Doped nitride film, doped oxide film and other doped films

a technology of oxide film and nitride film, which is applied in the field of films, can solve the problems of difficult to modulate stress to a large extent without comprising film quality, many low temperature precursors have been investigated, and achieve the effect of increasing the deposition ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

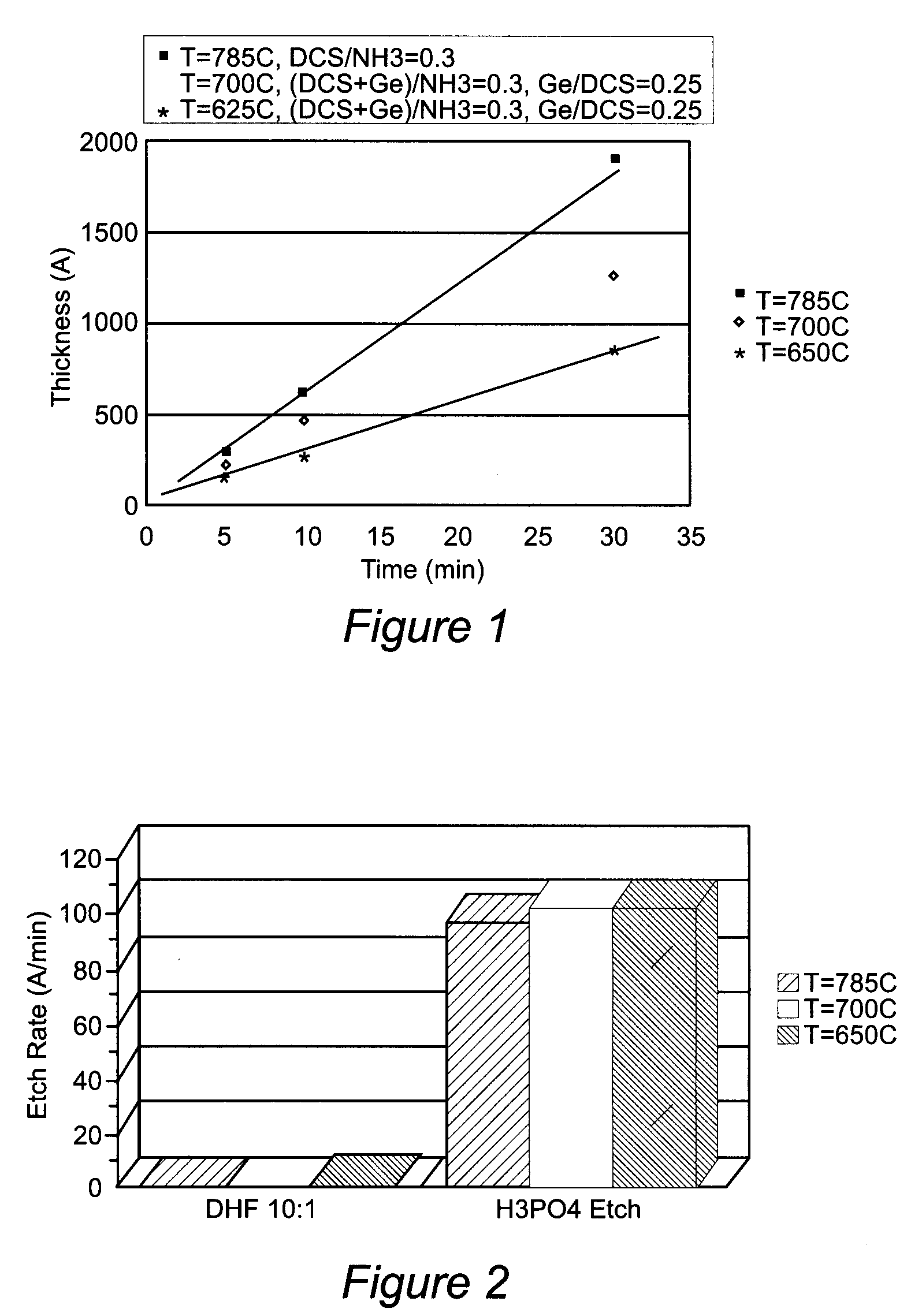

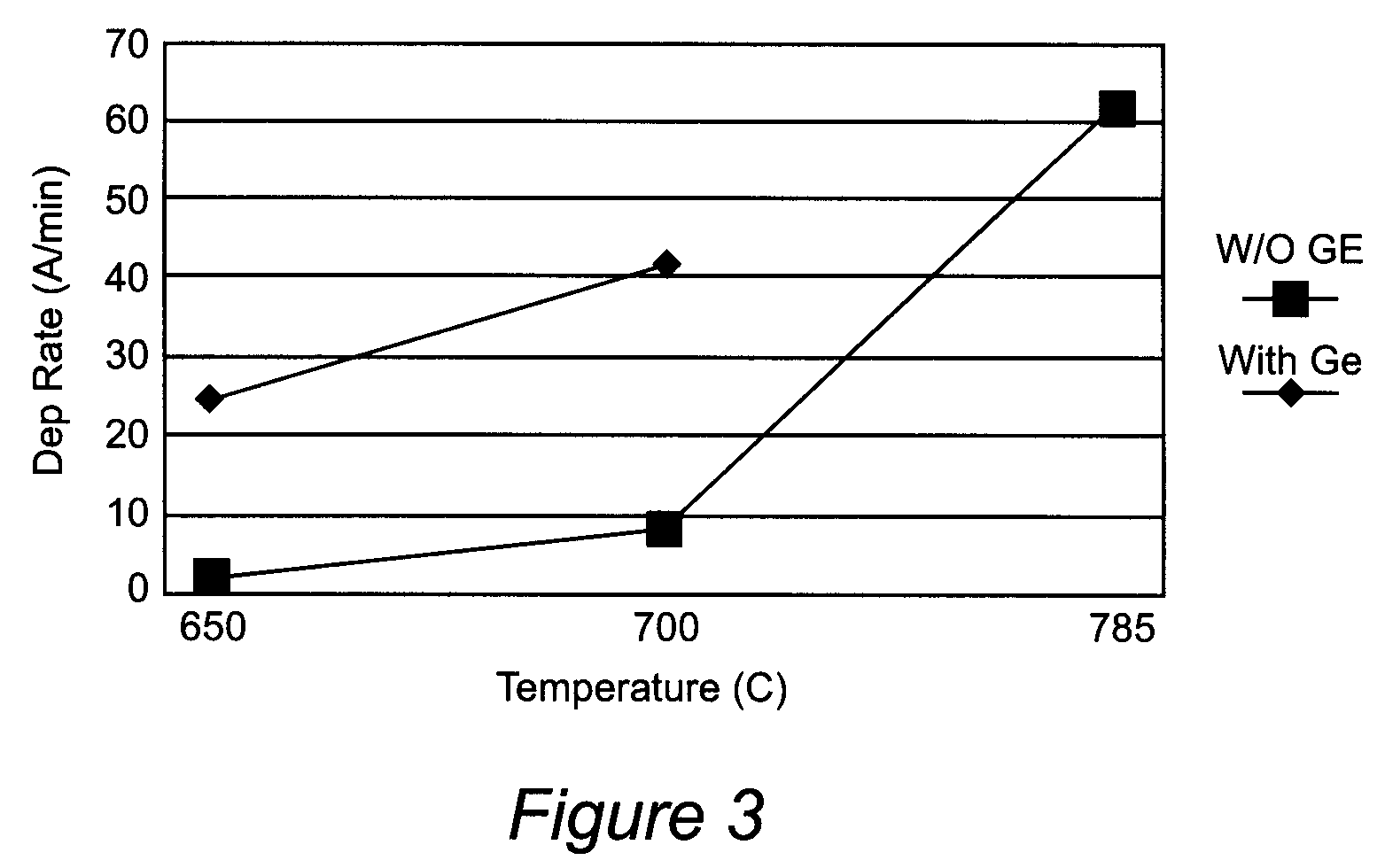

[0043] In an LPCVD furnace, GEH4 was added to a mixture of DCS and NH3 at two different temperatures, 700 and 650° C. respectively. A standard silicon nitride film was also deposited at 785° C. as a control. Two germanium-doped silicon nitride films and one standard silicon nitride film were thus deposited. The results are summarized in the charts which are FIGS. 1, 2 and 3.

[0044] In FIG. 1, the top plot is for the film deposited at 785° C., with DCS / NH3=0.3 The middle plot in FIG. 1 is for the film deposited at 700° C., with (DCS+Ge) / NH3=0.3, Ge / DCS=0.25. The bottom plot in FIG. 1 is for the film deposited at 650° C., with the same ratios as for the film deposited at 700° C.

[0045] From FIG. 3, it is clear that by adding GeH4 to the process gas, a significant increase in the deposition rate has been achieved. Also, the germanium-doped films of this Example 1 have a similar property (determined by wet etch rate) to the standard high temperature films.

[0046] The addition of germane...

example 2

[0047] Importantly, the present inventors have recognized that stress in a film may be modified by germanium addition during nitride film formation. There may be considered the following results, both for silicon substrates: (i) for a Si—N film, stress of 4 E9 Dyne / cm2 (compressive); (ii) for a SiGe—N film, stress of 8.2 E9 Dyne / cm (tensile).

[0048] As the above data shows, there is almost an order of magnitude stress difference between a conventional silicon nitride film and an inventive germanium-doped silicon nitride film.

[0049] It will be appreciated that the advantages of the present invention with regard to deposition rate and / or stress tuning are not limited to nitride films, and may be applicable for oxide films (such as silicon oxide films, etc.) and other films, such as other amorphous films.

example 3

[0050] Ge was added to a mixture of silane and ammonia, forming a Ge-doped Si nitride film. The deposition rate was increased for the germane process, compared to an equivalent no-germane process. For the no-Ge processs, the stress of the produced film was 0.4 GPa (compressive). For the inventive process using Ge, the stress was 0.8 GPa (tensile). Thus, the use of Ge according to the invention achieved a change in stress of 1.2 GPa, which was a substantial improvement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com