Gear shift control device for hybrid vehicle drive system

A hybrid vehicle and drive system technology, applied in the direction of hybrid vehicles, power units, and engine-driven traction, can solve the problems of discontinuous shifting impact of driving torque, etc., to reduce shifting impact and suppress fluctuations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

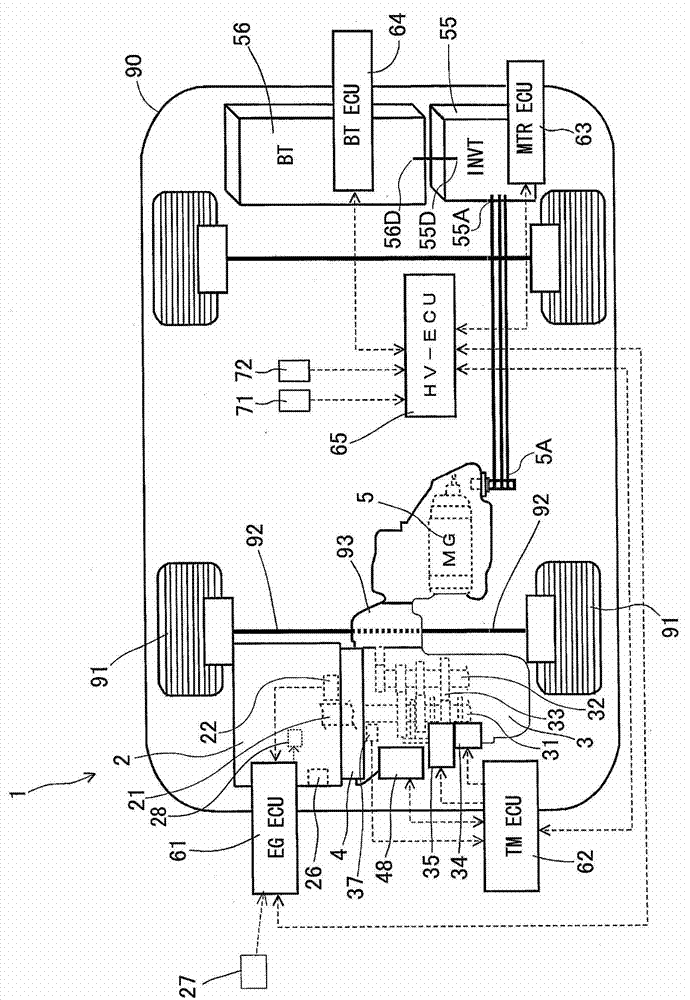

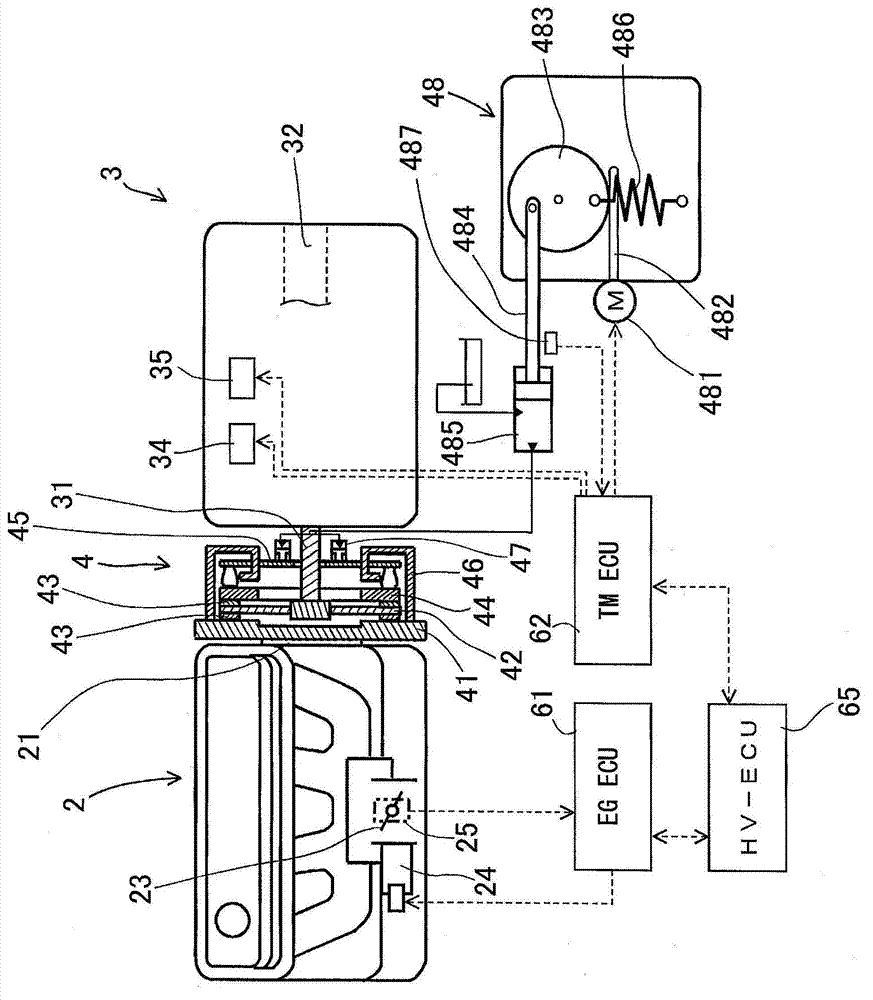

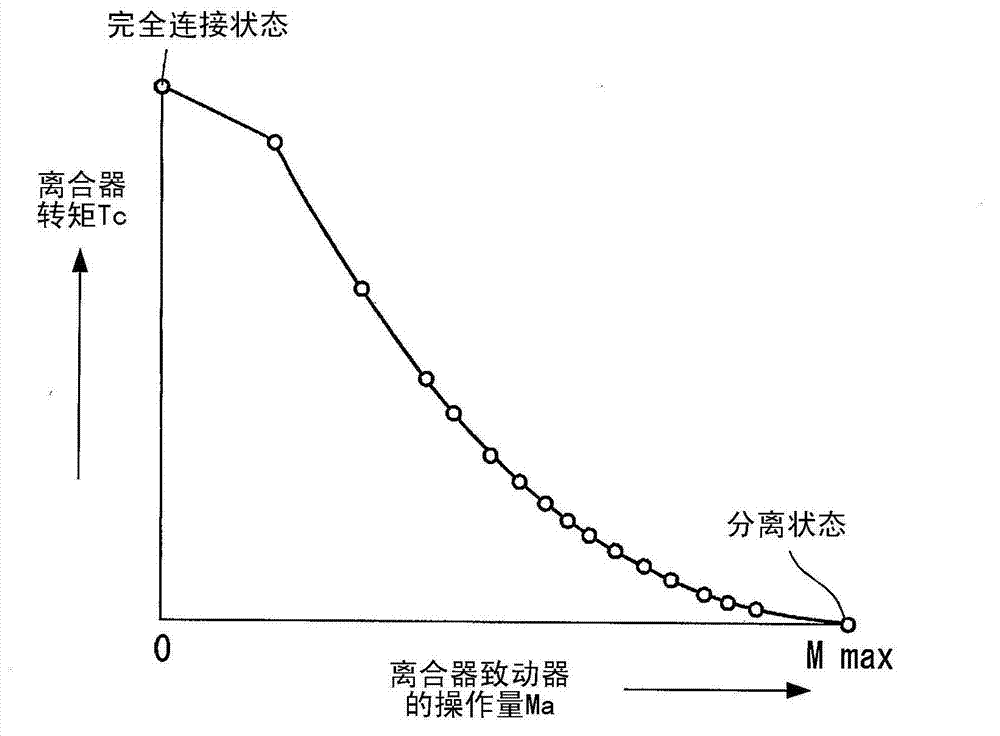

[0027] The following will refer to Figure 1 to Figure 8 One embodiment of a transmission control device for a drive system of a hybrid vehicle is explained.

[0028] like figure 1 As shown, a hybrid vehicle drive system 1 is a front-engine, front-wheel-drive type (FF type) drive system, and an engine 2 serving as a drive source and a motor generator 5 are attached to a chassis The front portions of the wheels 90 are arranged in parallel so that the front drive wheels 91 are driven by either the engine 2 and the motor generator 5 or by both the engine 2 and the motor generator 5 simultaneously. A hybrid vehicle drive system 1 includes an automatic transmission 3 and a clutch 4 . exist figure 1 and figure 2 In , the dotted arrows connecting the elements show the flow of control.

[0029] like figure 1 As shown, the engine 2 is arranged transversely on the chassis 90 on the opposite front side of the axle 92 of the front drive wheels 91 . The engine 2, the clutch 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com