Fastener head covered method and fastener head covered device

A zipper head and zipper technology, applied in the direction of sliding fastener elements, applications, fasteners, etc., can solve the problem of inability to set the zipper head, and achieve the effects of shortening delivery time, improving productivity and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

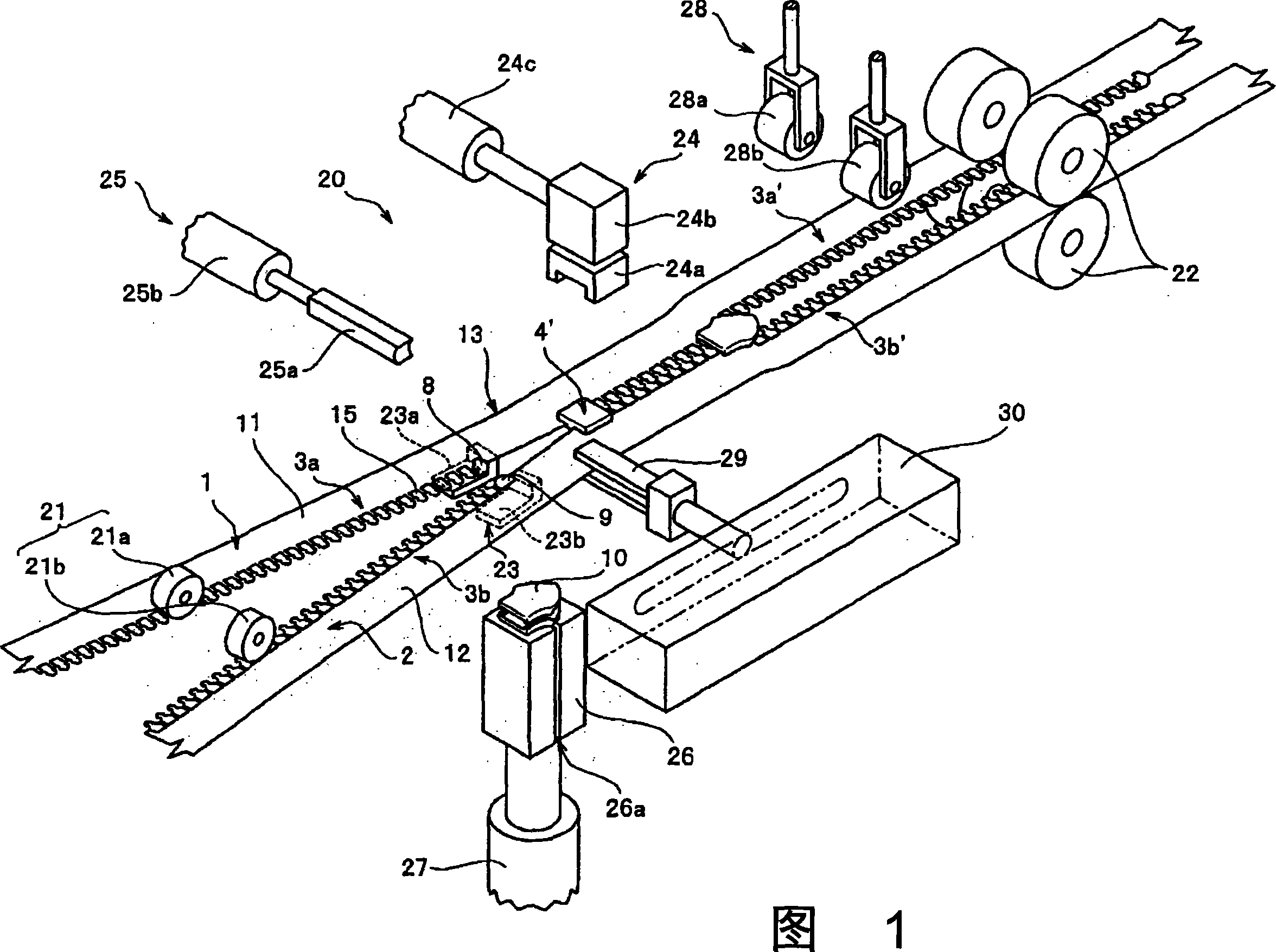

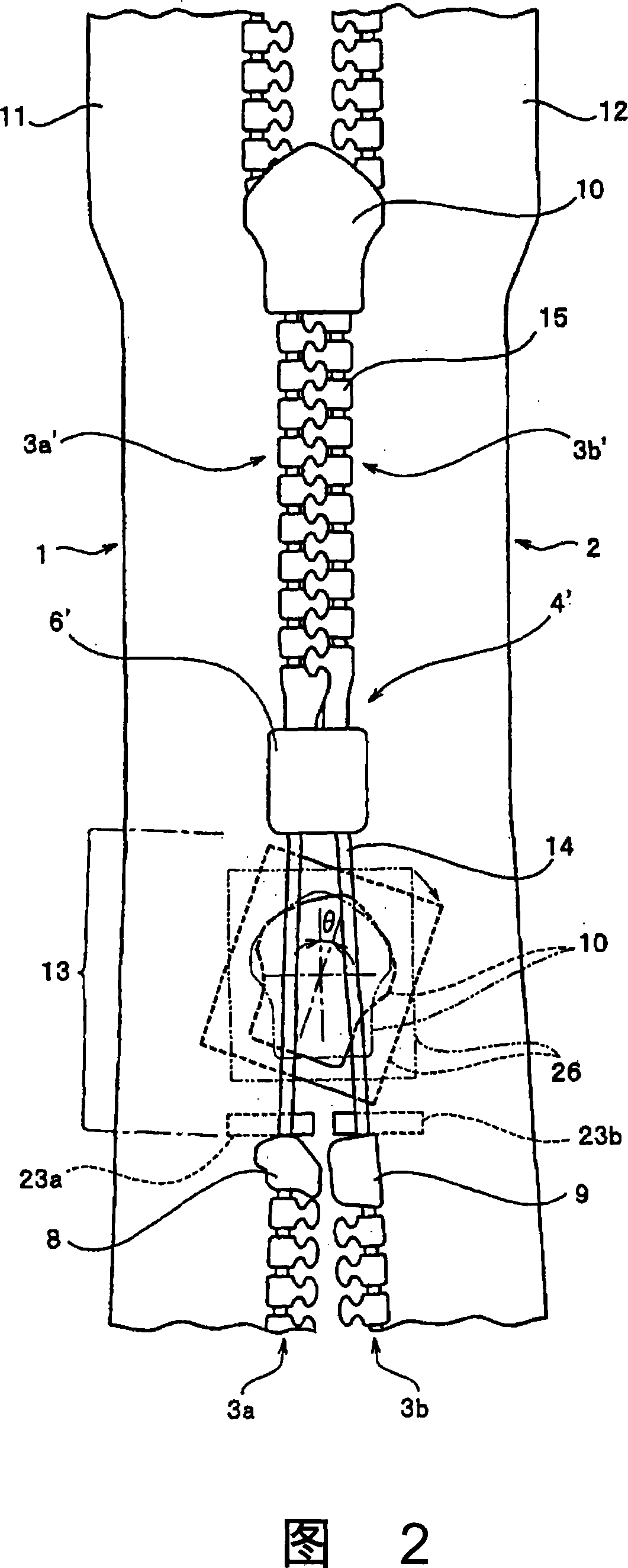

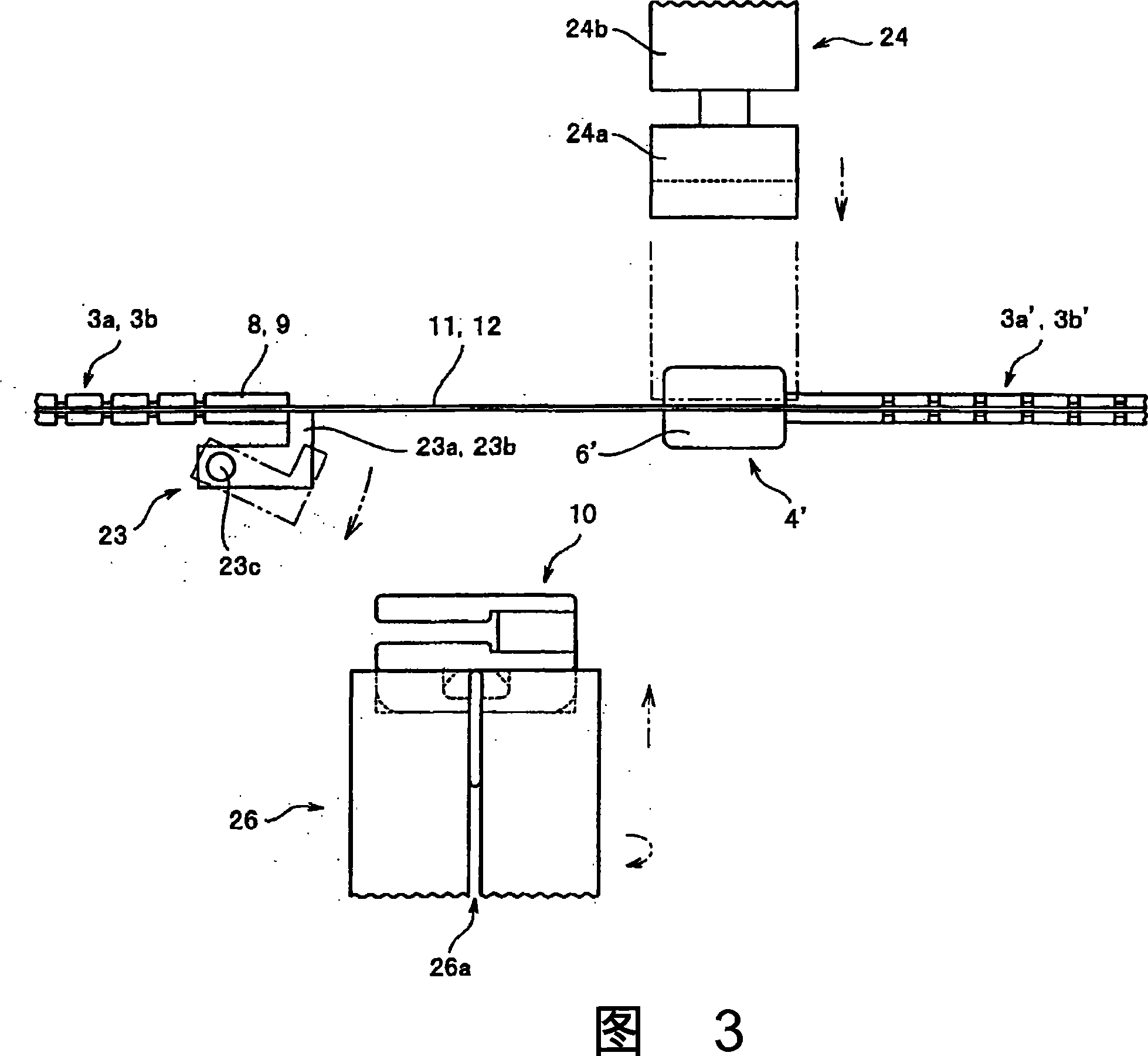

[0114] FIG. 1 is a schematic diagram schematically showing the configuration of a slide fastener slider installation device according to Embodiment 1 of the present invention. The slider attaching device 20 of the present Example 1 shown in this FIG. 1 has the following 1st - 5th means.

