Method for dynamically re-dispatching job shop multi-process routes in batches based on two-stage differential evolution algorithm

A differential evolution algorithm and job shop technology, applied in genetic models, comprehensive factory control, comprehensive factory control, etc., can solve problems such as unbalanced capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] In combination with the technical scheme and the accompanying drawings, the specific implementation manner of the present invention will be described in detail.

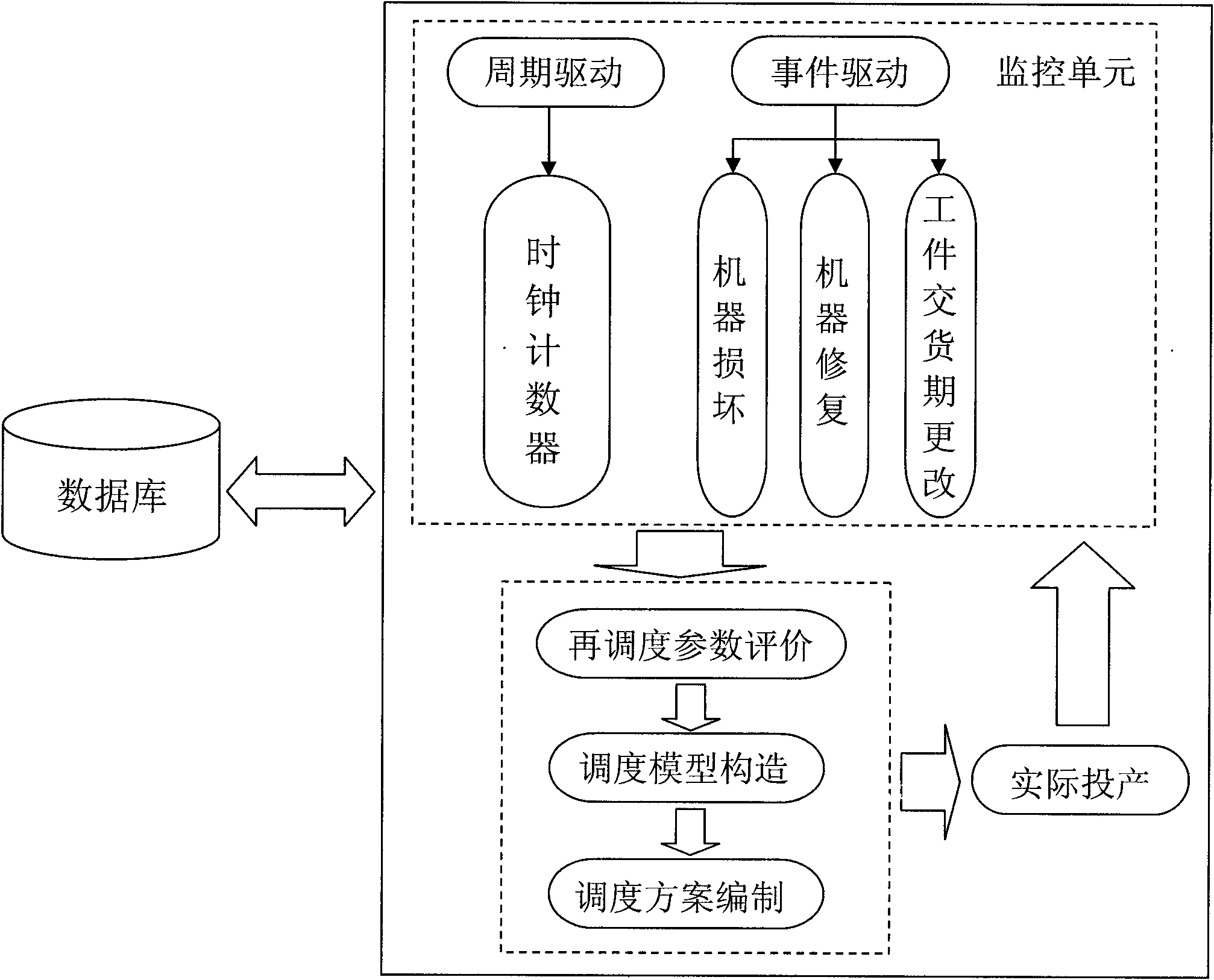

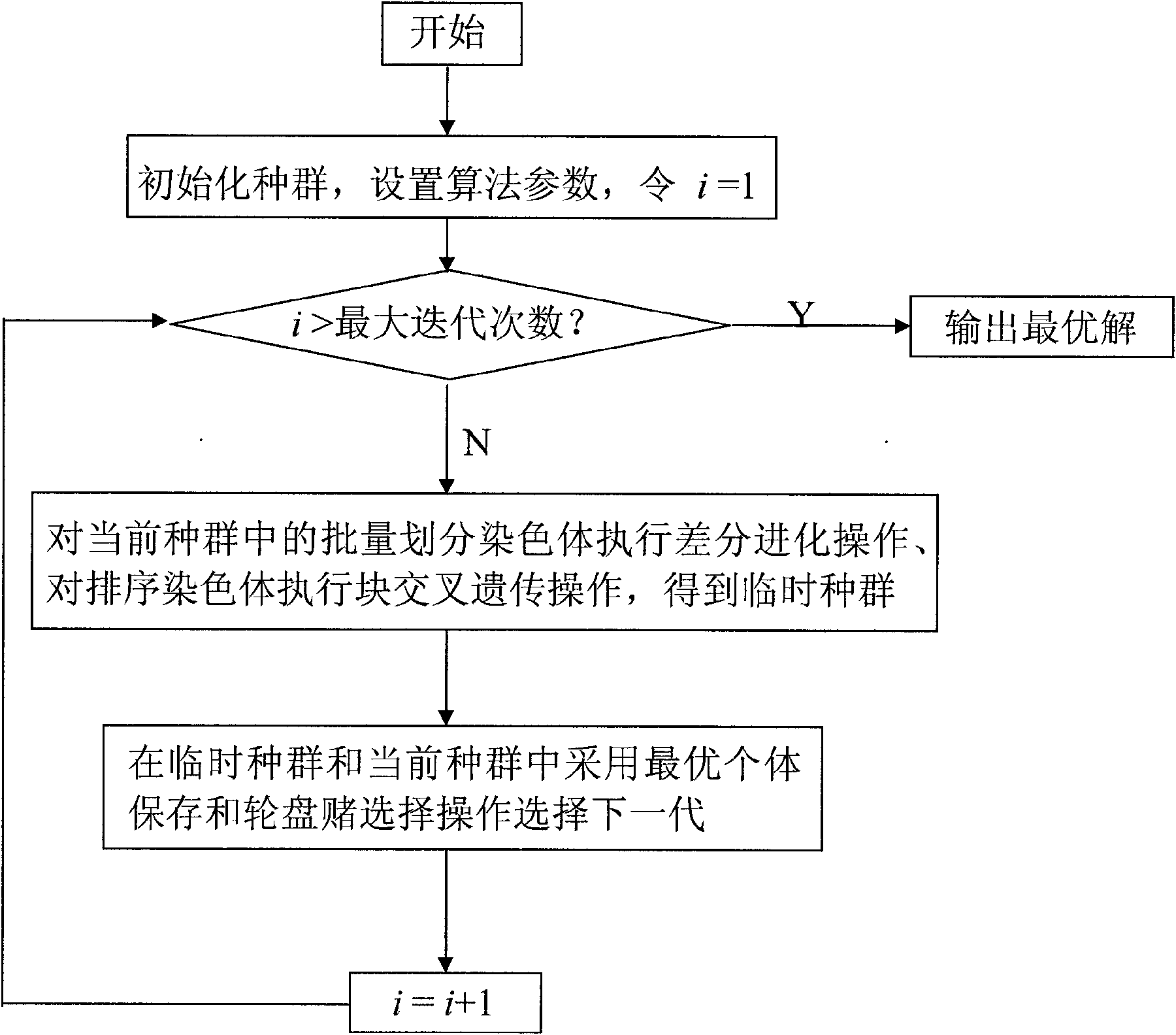

[0084] Refer to attached Figure 1 to Figure 8 , a batch dynamic rescheduling method for multi-process routes in a job shop based on a two-level differential evolution algorithm, including the following steps:

[0085] Step 1: Determine whether the clock counter reaches the cycle time point, if it reaches the cycle time point, take this time point as the rescheduling time starting point t 0 , execute step 2; otherwise, judge whether there is an emergency event, if an emergency event occurs, take the event occurrence time as the starting point of rescheduling time and execute step 2.

[0086] The dynamic environment studied by the present invention includes the following emergencies: the machine is suddenly damaged; the damaged machine is repaired; the order information is changed and so on.

[0087] Step 2: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com