Method for processing output end tank of double-power output engine

A technology of engine output and dual power output, which is applied to the engine frame, transmission box, supporting machine, etc., can solve the problems of fast gear wear, difficult clamping, and maintenance difficulties, and achieve long service life, low rotation noise, and meshing smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

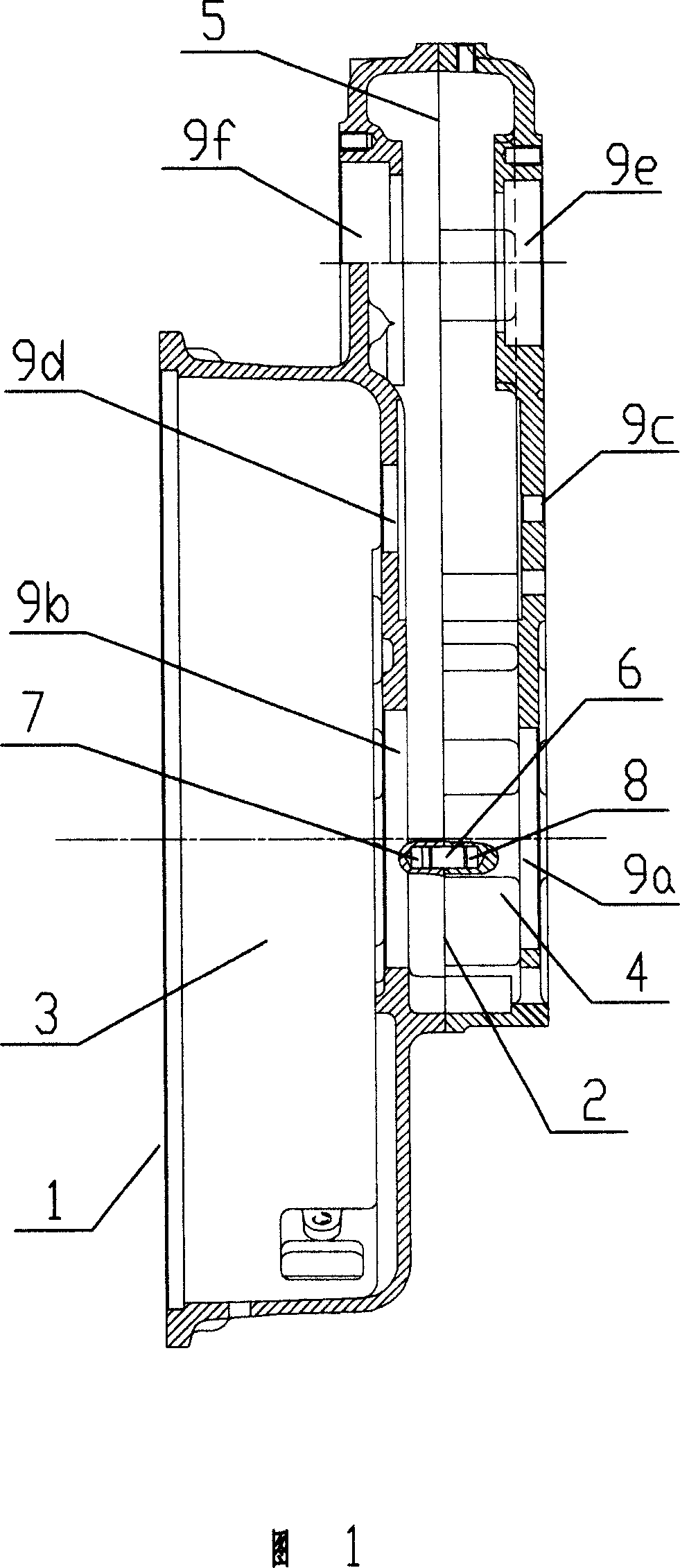

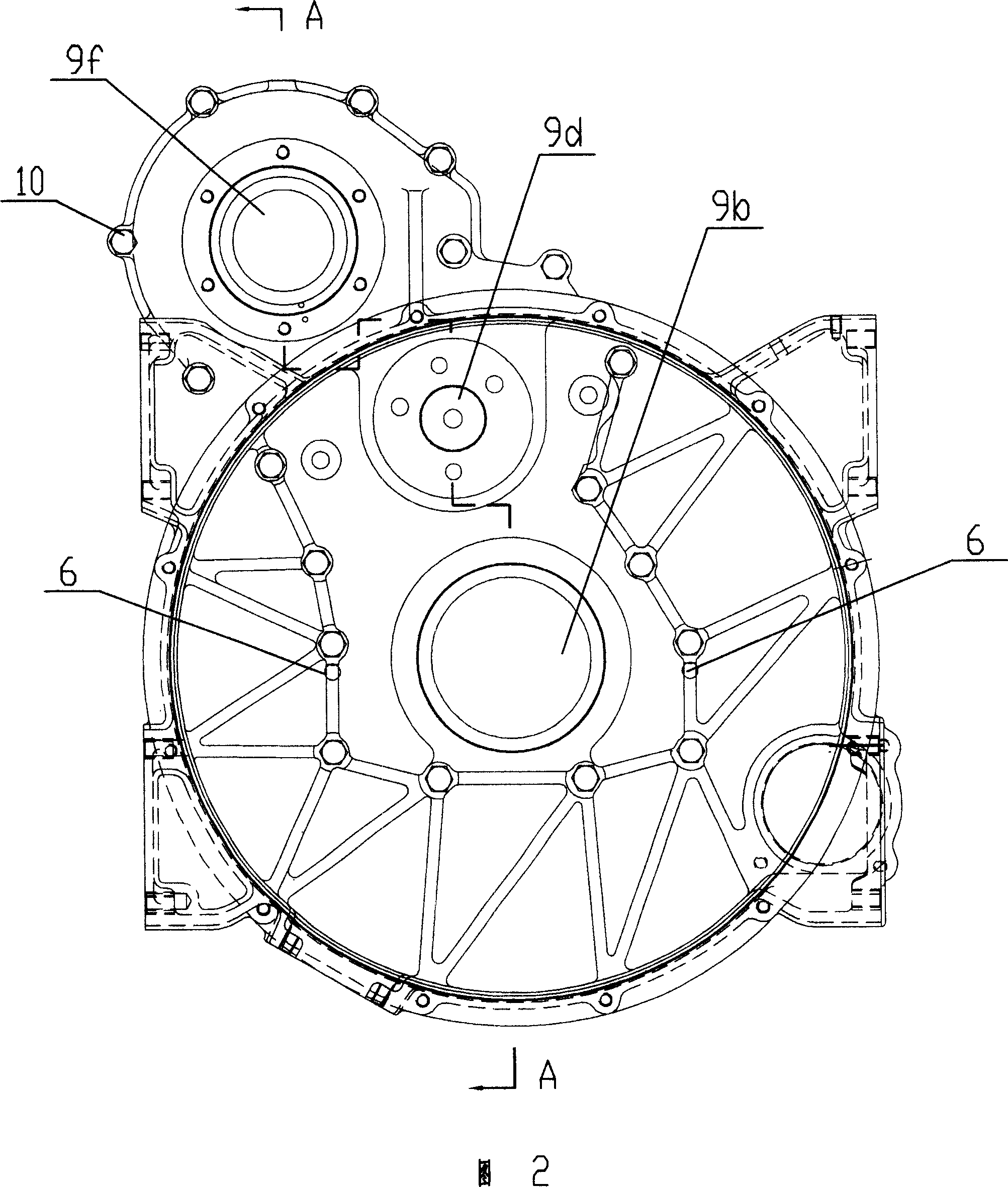

[0014] As shown in Figure 1 and Figure 2, the processing method of the output end casing of the dual power output engine includes the following steps:

[0015] The first step is to process the outer end surface 1 and the inner end surface 2 of the flywheel housing, process the connecting hole between the inner end surface 2 of the flywheel housing and the rear box body 4, and process the positioning pin hole 7 on the inner end surface 2 of the flywheel housing; process the rear box body 4 and the flywheel housing The joint surface 5 and the connection hole of the inner end surface 2 are processed on the joint surface 5 of the rear box body 4 and the inner end surface 2 of the flywheel housing 8;

[0016] The second step is to fix the flywheel housing on the special fixture for the flywheel housing, position the rear box body 4 and the flywheel housing 3 through the positioning pin 6, and then fix the rear box body 4 on the inner end surface 2 of the flywheel housing 3 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com