Binderless storage phosphor screen with needle shaped crystals

a technology of phosphor screen and needle crystal, which is applied in the direction of photosensitive material auxillary/base layer, coating, photographic process, etc., can solve the problem that the production method cannot be used to produce high-quality screens, and achieve the effect of low noise, high sharpness, and good compromise between the speed of the recording system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Preparation of the phosphor

[0048] CsBr:Eu screens were made via thermal vapour deposition of CsBr and EuOBr. To this aim, CsBr was mixed with EuOBr and placed in a container in a vacuum deposition chamber. The phosphor was deposited on a glass disk with a thickness of 1.5 mm and a diameter of 40 mm. The distance between the container and the substrate was 10 cm. During evaporation, the substrate was rotated at 12 rpm. The container with starting materials was heated to a temperature of 750.degree. C.

[0049] Before the start of the evaporation, the chamber was evacuated to a pressure of 4.10.sup.-5 mbar. During the evaporation process, Ar was introduced in the chamber.

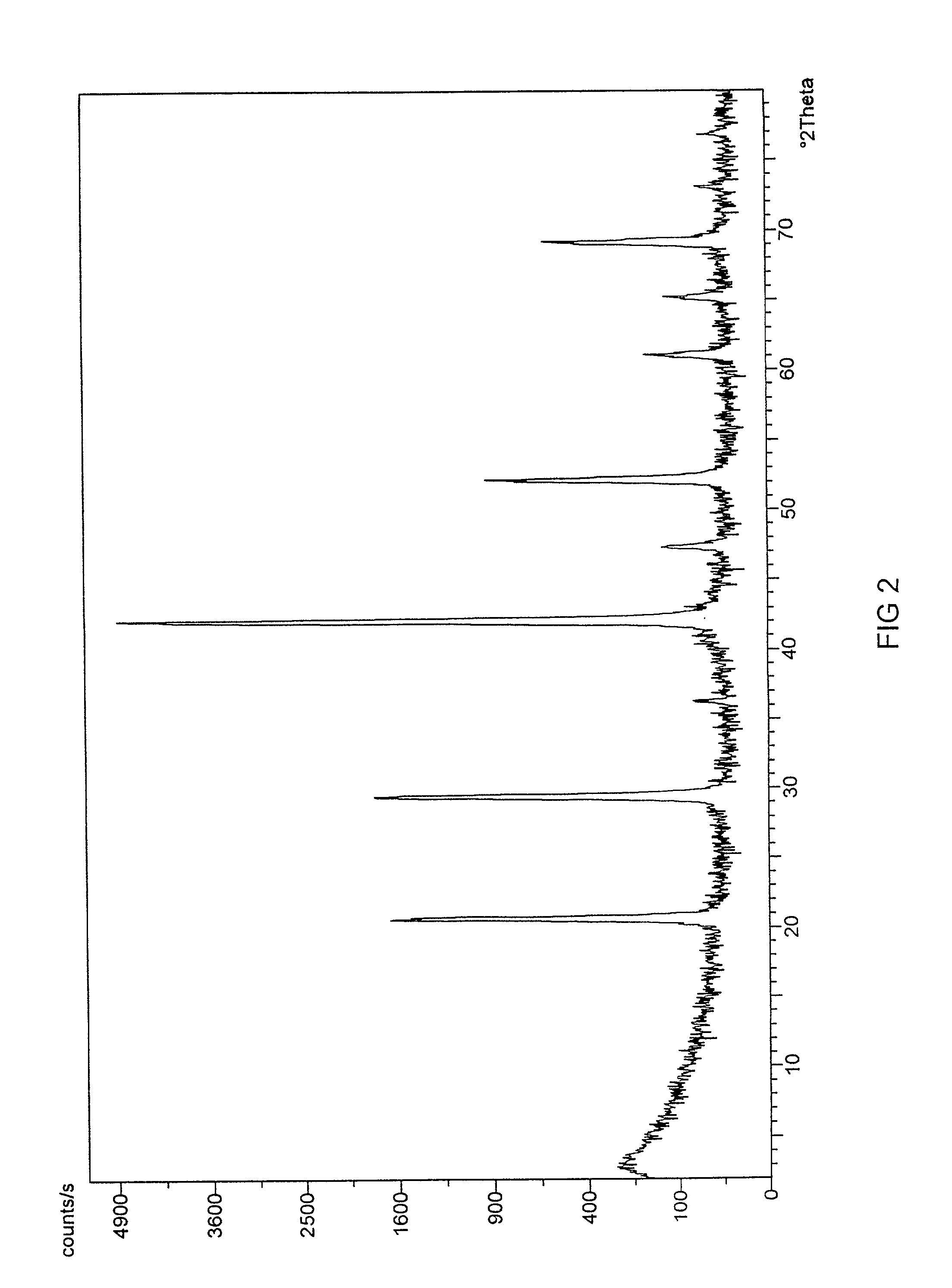

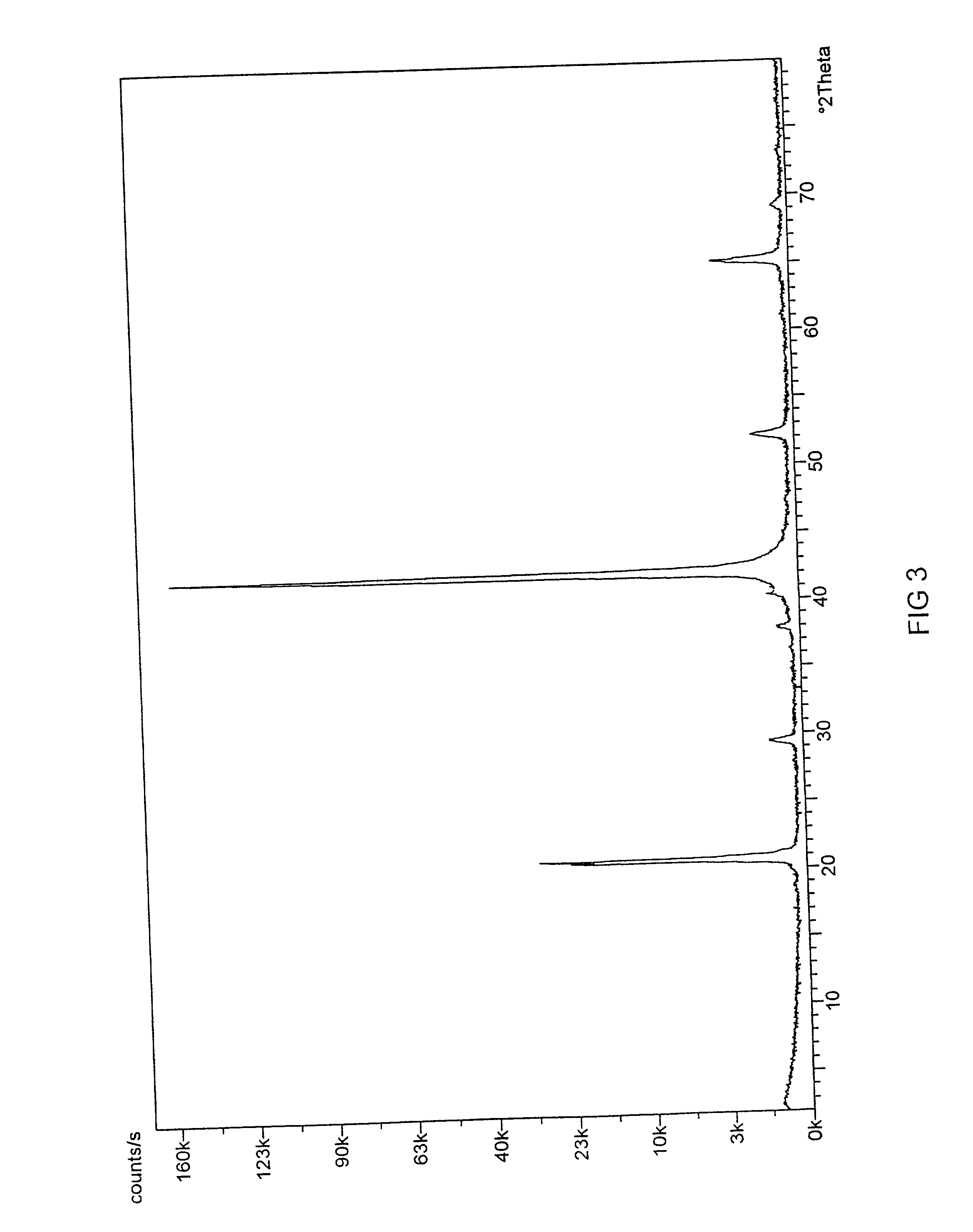

[0050] Variables in the deposition process were the substrate temperature and the Ar gas pressure. The different screens were produced under the conditions listed in Table 1. The Eu-concentration in the evaporated screens was measured with X-ray fluorescence and was of the order of 800 ppm.

