Surface installation inductor

A surface mount type, inductor technology, applied in the direction of transformer/inductor core, transformer/inductor coil/winding/connection, etc., can solve the problems of equipment influence, leakage magnetic flux, etc., to improve inductance value and position accuracy , Workability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

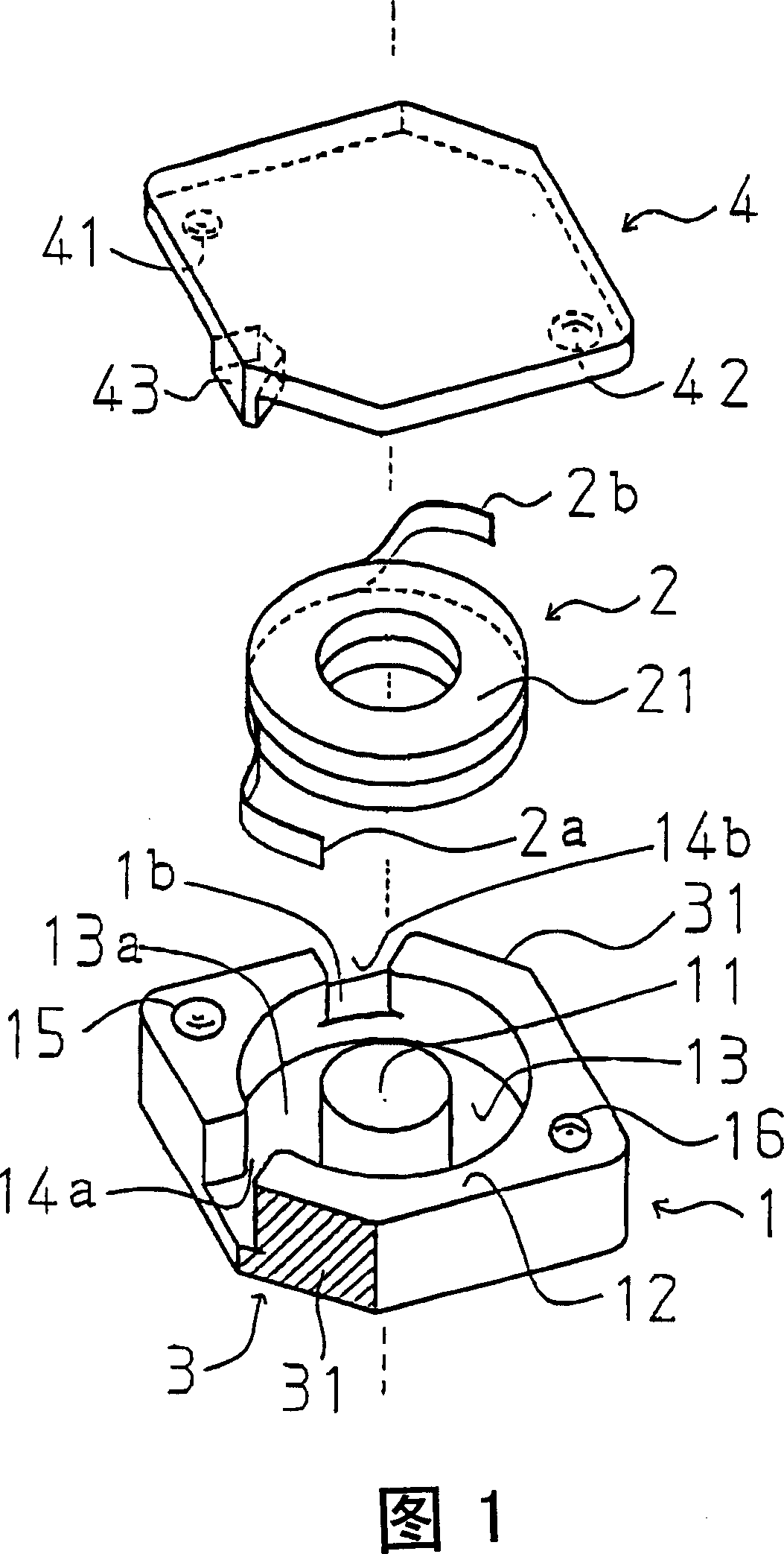

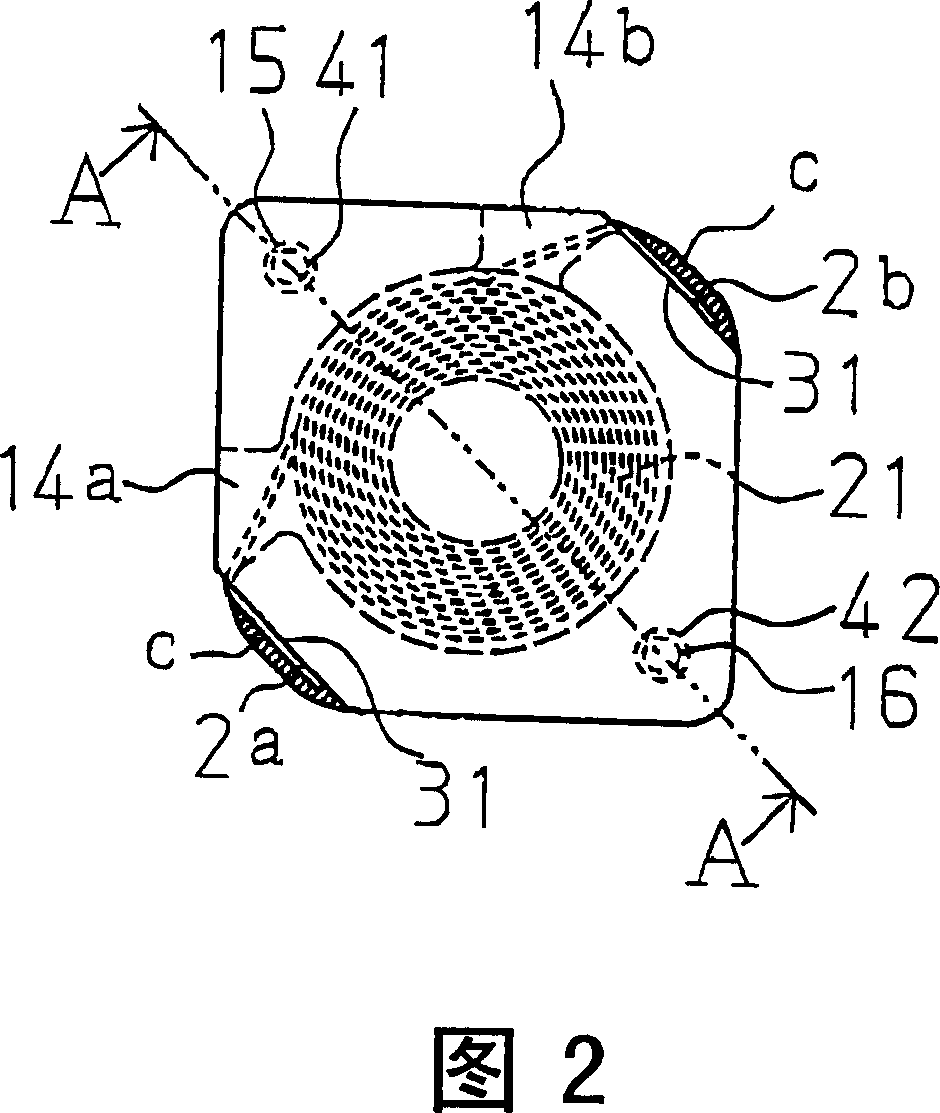

[0036] As shown in FIGS. 1 to 4 , the surface-mounted inductor of this embodiment is composed of the following parts: a cylindrical core 1 whose bottom surface is approximately square, and has a cylindrical magnetic core part 11 and an outer wall 12 in the center; The coil 2 is fitted on the magnetic core part 11 of the cylindrical core 1; the electrode 3 is arranged on the outer peripheral surface of the cylindrical core 1 and is electrically connected with the flat coil 2; The barrel core 1 is closed.

[0037] The cylindrical core 1 is made of a ferrite material, and has a substantially square bottom surface, a columnar core portion 11 at the center, and an outer wall 12 integrally erected with the bottom surface. Between the core part 11 and the outer wall 12, a coil housing part 13 for housing the flat coil 2 is provided. Moreover, the coil housing part 13 has the bottom surface part 13a which arrange|positions the bottom surface of the flat coil 2 wound.

