Electrode material for all-vanadium redox flow battery and preparation method thereof

An all-vanadium redox flow battery and electrode material technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as battery performance constraints, reduced battery performance, and high resistivity, so as to improve electrochemical reversibility and improve performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

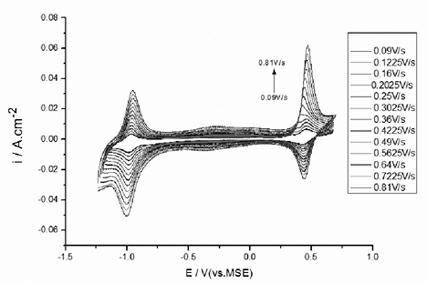

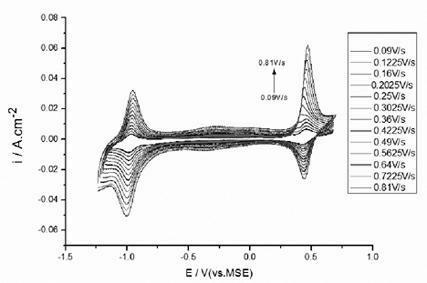

Image

Examples

Embodiment 1

[0016] Embodiment 1: The electrode material for the all-vanadium redox flow battery is prepared by the following method.

[0017] (1) Heat acetylene black to 800°C at a heating rate of 5°C / min in a heating device and keep it warm for 2 hours. After cooling to room temperature naturally, wash, filter and dry with distilled water.

[0018] (2) Add 1.4g Na 2 WO 4 2H 2 O was dissolved in 14mL water, and a sodium tungstate solution with a mass concentration of 9% was prepared, and 1g of oxidized acetylene black was added (the molar ratio of sodium tungstate and acetylene black was 0.05:1). Add 16mL of 4mol / L hydrochloric acid dropwise at a speed of 1 / min, the pH of the solution is 1, after all the hydrochloric acid is added, continue to stir for 0.5h, then stand and age at room temperature for 12 hours, then perform suction filtration, washing, and drying.

[0019] (3) Then put it into the muffle furnace and raise the temperature to 500°C at a heating rate of 5°C / min and keep it...

Embodiment 2

[0020] Example 2: The electrode material for the all-vanadium redox flow battery is prepared by the following method.

[0021] (1) Heat acetylene black to 700°C at a heating rate of 2°C / min in a heating device and keep it warm for 2 hours. After cooling to room temperature naturally, wash, filter and dry with distilled water.

[0022] (2) Add 1.4g Na 2 WO 4 2H 2 O was dissolved in 14mL of water to prepare a sodium tungstate solution with a mass concentration of 9%, and 1g of oxidized acetylene black was added (the molar ratio of sodium tungstate and acetylene black was 0.05:1). Add 16 mL of 3 mol / L hydrochloric acid dropwise at a speed of 1 / min, the pH of the solution is 1, after adding all the hydrochloric acid, continue to stir for 2 hours, leave it to stand at room temperature for 24 hours, then carry out suction filtration, washing, and drying.

[0023] (3) Then put it into the muffle furnace and raise the temperature to 400°C at a heating rate of 8°C / min and keep it fo...

Embodiment 3

[0024] Embodiment 3: The electrode material for the all-vanadium redox flow battery is prepared by the following method.

[0025] (1) Heat acetylene black to 600°C at a heating rate of 10°C / min in a heating device and keep it warm for 1.5h. After cooling to room temperature naturally, wash, filter and dry with distilled water.

[0026] (2) Add 2.8g Na 2 WO 4 2H 2 O was dissolved in 16mL of water to prepare a sodium tungstate solution with a mass concentration of 14.9%. Add 1g of oxidized acetylene black (the molar ratio of sodium tungstate to acetylene black was 0.1:1), and under magnetic stirring, 3mL Add 12mL of 4mol / L hydrochloric acid dropwise at a speed of 1 / min, the solution pH=2, after adding all the hydrochloric acid, continue to stir for 4h, leave to stand and age at room temperature for 8 hours, then carry out suction filtration, washing, and drying.

[0027] (3) Put it into a muffle furnace and raise the temperature to 200°C at a rate of 2°C / min and keep it warm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com