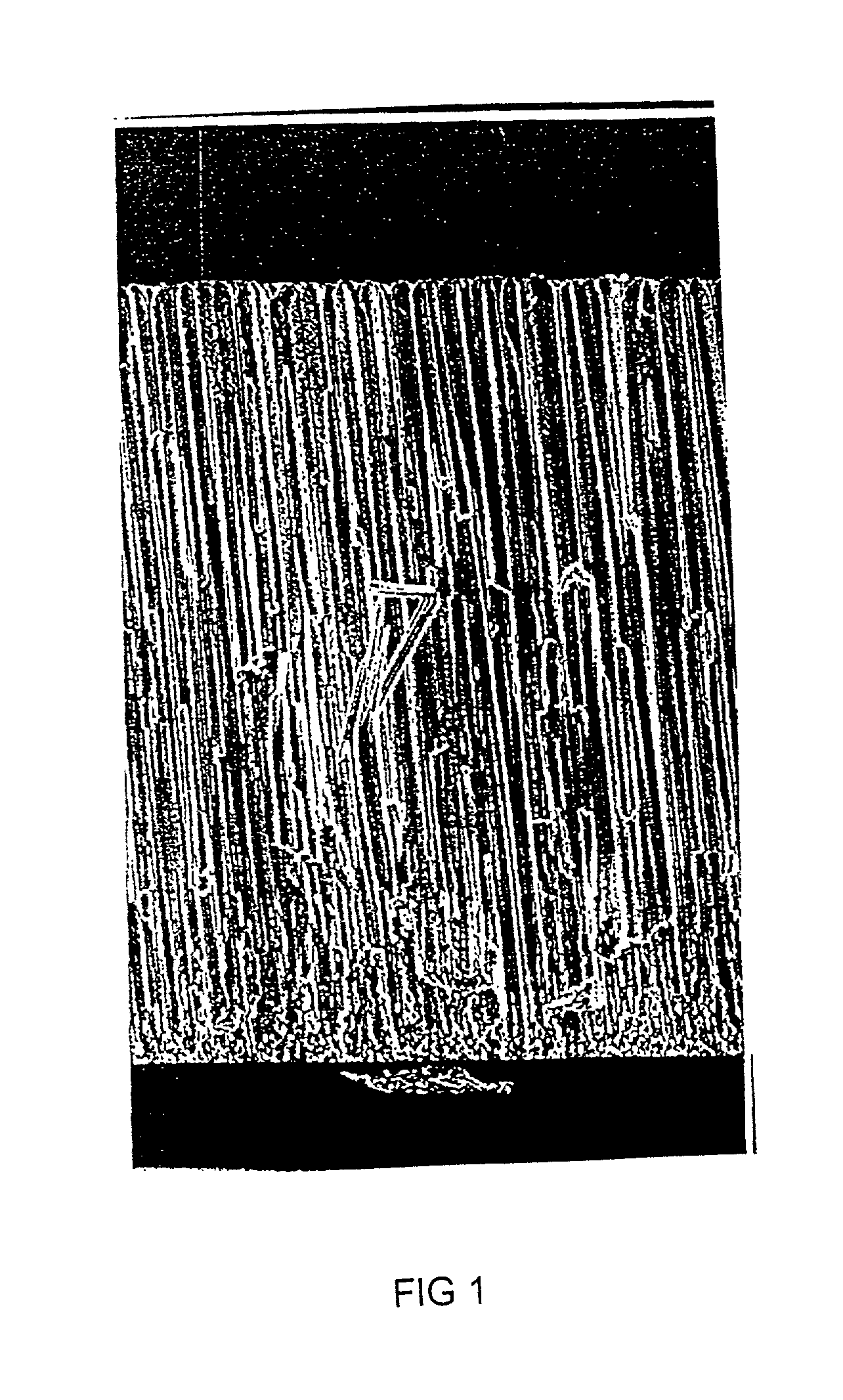

[0051] Via Scanning Elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| Ar-pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com