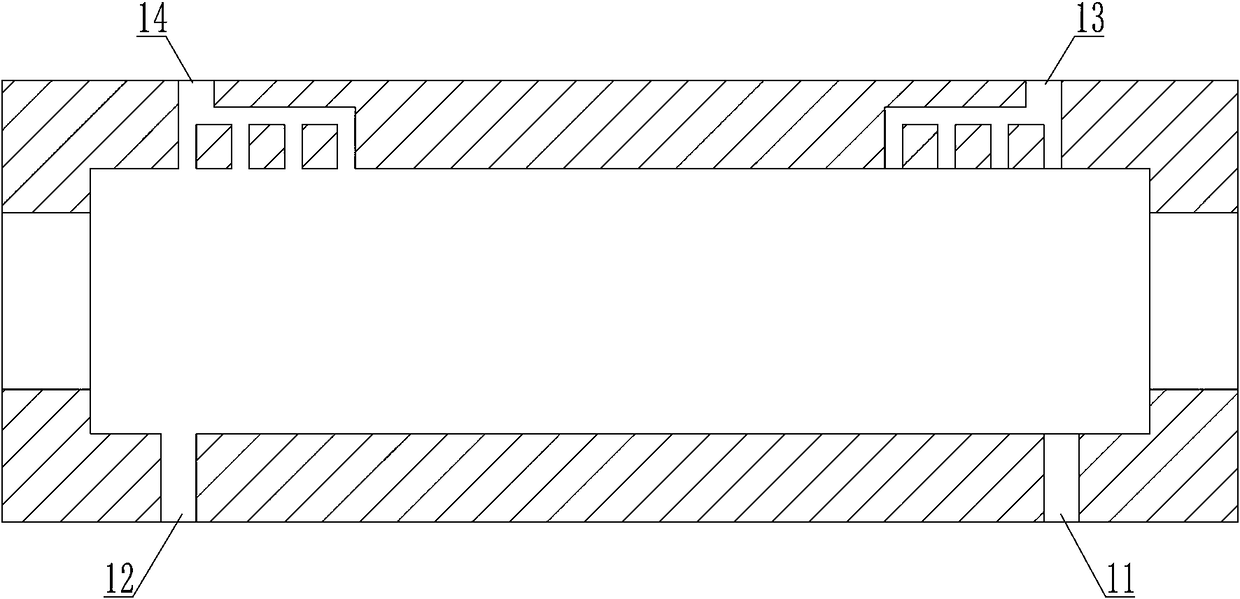

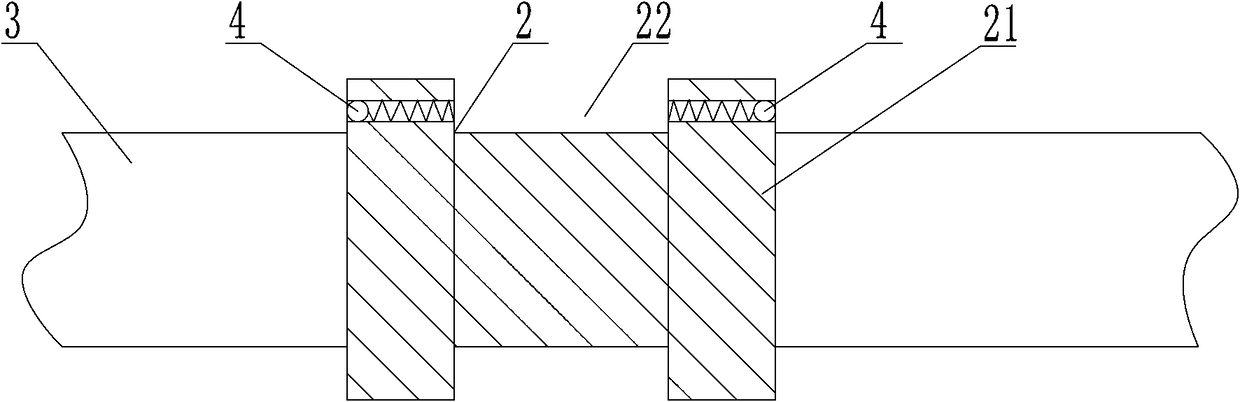

[0029] Such as Figure 1~Figure 5 Among them, a control device for shifting force of a pneumatic mechanical automatic transmission, which consists of a control valve piston 2 connected to a push rod 3 and a hollow valve body 1 that cooperates and slides to separate the valve body 1 into a right cavity 7 and a left cavity 8 The valve body 1 is provided with a first air inlet 11 and a first interface 13 communicating with the right cavity 7, a second air inlet 12 and a second interface 14 communicating with the left cavity 8, and the piston 2 There is a quick exhaust valve 4 at the end, and the first solenoid valve 5 and the second solenoid valve 6 communicate with the first port 13 and the second port 14 respectively. The structure is simple, and the first solenoid valve 5 and the second solenoid valve 6 are de-energized and energized to control the communication between the double-piston cylinder and the valve body 1, and the intake or exhaust drive the control valve piston 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com