Coil component

A technology of coil components and wires, applied in transformer/inductor parts, electrical components, transformer/inductor coil/winding/connection, etc. Effects of Transform Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

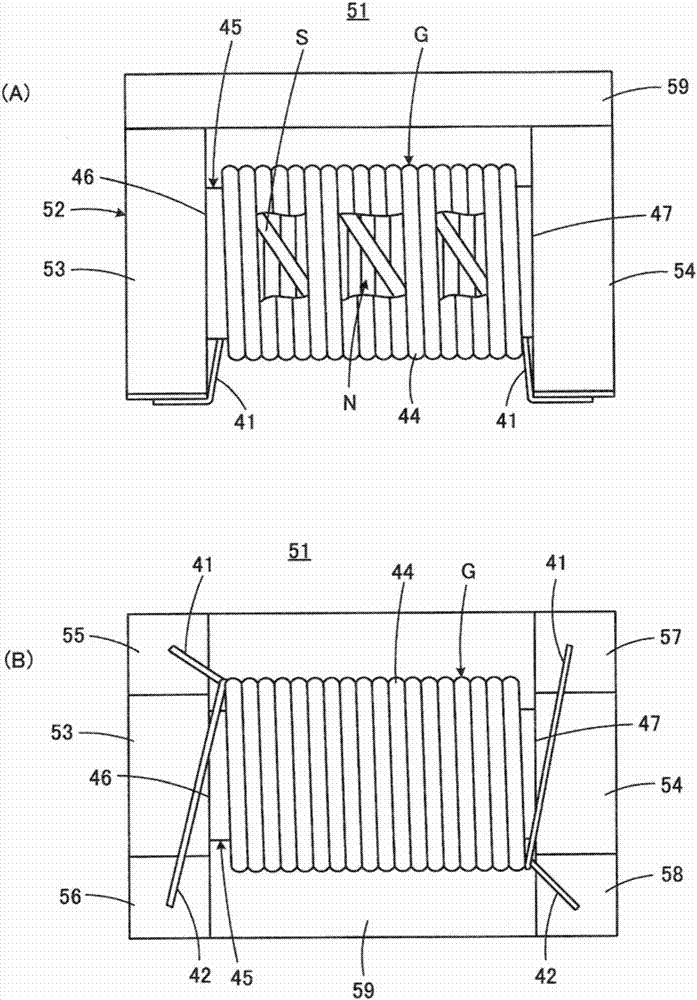

[0063] refer to figure 1 and figure 2 The common mode choke coil 51 as a coil component according to the first embodiment of the present invention will be described. In addition, in figure 1 and figure 2 , against the above Figure 17 ~ Figure 19 Elements corresponding to the elements shown are denoted by the same reference numerals.

[0064] The common mode choke coil 51 includes a drum-shaped core 52 and first and second wires 41 and 42 respectively constituting an inductor. exist figure 1 In the illustration, only the respective ends of the first and second wires 41, 42 are shown, and the middle part is schematically illustrated in a single wire state for reference. Figure 17 The wire assembly part 44 which consists of the 1st wire 41 and the 2nd wire 42 as mentioned above. The drum core 52 is made of an electrically insulating material, more specifically, a non-magnetic material such as aluminum, a magnetic material such as Ni—Zn-based ferrite, or resin. The ...

no. 2 approach

[0113] Next, refer to Figure 6 A common mode choke coil 51a according to a second embodiment of the present invention will be described. exist Figure 6 and later Figure 8 ~ Figure 15 in, right with figure 2 Components corresponding to the shown components are denoted by the same reference numerals, and repeated explanations are omitted.

