System for producing silane, monochlorosilane, dichlorosilane and hexachlorodisilane

A technology of hexachlorodisilane and monochlorosilane, applied in the field of chemical synthesis, can solve the problems of limited development, no dichlorosilane and hexachlorodisilane, low selectivity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

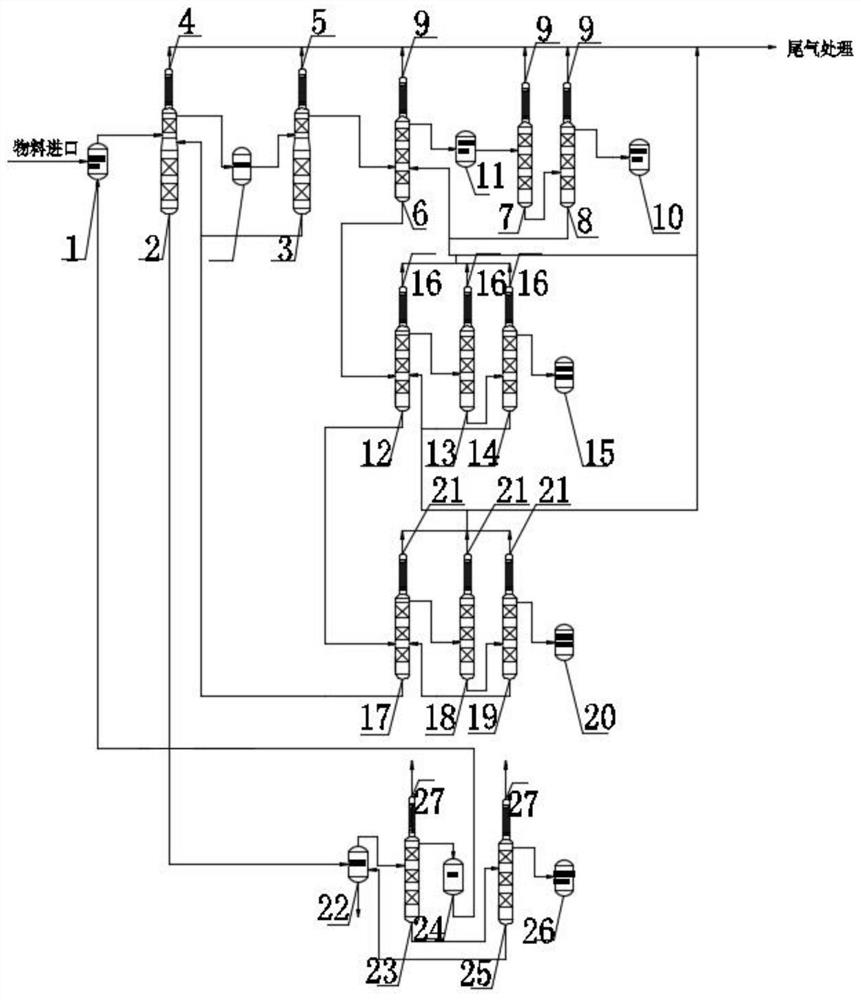

[0039] A system for producing silane, monochlorosilane, dichlorosilane and hexachlorodisilane, comprising: raw material synthesis system, silane synthesis system, monochlorosilane synthesis system, dichlorosilane synthesis system and hexachlorodisilane synthesis system; wherein , raw material synthesis system comprises hydrogenation system 1, disproportionation tower one 2, disproportionation tower two 3, condenser one 4 and condenser two 5; Wherein, condenser one 4 is fixed on the top of disproportionation tower one 2, and disproportionation tower one 2 Connected; condenser two 5 is fixed on the top of disproportionation tower two 3, and is communicated with disproportionation tower two 3; The inlet of hydrogenation system 1 is communicated with hexachlorodisilane synthesis system; Top outlet is communicated with the inlet of disproportionation tower one 2; Disproportionation tower The top outlet of disproportionation tower 2 is connected with the inlet of disproportionation t...

Embodiment 2

[0050] A method for producing silane, monochlorosilane, dichlorosilane and hexachlorodisilane, utilizes the system of embodiment 1 to produce, and the process is as follows:

[0051] 1) Send the raw materials hydrogen, silicon powder, and silicon tetrachloride into the hydrogenation system, and catalyze the synthesis of trichlorosilane through a catalyst; the reaction temperature is controlled at 100-800°C, the reaction pressure is controlled at 0.1-2MPa, and the catalyst is a transition metal salt , may be one of nickel, iron, copper, cobalt and zinc;

[0052] 2) Silicon trichloride enters the disproportionation tower 1 for disproportionation reaction, and is catalyzed by the disproportionation tower 1 catalyst to generate TCS and DCS. The mixed gas generated is rectified by the disproportionation tower 1. The silane enters the vaporizer from the tower kettle for separation; the light fraction enters the buffer tank from the upper part of the disproportionation tower one to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com