[0115] The first device includes: a transfer roller 22 for transferring the first zipper longitudinal strip 1 and the second zipper longitudinal strip 2; a detection part 21 for positioning the object chain tooth row 3a, 3b for the slide fastener head 10; The upper stops 8, 9 of 3a, 3b contact and reliably determine the positioning component 23 of the position of the chain tooth row 3a, 3b; for the chain tooth row 3a', 3b' formed on the chain tooth row 3a, 3b ahead of the chain tooth row 3a', 3b' The clamping part 24 that clamps the detachable bottom stopper 4'; The 1st cylinder 24c functioning as the 1st moving member which moves horizontally by predetermined distance in the direction ortho...

Embodiment 2

[0160] The zipper puller fitting device and the fitting method according to Embodiment 2 of the present invention will be described below. FIG. 17 is a schematic diagram schematically showing the configuration of a slider attaching device according to the second embodiment. In the description of the second embodiment and the referenced drawings, the components having the same configuration as those already described in the first embodiment are marked with the same reference numerals, and the description of the components will be omitted because they are represented by the same reference numerals.

[0161] The slider attaching device 40 of this Example 2 has the following 1st - 5th means. In this second embodiment, the first, second, fourth and fifth devices are substantially the same as the zipper puller setting device 20 in the above-mentioned embodiment 1.

[0162] That is, the first device includes: a transfer roller 22 for transferring the first and second zipper longitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com