Treatment system and treatment method of chlorosilane slurry raffinate

A treatment method and technology for a treatment system are applied in the field of treatment systems for chlorosilane slurry residues, and can solve problems such as increased discharge of slurry residues.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

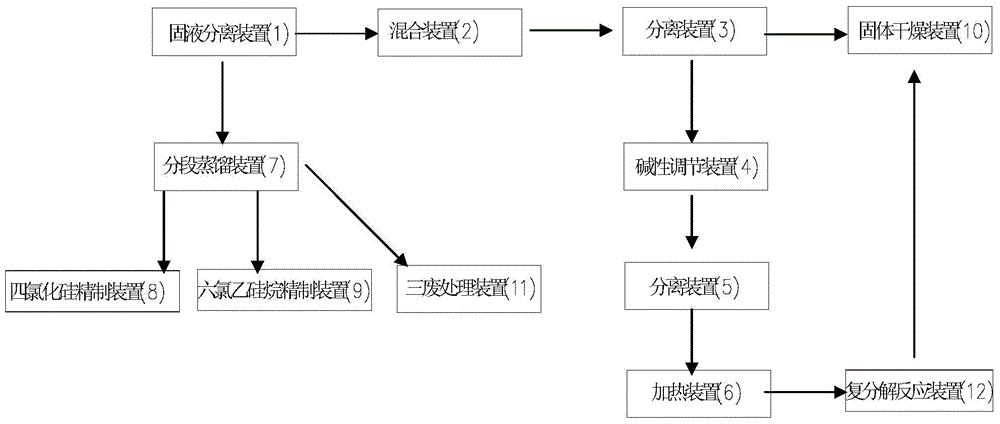

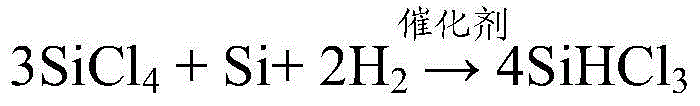

Method used

Image

Examples

Embodiment 1

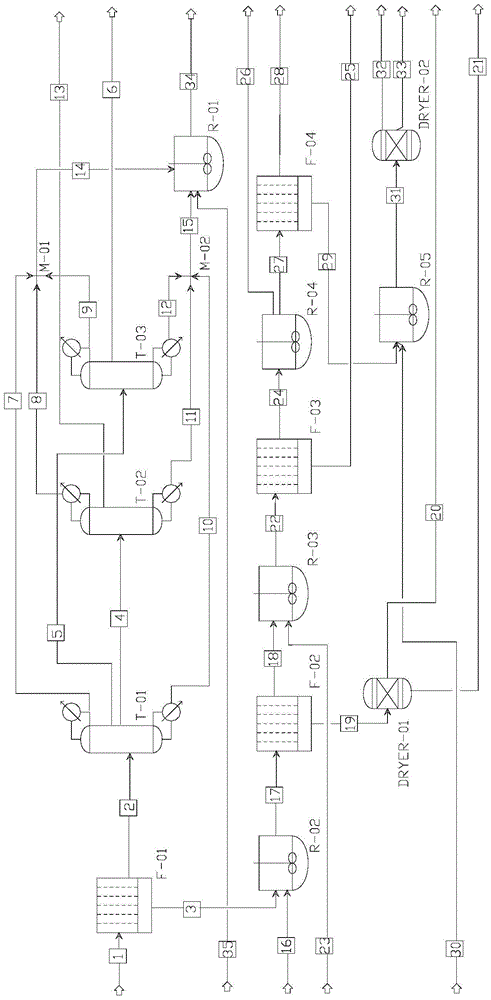

[0042] The main device system and flow diagram used are as follows: figure 2 shown. Among them: F-01~F-04 are filter devices. T01 is a chlorosilane distillation unit; T-02 is a silicon tetrachloride distillation unit; T-03 is a dichlorodisilane distillation unit. R-01 is a chlorosilane waste gas and residual liquid hydrolysis device; R-02 is a metal chloride dissolving device; R-03 is a ammonia water deposition Fe 3+ and Al 3+ ions; R-04 is heated to discharge the ammonia gas in the ammoniacal copper ions, depositing Cu(OH) 2 ; R-05 is hydrochloric acid and Cu Cu(OH) 2 metathesis reactor. M-01 is a non-condensable gas mixer; M-02 is a raffinate mixer. DRYER-01 is a silicon powder drying device; DRYER-02 is a CuCl 2 Drying device; 1 is chlorosilane slurry residue; 2 is liquid chlorosilane mixture; 3 is silicon powder and metal chloride; 4 is crude silicon tetrachloride; 5 is crude hexachlorodisilane; 6 is refined hexachloroethyl Silane; 13 is refined silicon tetrachlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com