Unidirectional clutch for preventing engagement gear of mashing gear

A technology for one-way clutches and meshing gears, applied in the direction of mutually meshing clutches, clutches, mechanical drive clutches, etc., can solve the problems of drive gear grinding damage, drive gear wear, top teeth, etc., to achieve extended service life and reliable performance , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

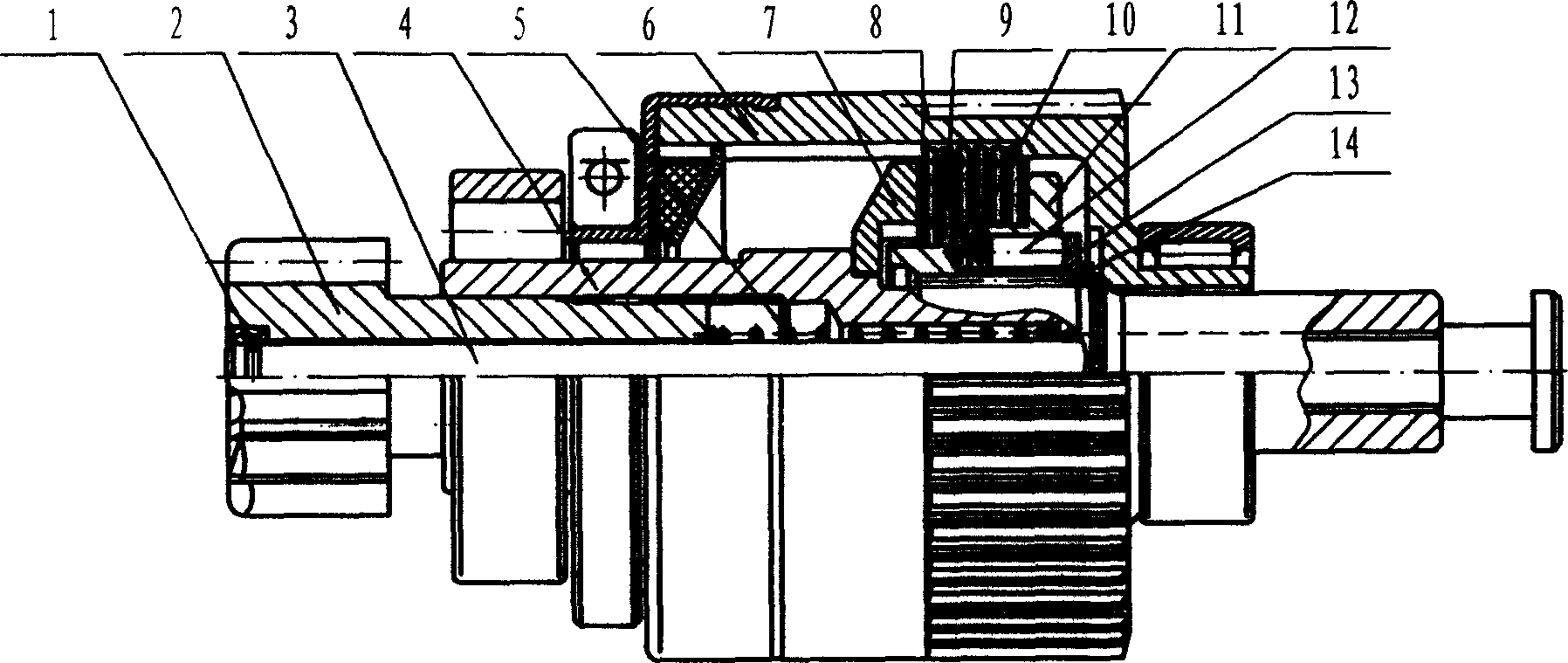

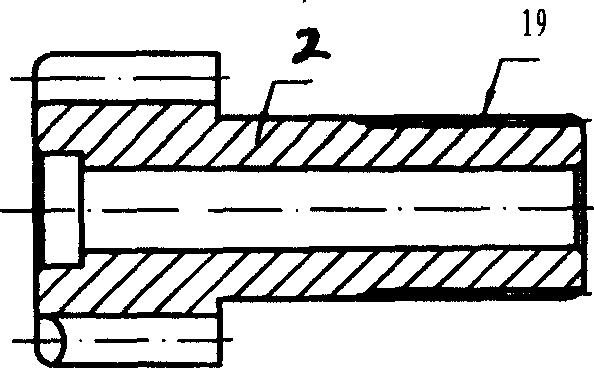

[0014] Embodiment 1: as figure 1 , 3 , shown in 4: after various parts are made according to the designed shape, the straight-tooth key 16 is processed on the inner wall of the hollow shaft 4, and the helical spline is processed at the place where the movable sleeve 7 is to be installed, so that the movable sleeve 7 is pushed forward When rotating with the angle of the helical spline, the friction copper sheet 9, the friction steel sheet 8 and the movable spacer 11 are successively installed on the movable sleeve 7, and the friction copper sheet 9 and the friction steel sheet 8 are overlapped layer by layer, and the The inner circumferential teeth of the friction steel plate 8 mesh with the keyway on the movable sleeve 7, and are fastened by the spring 10 and the positioning pin 12, and are installed on the hollow shaft 4 together, and then a flat washer 13 and a snap ring 14 are used to secure it. Fix it, insert it into the drive shell 6, and make the internal helical spline...

Embodiment 2

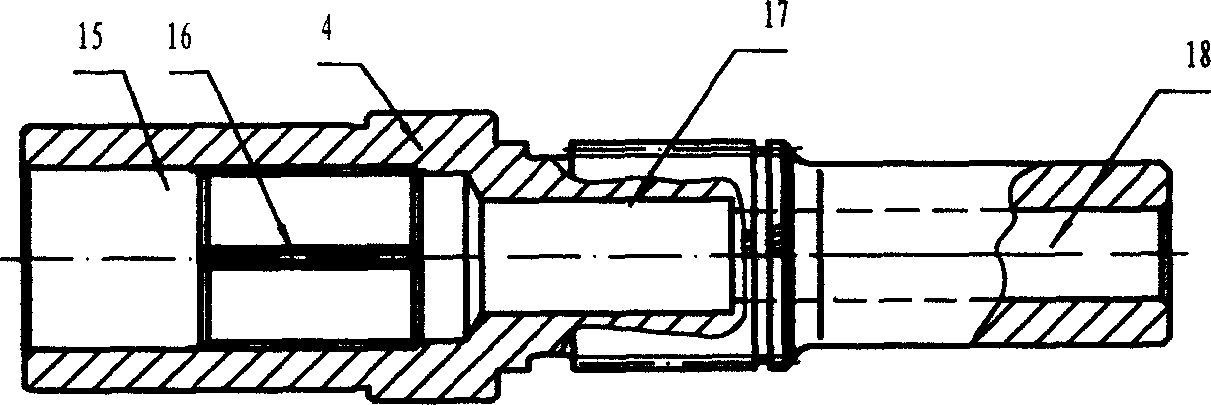

[0015] Embodiment 2: as figure 2 As shown, in the one-way clutch formed in Embodiment 1, the inner cavity of the hollow shaft 4 is respectively processed into a drive pinion movable cavity 15, a spring telescopic cavity 17 and a push rod cavity 18, and on the inner wall of the drive pinion movable cavity 15 A straight-toothed key 16 is set, and one end of the driving pinion 2 is also processed into a corresponding straight-toothed key 19, and the driving pinion 2 inserted in the movable cavity 15 of the driving pinion is connected with the straight-toothed key on the hollow shaft 4 through the straight-toothed key 19 16 meshes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com