Monocrystal diamond clamp for self-rotating polishing machine and clamping method thereof

A single crystal diamond, grinding and polishing machine technology, applied in the field of diamond polishing, can solve the problems of clamping device clamping, cumbersome disassembly steps, poor clamping firmness, etc., achieves firm, stable and reliable clamping, simple and convenient installation and disassembly, and improved The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

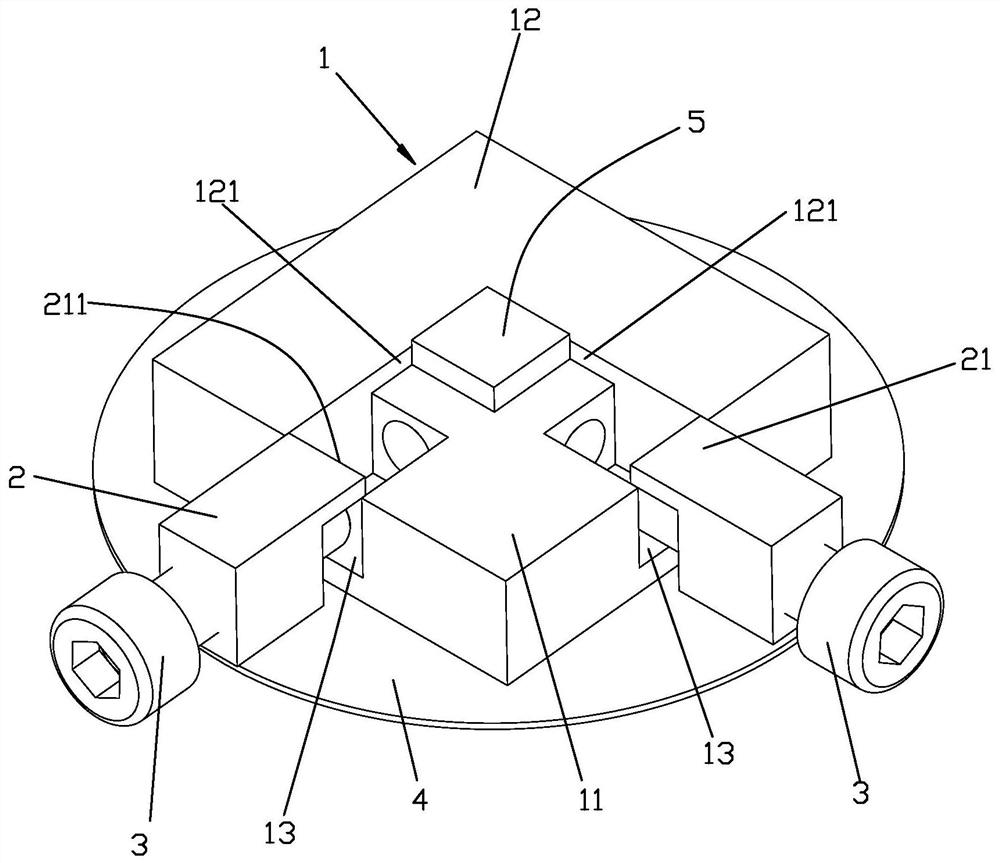

[0026] Please check figure 1 , a single crystal diamond fixture for a rotary grinding and polishing machine, including a body 1, two sliders 2, two adjustment parts 3 and a base 4; the top wall of the body 1 has a base wall 11 and is protrudingly arranged relative to the base wall 11 The boss 12 has two positioning walls 121 facing the base wall 11 and arranged vertically. The chute 13 on the side wall of the main body 1 and the two chute 13 are respectively arranged along the two positioning walls 121, and the two chute 13 are arranged vertically; Slidingly connected to the two slide grooves 13 and the protruding part 21 is located on the base wall 11, the end surface of the protruding part 21 forms a locking wall 211, and the locking walls 211 of the two sliders 2 and the two positioning walls 121 are arranged facing each other; The two adjustment parts 3 are respectively connected to the two sliders 2 and the body 1 so that the slider 2 can be slid and adjusted along the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com