Medical anesthetic needle

a technology of anesthetic needles and needles, which is applied in the direction of guide needles, infusion needles, catheters, etc., can solve the problems of patient pain when needled, insufficient pain relief, and patients often feeling pain when needled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

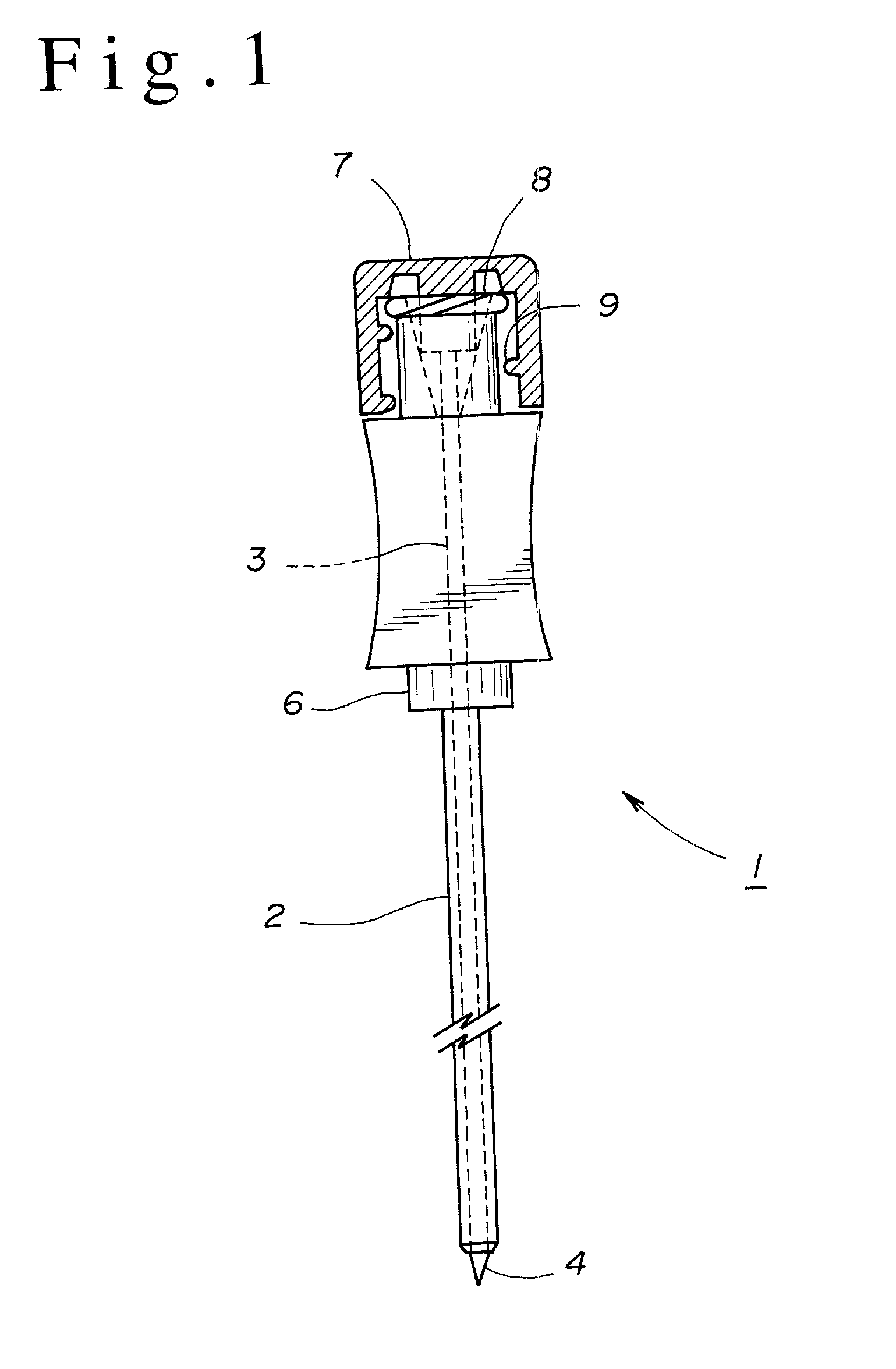

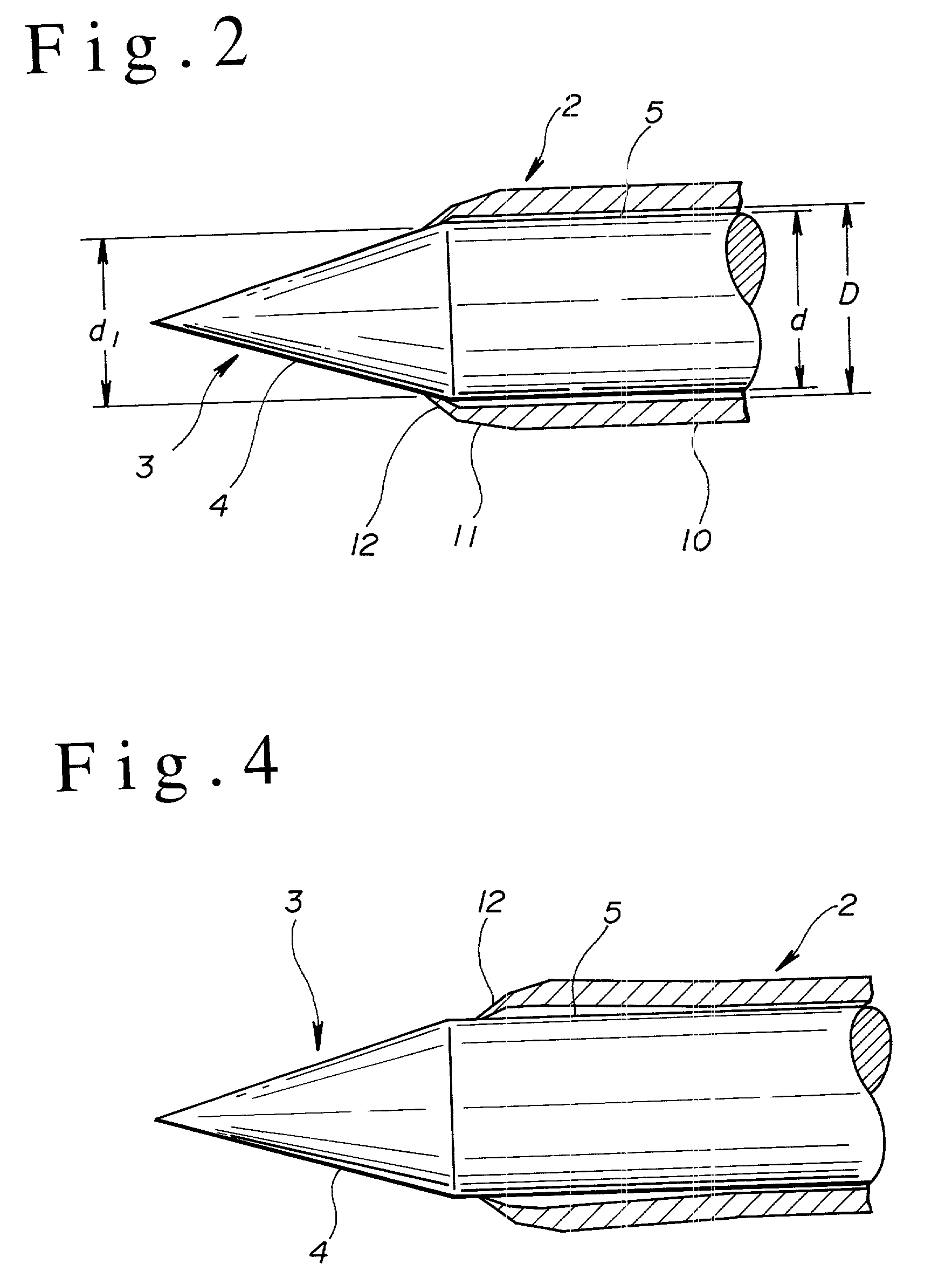

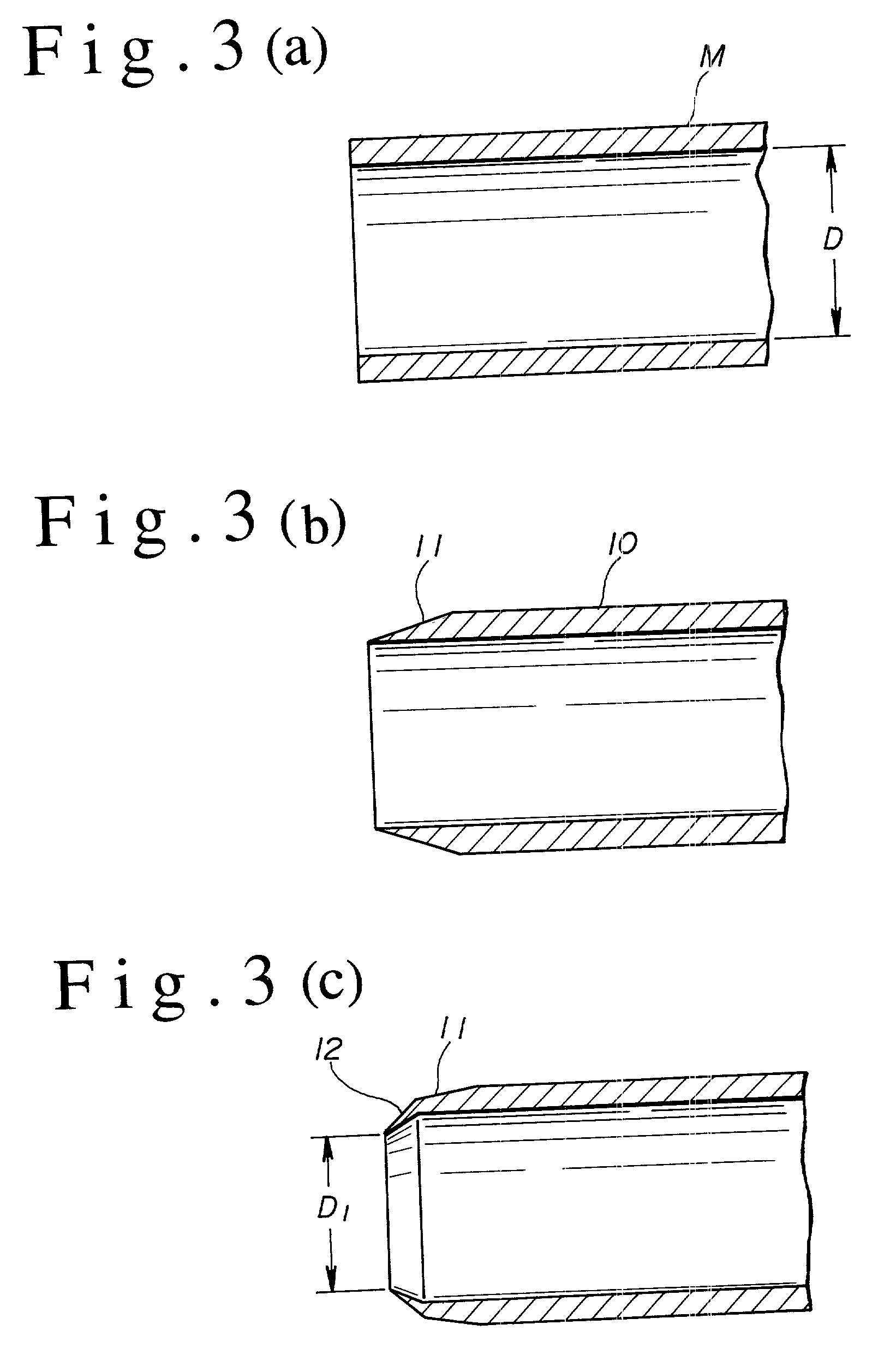

[0013] As shown in FIG. 1, an anesthetic needle 1 includes a hollow outer needle 2 made of stainless steel tube and a solid inner needle 3 made of stainless steel bar. The rear end of the outer needle 2 is fixed to a needle base 6. The inner needle 3 is inserted through a needle hole of the needle base 6 into the outer needle 2. A tip 4 of the inner needle 3 that protrudes from the fore end of the outer needle 2 is of a pencil-pointed shape, i.e., a conical shape. A cap 7 is fixed to the rear end of the inner needle 3, where a spiral-shaped female screw part 9 is formed on the internal circumferential surface of the cap 7. A spiral-shaped male screw part 8 that engage's with the female screw part 9 of the cap 7, is disposed on a section protruding from the rear end of the needle base 6. When inserting the anesthetic needle, the male screw part 8 is screwed into the female screw part 9 to the limit, to define the axial limit position of the inner needle 3 relative to the outer needle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com