Non-stop three-section wheel rail-rack rail transition device for rack rail traffic system

A traffic system, three-stage technology, applied in the field of non-stop three-stage wheel-rail-rack transition device, which can solve the serious wear and tear of the gear and rack driving end structure, low system safety and reliability, and increase operation Maintenance costs and other issues to achieve the effect of improving system safety and stability, ensuring driving safety, and facilitating maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the drawings and embodiments.

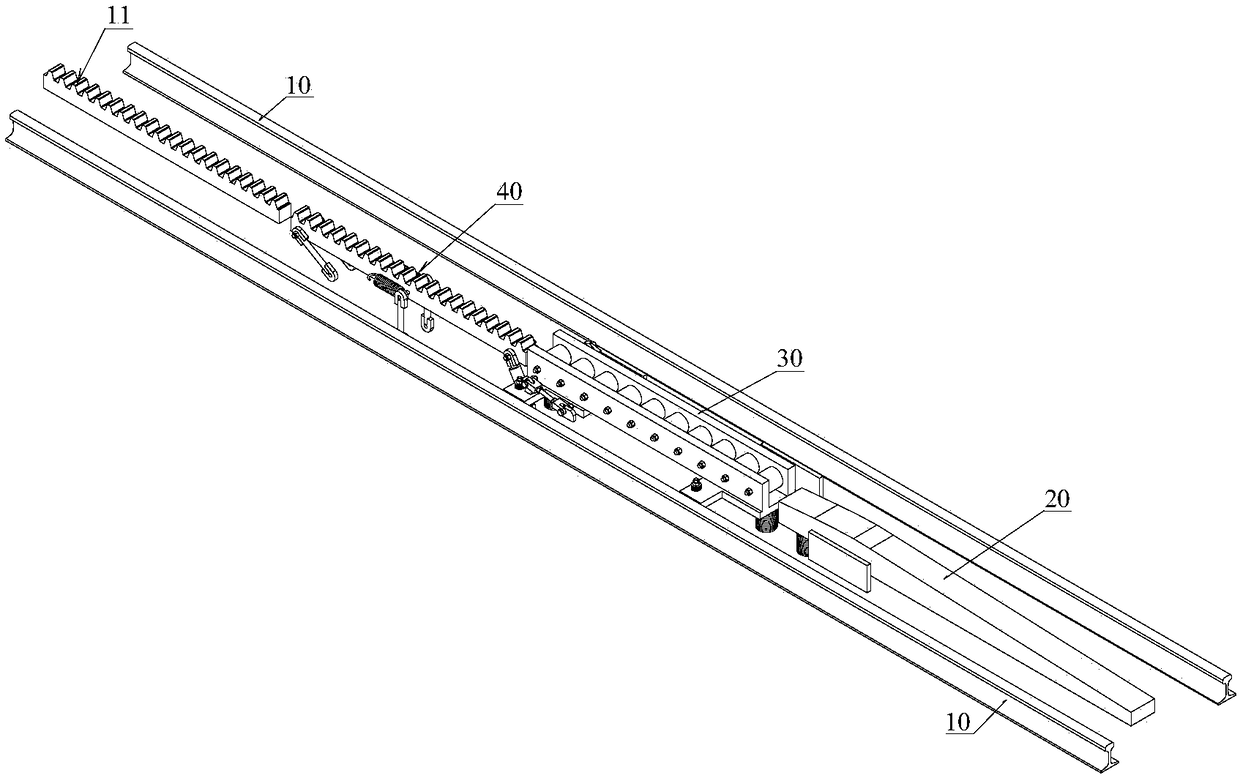

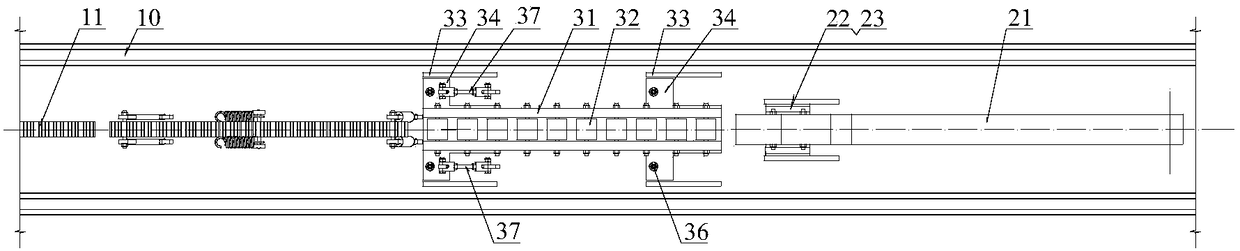

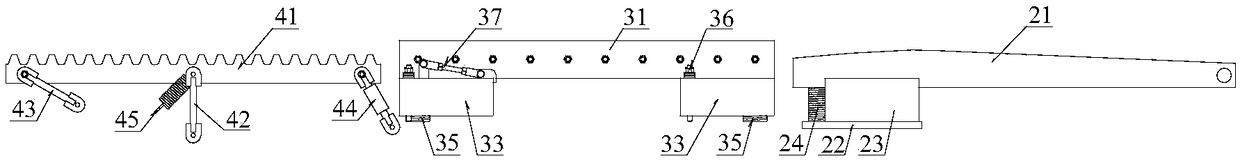

[0023] Reference figure 1 , figure 2 with image 3 , The non-stop three-stage wheel-rail-to-rack transition device for a rack-track transportation system of the present invention includes a rack 11 installed between the steel rails 10 on both sides. The rack transition device 40, the drum transition device 30, and the inclined surface transition device 20 are sequentially arranged before the running-in end of the rack. The inclined surface transition device 20, the drum transition device 30 and the rack transition device 40 act on the vehicles passing the rack rail in sequence. The driving gears of the gear rails cause the drive wheels of the rack-mounted vehicle to slide relative to the steel rail 10 with vertical force, and when entering the starting end of the rack 11, the driving gears and the rack 11 form an effective meshing. The meshing of the drive gear and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com