Intelligent crane scheduling method for multi-material storage

A scheduling method and crane technology, applied in the field of crane mechanical control, can solve problems such as the inability to guarantee the logistics process and optimization of intelligent warehouse areas, and achieve the effects of strong technical flexibility, strong versatility, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical solutions and advantages of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

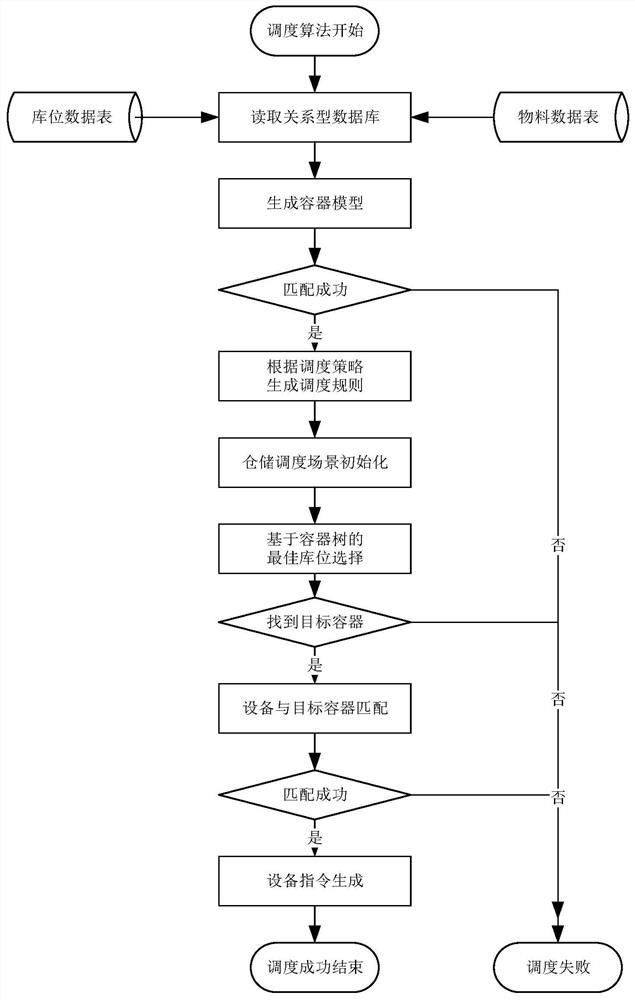

[0024] Such as figure 1 An intelligent crane scheduling method suitable for storage of various materials is shown, and the specific method is as follows:

[0025] S1: Read relational database: including location data loading, material data loading and crane equipment status data loading.

[0026] S2: Generate a container tree model, where a container refers to a spatial logic description when a specified location is filled with materials, and the containment relationship between containers forms a parent-child structure, thereby forming a container tree. Inclusion relationship:

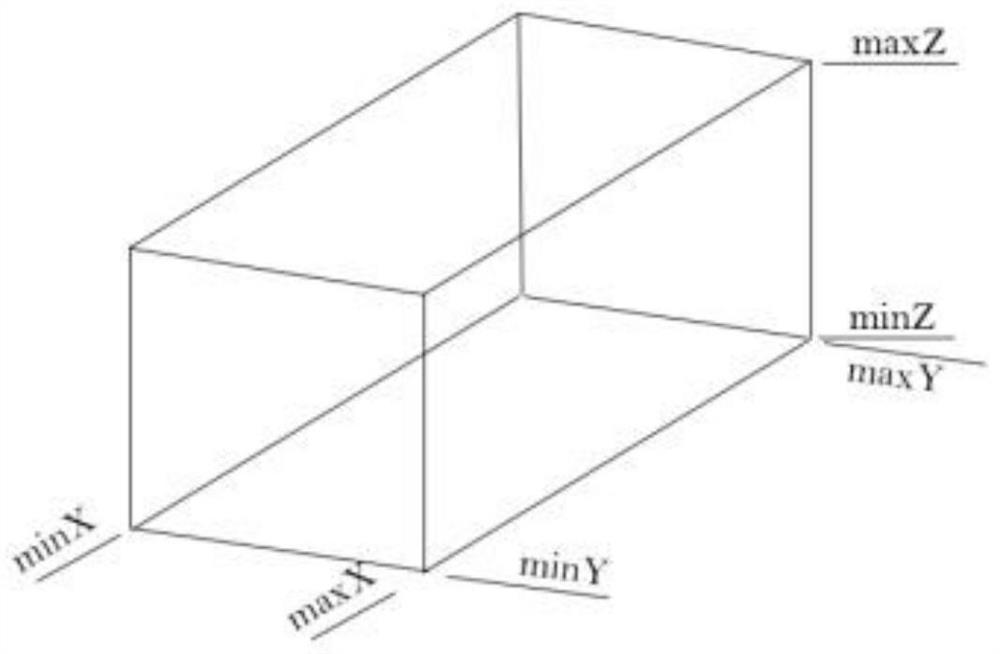

[0027] The attributes of the container model include: parent container, child container, AABB bounding box,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com