[0038] In add...

no. 2 Embodiment approach

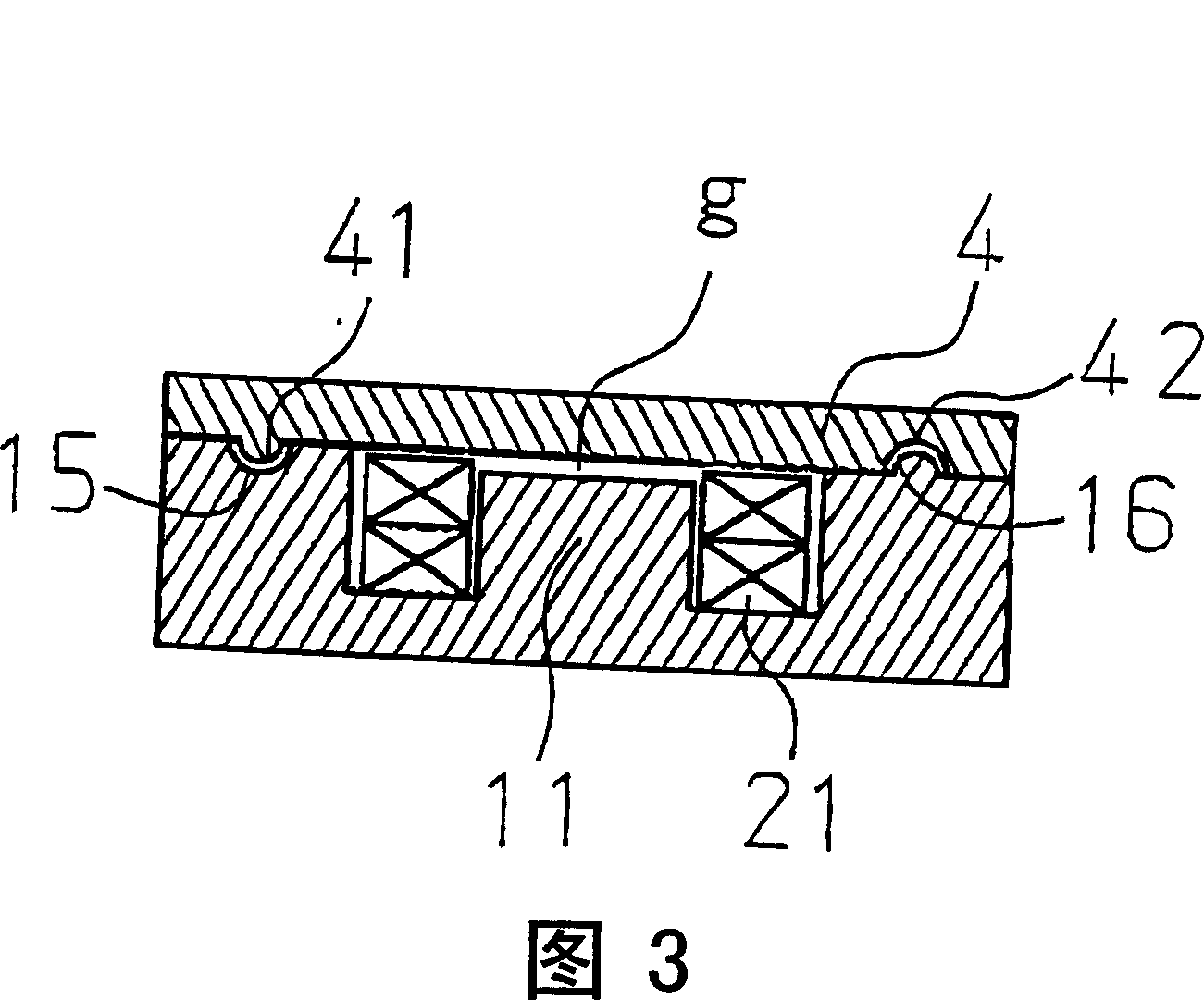

[0056] In the surface mount inductor of this embodiment, as shown in FIG. 5 , a magnetic core part is also provided on the cover core 4, and the height of the magnetic core part 11 of the cylindrical core 1 is made low so that it is in contact with the cover core. The magnetic core portion of 4 has a predetermined air gap g, and other configurations are the same as those of the first embodiment.

[0057] Alternatively, the magnetic core portion may be provided only on the cover core so that a predetermined air gap g is provided between the magnetic core portion and the bottom portion of the cylindrical core.

[0058] Owing to be the structure as above, so, as the effect of the present invention, owing to be provided with the cylindrical core 1 that has outer wall and the cap core 4 that closes the open end of this cylindrical core 1, so between the outer wall of this cylindrical core 1 and There is no gap between the cover cores 4, and when the cylindrical core 1 is viewed fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com