Method for collection of hexachlorodisilane and plant for the method

A technology of hexachlorodisilane and recovery method, applied in halosilanes, separation methods, chemical instruments and methods, etc., can solve problems such as hindering continuous operation of equipment, pipe blockage, etc., so as to improve operation efficiency and economic efficiency, and prevent blockage. , the effect of enhancing cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

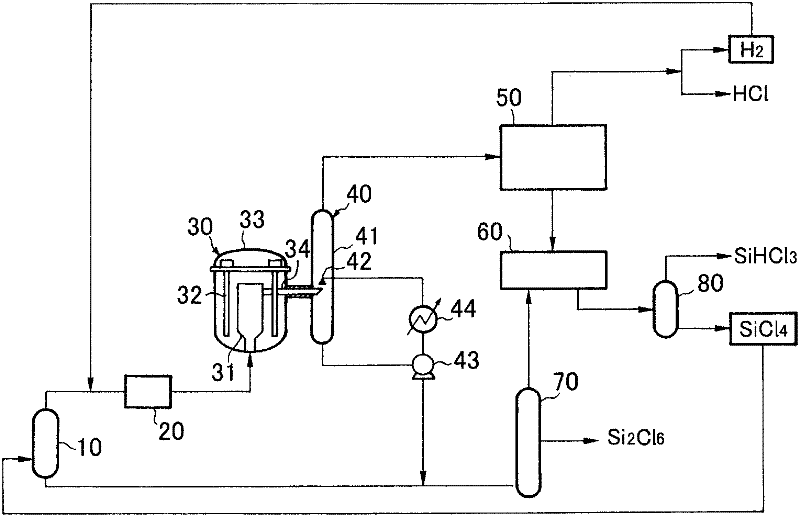

[0107] use figure 1 The apparatus shown produces trichlorosilane and recovers hexachlorodisilane as a by-product.

[0108] The evaporator was adjusted so that the internal temperature reached 100° C. and the internal pressure reached 0.1 MPa (absolute pressure), and tetrachlorosilane was continuously evaporated.

[0109] Vaporized tetrachlorosilane and hydrogen were mixed at a molar ratio of 1:2, preheated to 600° C. by a preheater, and continuously supplied to the reaction furnace at a flow rate of 27 moles / hour.

[0110] The reaction furnace was heated so that the center temperature of the reaction vessel accommodated therein was maintained at 1300°C.

[0111] The reaction generated gas generated in the reaction furnace is exported to the quench tower, and under the conditions of 0.1l / min and spray pressure at the spray rate, the mixture of trichlorosilane and tetrachlorosilane (moles) is sprayed in the quench tower in the quench tower. Ratio = 85:15) composed of cooling l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com