Handling method for failure of static shifting of pure electric vehicle mechanical automatic transmission

A technology of automatic transmission and processing method, which is applied in the direction of mechanical equipment, transmission device control, and components with teeth, etc., and can solve the problem that the transmission cannot respond quickly to shifting intentions, the number of shifting failures increases, and the impact on vehicle drivability and safety In order to achieve the effect of shortening the time of shifting and re-engaging, reducing the torque of the shift ring and improving the success rate of re-engaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

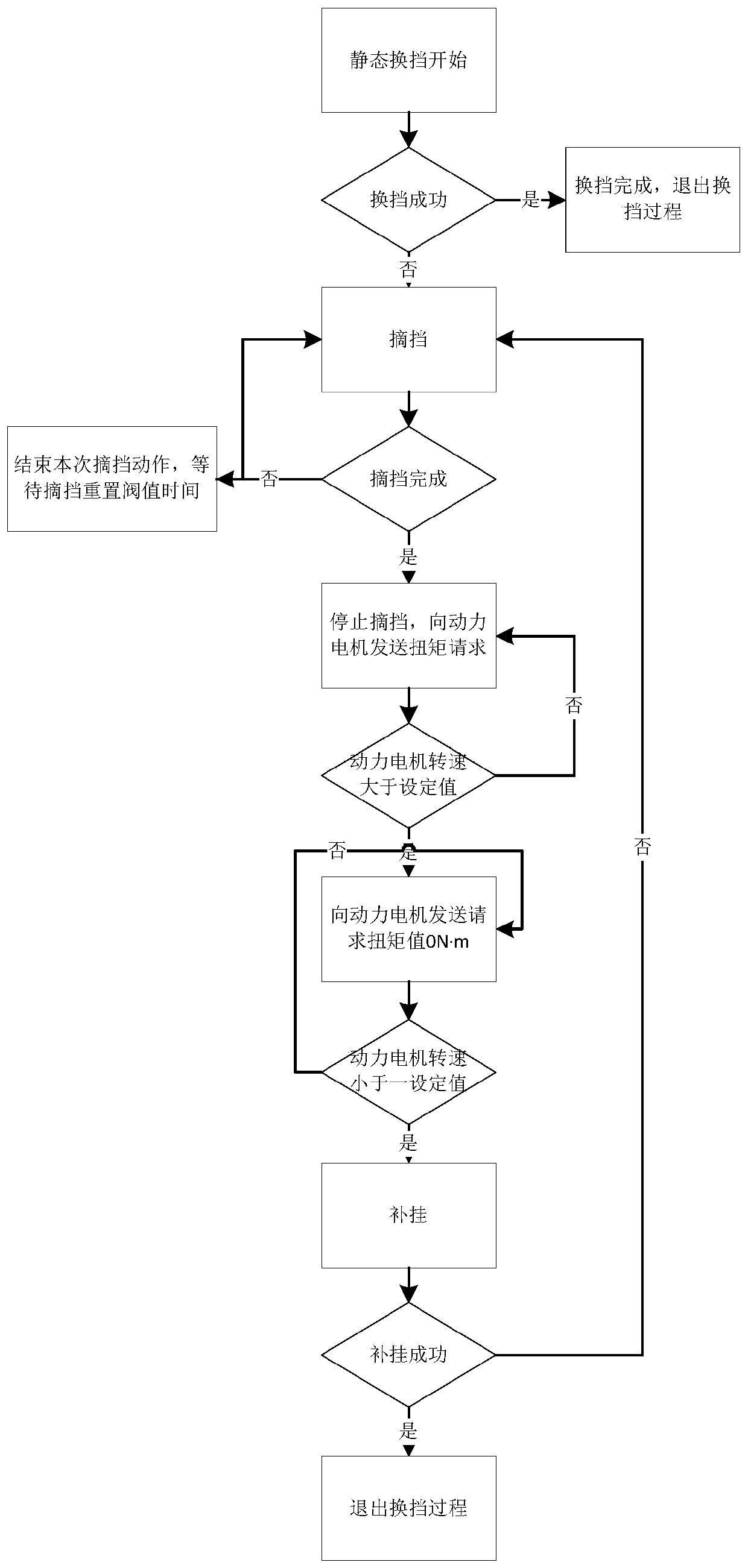

Embodiment 1

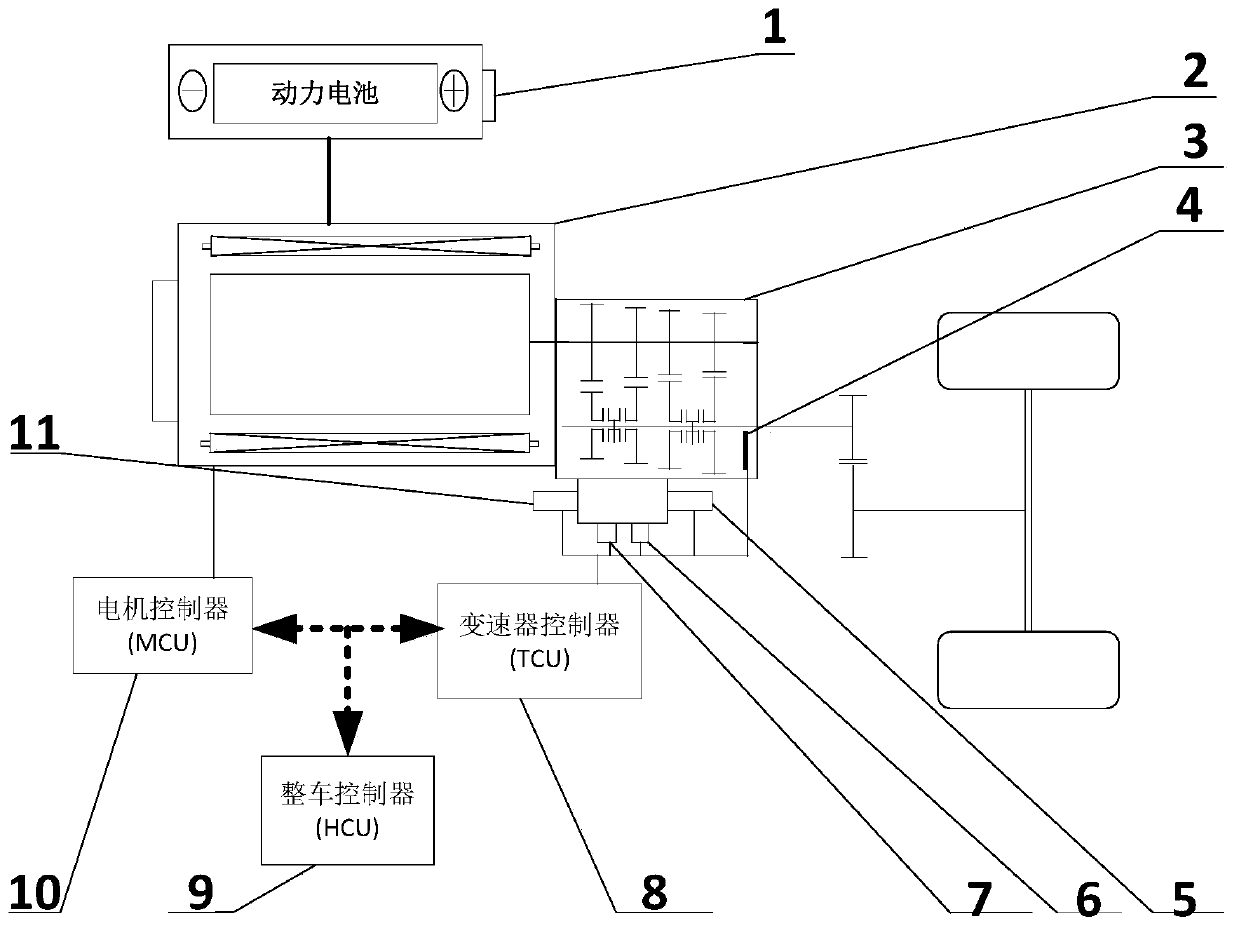

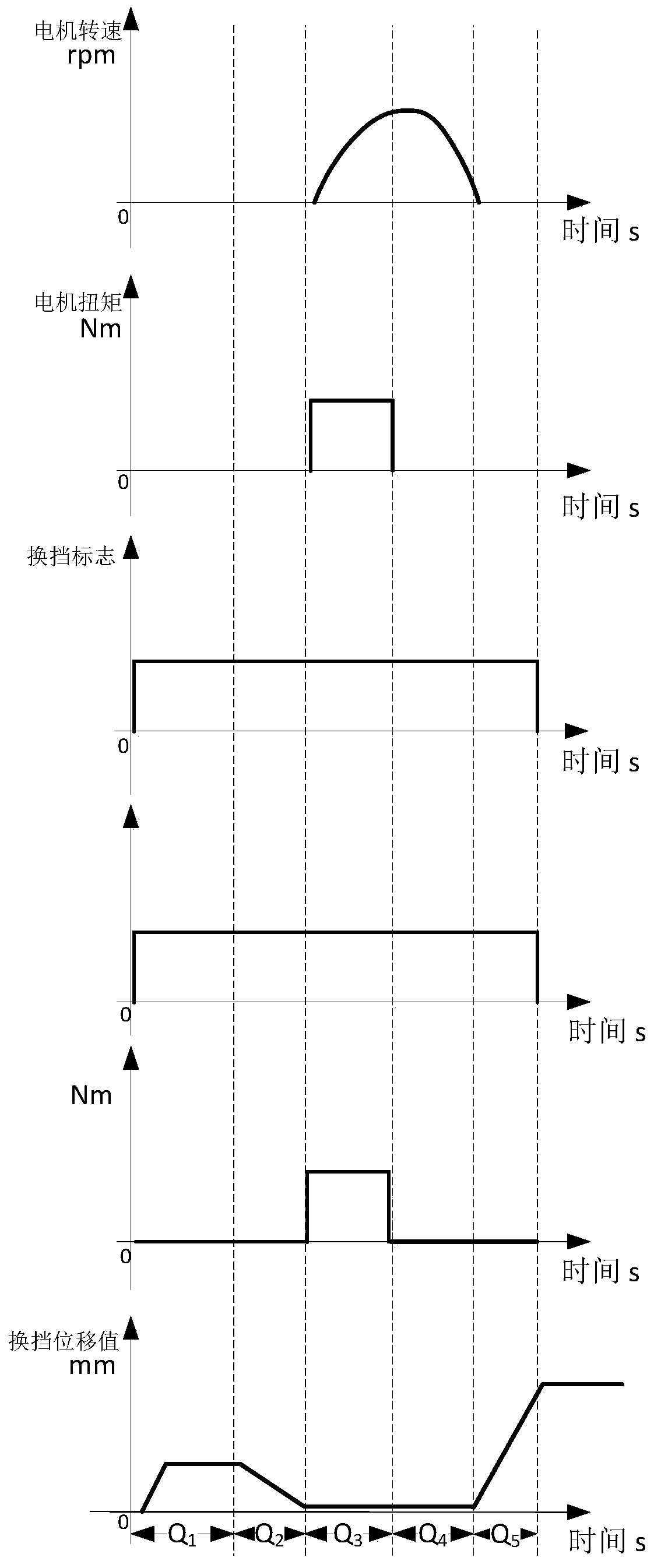

[0024] This embodiment provides a method for processing static shift failure of a mechanical automatic transmission of a pure electric vehicle, wherein the pure electric vehicle includes: a power battery 1, a power motor 2, a transmission 3, an output shaft speed sensor 4, and a shift execution Gear motor 5, shift position sensor 6, gear selection position sensor 7, transmission controller (TCU) 8, vehicle controller (HCU) 9, motor controller (MCU) 10 and gear selection actuator motor 11.

[0025] The power battery is used to provide electric energy to the power motor, so that the power motor rotates; the power motor is connected to the input shaft of the transmission through a spline drive without a clutch, and the output shaft of the transmission is connected to the final reduction gear to pass through the main reduction gear. The reduction gear drives the wheels to rotate, wherein the speed reducer is composed of 4 gears, and there is no shift synchronizer.

[0026] The out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com