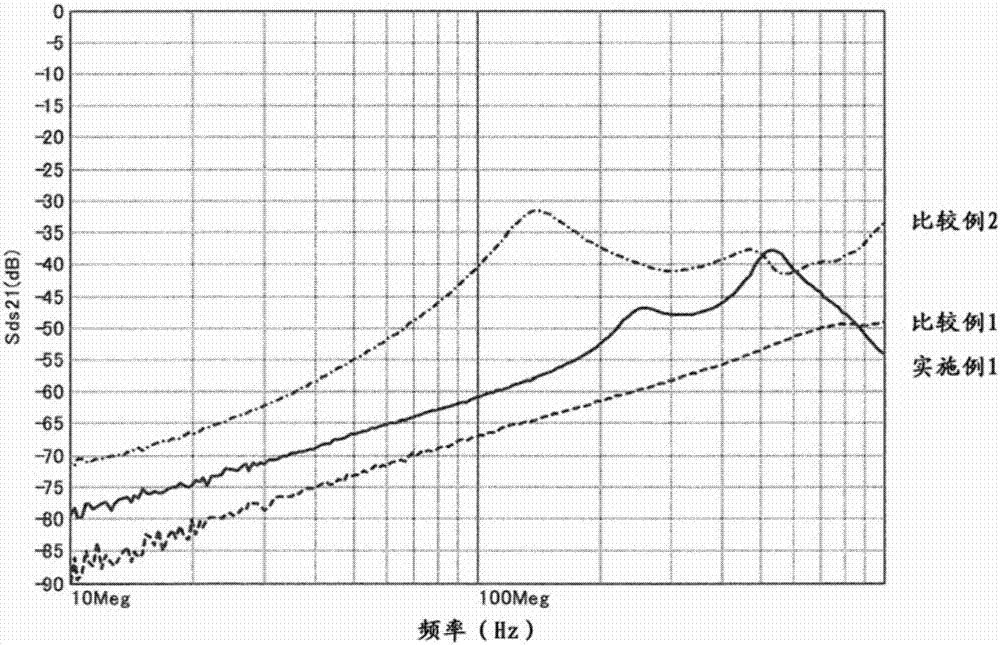

[0114] The common mode choke coil 51a has a larger number of turns of the wire assembly part 44 than the common mode choke coil 51 described above. That is, the number of turns is 37. In addition, in the common mode choke coil 51 , there are three outward transition portions S around the winding core portion 45 , but in the common mode choke coil 51 a, there are five outward transition portions S. Therefore, in the common mode choke coil 51a, five outer layer portions G are formed, more specifically, four first outer layer portions Ga and one second outer layer portion Gb are formed.

[0115] Regarding the common mode choke coil 51a...

no. 3 approach

[0123] Next, refer to Figure 8 The common mode choke coil 51b of the third embodiment of the present invention will be described.

[0124] Common mode choke coil 51b, for example with figure 2 Compared with the common mode choke coil 51 shown, although the number of turns of the wire assembly part 44 is the same, the numbers of the outward transition part S and the inward transition part T are larger.

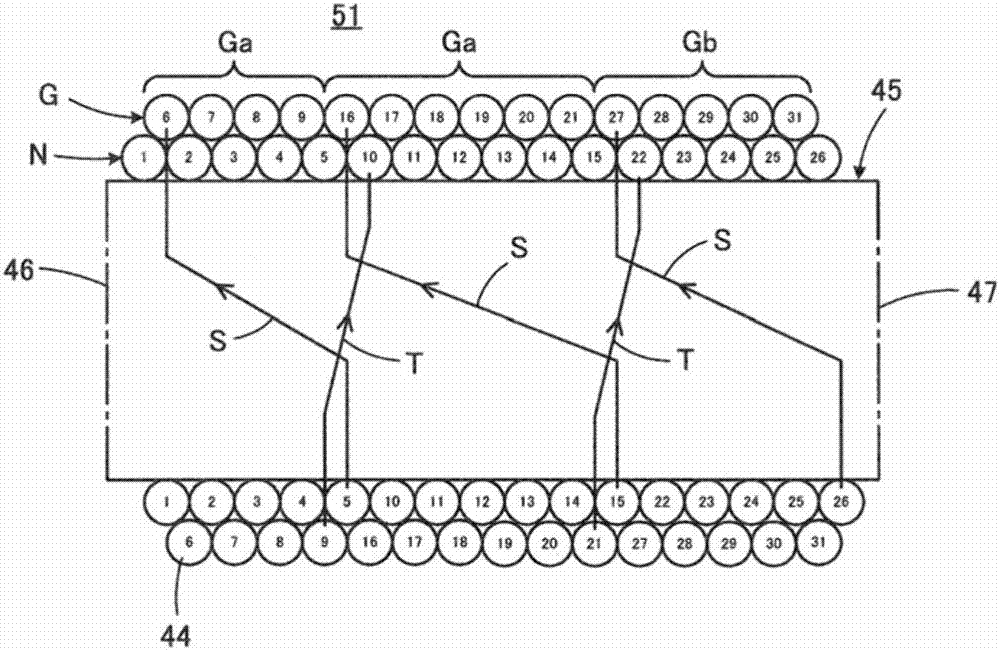

[0125] Regarding the common mode choke coil 51b, the winding form of the wire assembly part 44 will be described based on the number of turns of the wire assembly part 44 on the winding core part 45. First, the inner layer part N is composed of turns 1 to 2, and then , the transition part from turn 2 to turn 3 constitutes the outward transition part S, then, the first outer layer part Ga is formed by turn 3, and then the transition part from turn 3 to turn 4 constitutes the inward transition part T.

[0126] Next, an inner layer portion N is formed by turns 4-5, then an out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| inductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com